Method of manufacturing porous metal mold for wet pulp molding process

A technology of metal molds and manufacturing methods, applied in the field of porous metal sintered molds, can solve problems such as difficult to remove, easy to block, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail as follows. The patent scope of the present invention is not limited to the above-mentioned embodiments, and should be defined by the patent scope of the application.

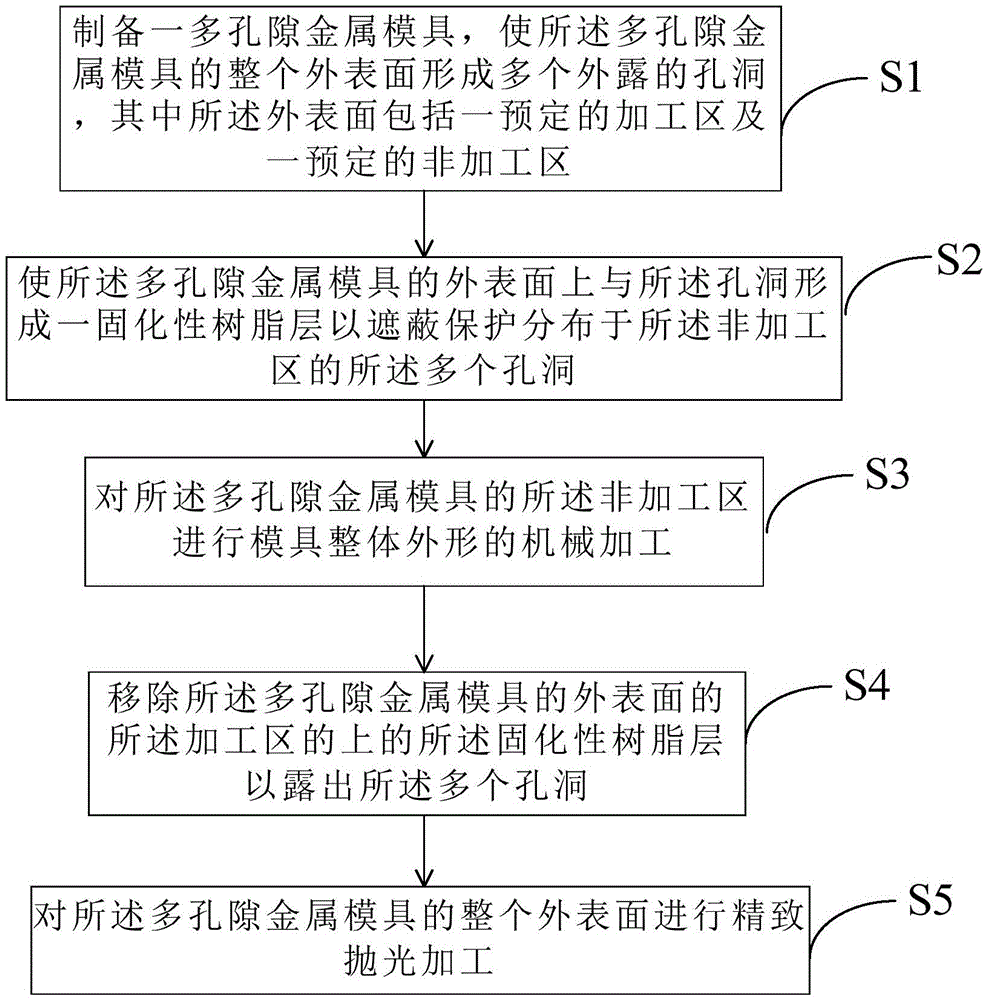

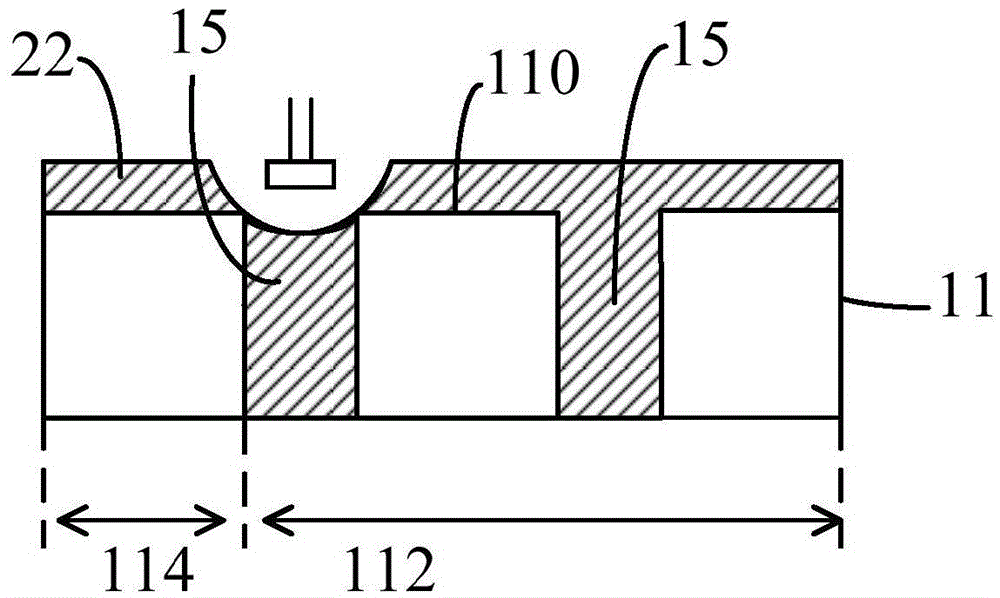

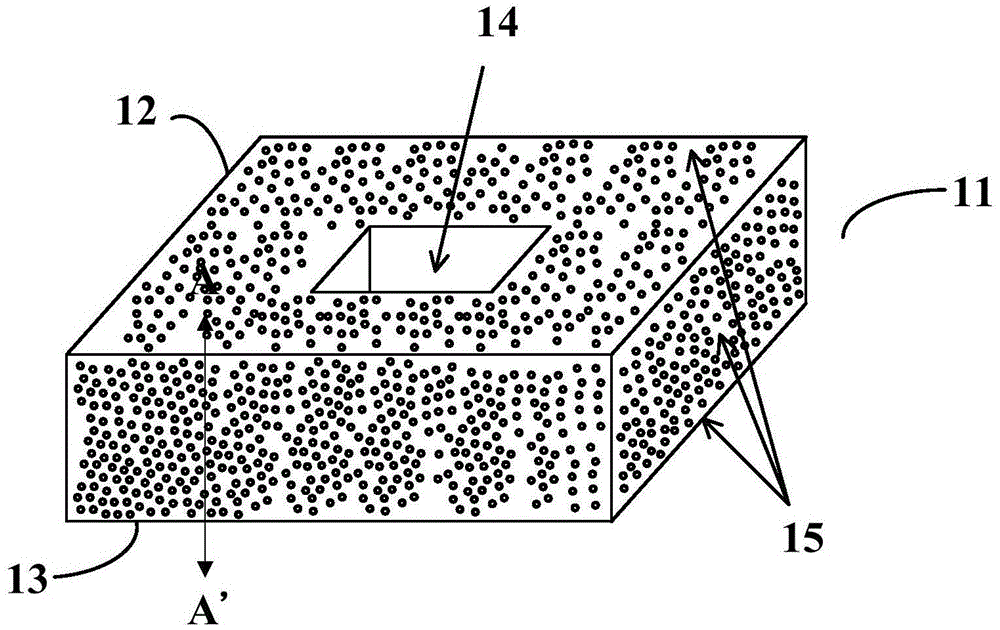

[0028] Please refer to Figure 1A and 1B picture, Figure 1A It is a flowchart of a method for manufacturing a porous metal mold according to a preferred embodiment of the present invention, the manufacturing method includes the following steps: (S1) preparing a porous metal mold 11, making the porous metal mold 11 The entire outer surface 110 forms a plurality of exposed holes 15, wherein the outer surface 110 includes a predetermined processing area 112 and a predetermined non-processing area 114; (S2) making the outer surface 110 of the porous metal mold 1 Forming a curable resin layer 22 with the holes 15 to shield and protect the plura...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com