A Longitudinal-Torsion Compound Ultrasonic Vibration Cutting Device

A composite ultrasonic and vibration cutting technology, used in fine working devices, milling machine equipment, stone processing equipment, etc., can solve the problems of surface roughness reducing cutting force, complex structure, difficult to control, etc., to improve processing performance, control Easy, time-saving and labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

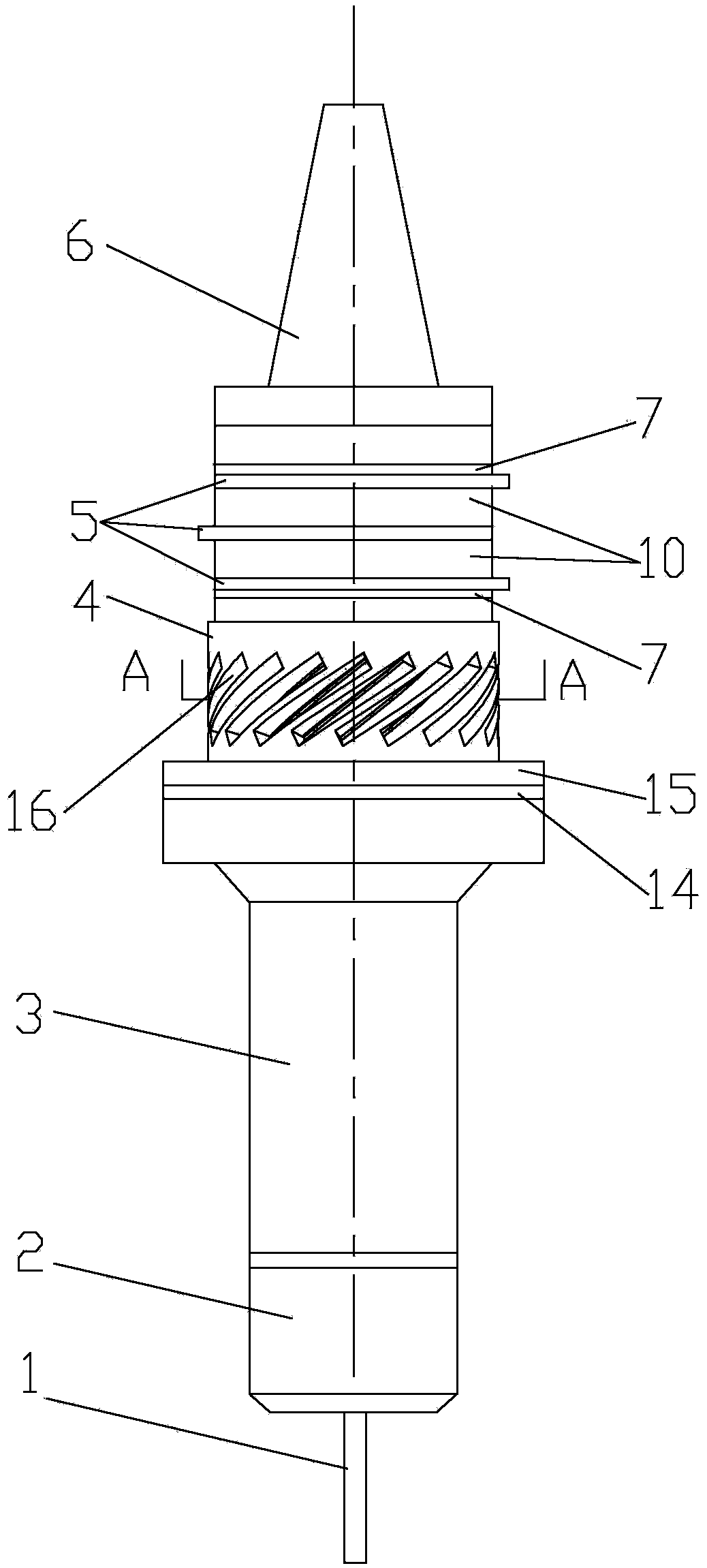

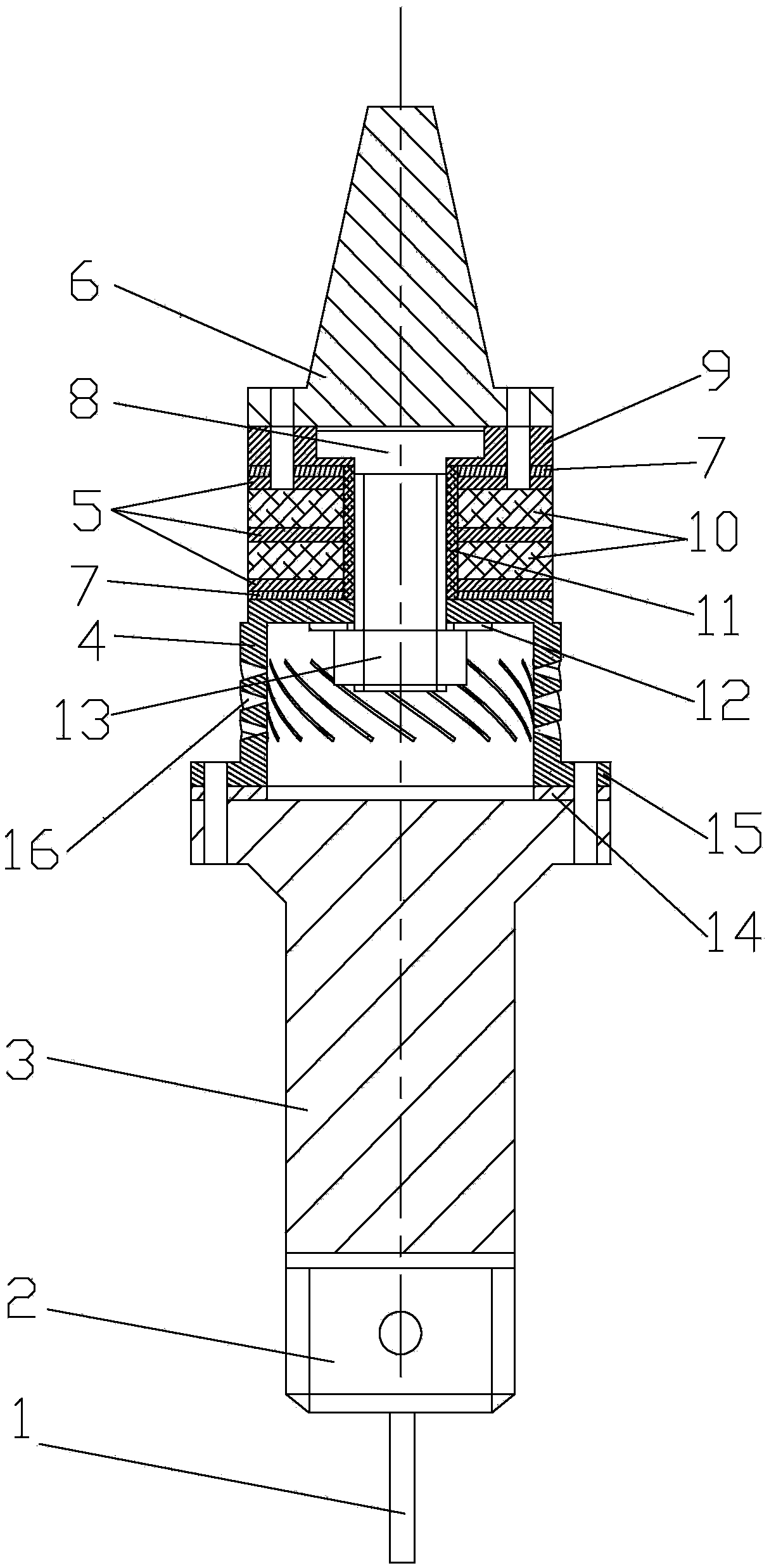

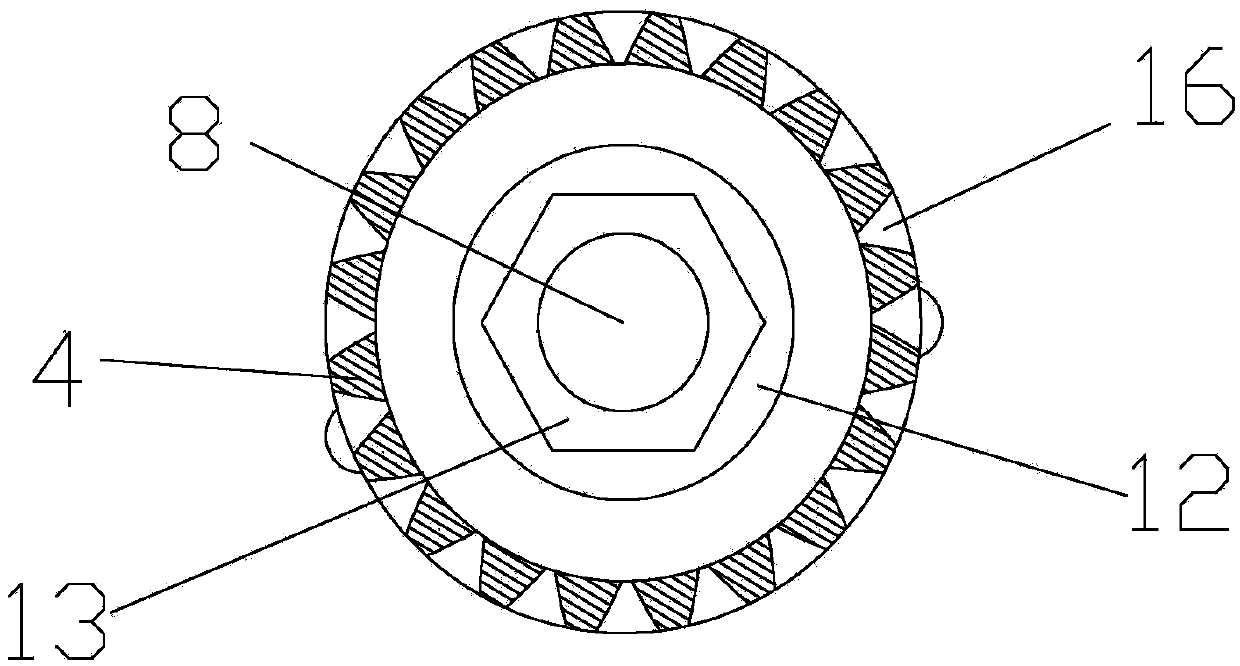

[0019] Such as Figure 1 ~ Figure 3 As shown, a longitudinal-torsion composite ultrasonic vibration cutting device includes a processing tool 1 coaxially arranged, an ultrasonic vibration longitudinal-torsion spindle system and a clamping taper handle 6, and the ultrasonic vibration longitudinal-torsion spindle system is composed of a pre-tightening bolt 8 and a positioning chuck 9 , electrode sheet 5, insulating sheet 7, insulating sleeve 11, piezoelectric ceramic sheet 10, twisted horn body 4, horn 3 and collector ring 14, collector ring 14 is arranged on the top of horn 3, twisted The horn 4 is arranged on the top of the collector ring 14. The twisted horn 4 is an inverted cylindrical structure. On the outer wall of the twisted horn 4, a grid group 16 is arranged along the circumferential direction. The grids Group 16 is a plurali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com