Casting process for high-temperature water-pressure-resisting combined flange

A casting process and combined technology, which is applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of cracks, blisters, and increased production costs in steel castings, so as to eliminate stress, improve toughness, and ensure high The effect of hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

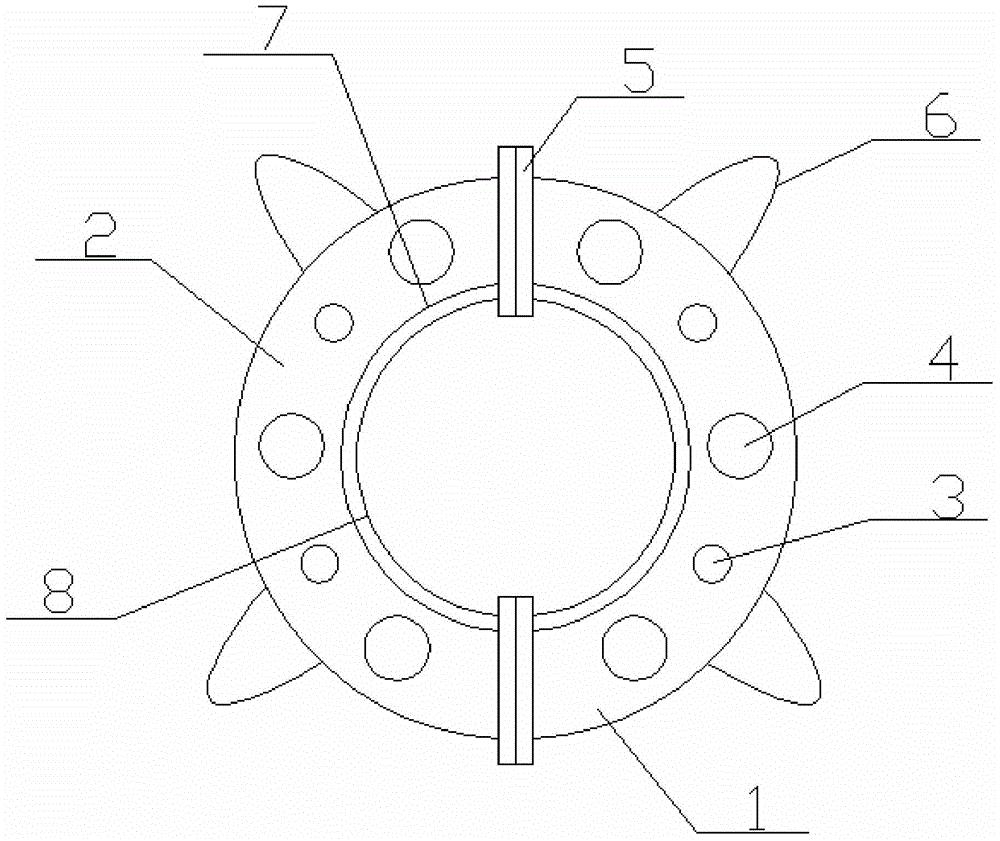

[0045] This example provides a casting process for a high-temperature and water-pressure-resistant combined flange, which casts a high-temperature wear-resistant combined flange structure such as figure 1 As shown, the high-temperature wear-resistant combined flange mainly includes a flange body, the flange body is composed of a first flange 1 and a second flange 2, and the second flange 2 and the first flange 1 are about Set symmetrically, and the shape and size of the second flange 2 are consistent with the first flange 1, wherein:

[0046] Both the first flange 1 and the second flange 2 are of saddle-shaped structure, and the first flange 1 is evenly distributed with threaded holes 3 and through holes 4, and the threaded holes 3 and through holes 4 are spaced apart. The two ends of a flange 1 respectively extend outward to form a fixed side 5, the fixed side 5 is provided with a fixing hole, and at least two lugs 6 are provided on the outer edge of the first flange 1;

[0...

Embodiment 2

[0064] This embodiment provides the casting process of the high temperature and water pressure resistant combined flange of embodiment 1,

[0065] The casting process of the flange body specifically includes the following steps:

[0066] (1) According to the size of the flange body, sea sand, bentonite, additives and water are used as molding materials to mix the mold in the sand box, and the rough surface of the mold is sequentially painted, sanded, air-dried, hardened and air-dried. The dry process obtains the casting mold of the flange body for use;

[0067] The molding materials are as follows in terms of mass percentage: sea sand: 80%, water glass 5%, bentonite: 4%, dextrin: 1%, and water 10%, sea sand is 50 mesh sea sand;

[0068] 270-mesh quartz powder paint is applied to the surface of the casting mold, and chromite resin sand with a thickness of 20mm is sprinkled when sanding;

[0069] (2) Smelt the raw material of the flange body to obtain the raw material liquid. ...

Embodiment 3

[0081] This embodiment provides the casting process of the high temperature and water pressure resistant combined flange of embodiment 1,

[0082] The casting process of the flange body specifically includes the following steps:

[0083] (1) According to the size of the flange body, sea sand, bentonite, additives and water are used as molding materials to mix the mold in the sand box, and the rough surface of the mold is sequentially painted, sanded, air-dried, hardened and air-dried. The dry process obtains the casting mold of the flange body for use;

[0084] The molding materials are as follows in terms of mass percentage: sea sand: 80%, water glass 5%, bentonite: 4%, dextrin: 1%, and water 10%, sea sand is 60 mesh sea sand;

[0085] 270-mesh quartz powder paint is applied to the surface of the casting mold, and chromite resin sand with a thickness of 35mm is sprinkled when sanding;

[0086] (2) Smelt the raw material of the flange body to obtain the raw material liquid. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com