Amino-functionalized adsorption agent and preparation method thereof

An amine functionalization and adsorbent technology, applied in the field of molecular sieves, can solve problems such as poor adsorption and removal, and achieve the effects of efficient adsorption, increasing load capacity, and avoiding loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The present invention also provides a preparation method of amine functionalized adsorbent, comprising the following steps:

[0046] A) mixing an alkylamine template, tetraethylorthosilicate and a doping modifier in a solvent for doping modification to obtain a doping-modified HMS molecular sieve;

[0047] The doping modifier includes one or more of Zr precursors, Ti precursors and Al precursors;

[0048] B) using an organic amine modifier to modify the doped modified HMS molecular sieve to obtain an amine functionalized adsorbent;

[0049] The organic amine modifier includes one or more of tetraethylenepentamine, pentaethylenehexamine, polyethylenepolyamine, and polyethyleneimine.

[0050] In the present invention, the alkylamine template is preferably added into the solvent, stirred evenly, and then tetraethyl orthosilicate (TEOS) and the doping modifier are added, and the doping modification is carried out under stirring conditions to obtain the doped Modified HMS ...

Embodiment 1

[0062] The doping modification of HMS molecular sieve can be realized by replacing a certain proportion of tetraethyl orthosilicate with a doping modifier. press n 异丙醇铝 :n 正硅酸乙酯 :n 十二烷基胺 :n CH3CH2OH :n H2O =0.03::0.97:0.27:6.50:36.00 molar ratio Add dodecylamine templating agent into 400ml water-ethanol solvent, stir well at 40°C, then slowly add tetraethyl orthosilicate (TEOS) and iso Aluminum propoxide, continued to stir for 24 hours, and vacuum-dried to obtain an Al-doped modified HMS molecular sieve (3Al-DDA-HMS).

[0063] Dissolve 1g polyethyleneimine (PEI) in methanol solution, stir at room temperature for 60min, add 4g of 3Al-DDA-HMS, stir for another 6h, and vacuum dry to obtain 20PEI / 3Al-DDA-HMS adsorbent.

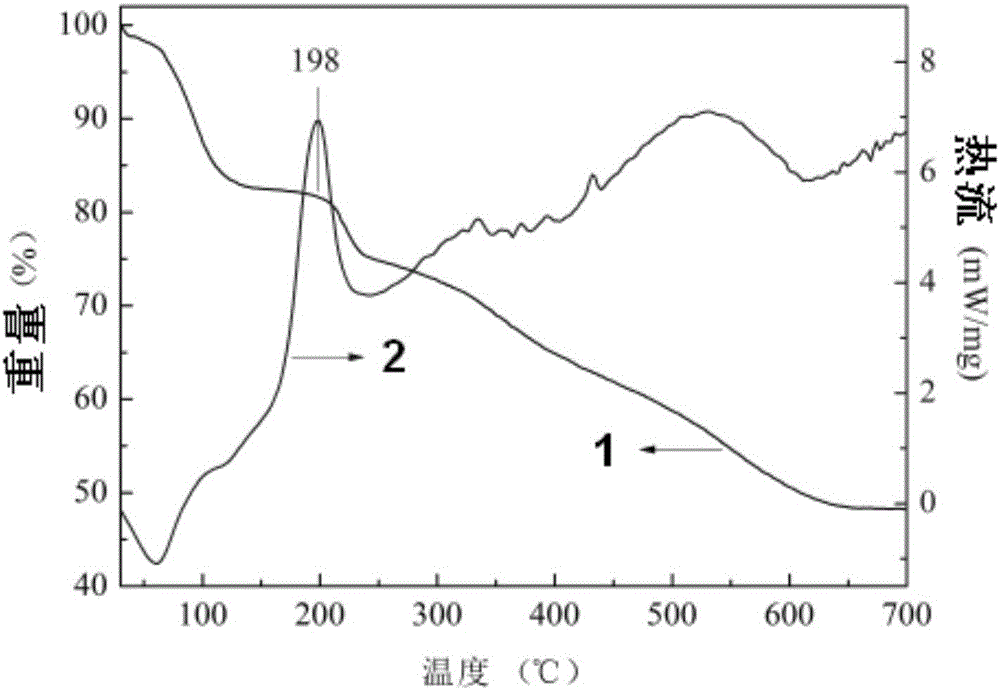

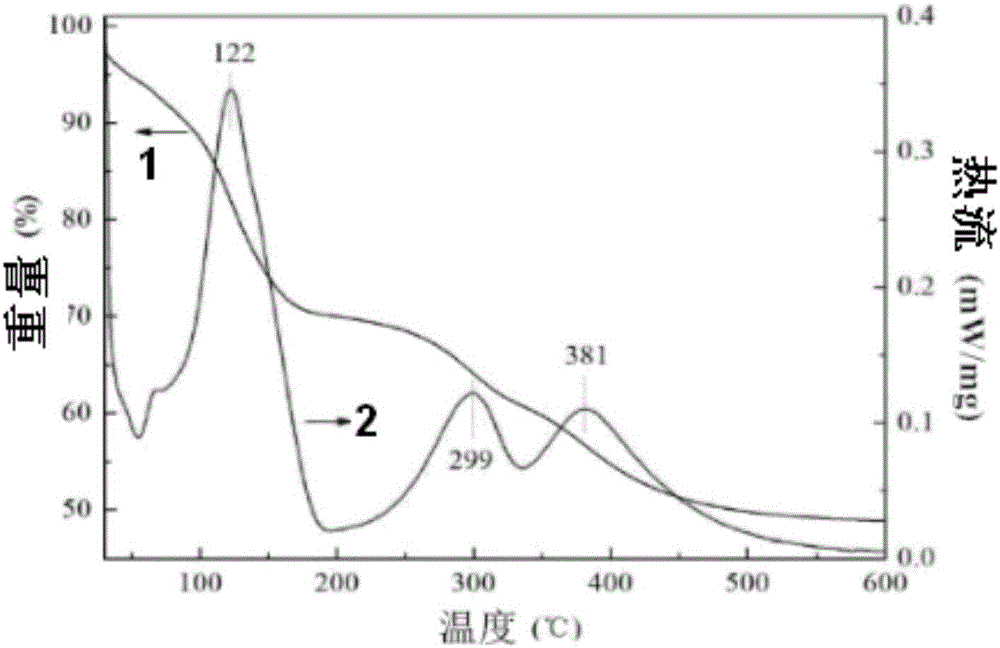

[0064] In the experiment, the adsorption capacity of 20PEI / 3Al-DDA-HMS was tested by referring to the national standard GB6287-86 molecular sieve static water adsorption determination method. First, vacuum-dry the adsorbent in an oven at 105°C for 24 hours, ...

Embodiment 2

[0067] press n 氯氧化锆 :n 正硅酸乙酯 :n 十二烷基胺 :n CH3CH2OH :n H2O =0.05::0.95:0.27:7:36.00 molar ratio Add dodecylamine (DDA) into a mixed solution of 300ml water and ethanol, stir well at 50°C, slowly add tetraethyl orthosilicate (TEOS) and Zirconium oxychloride, continue stirring for 12 hours, and vacuum-dry to obtain doped modified HMS molecular sieve (5Zr-DDA-HMS). Finally, dissolve 1.7143g of pentaethylenehexamine (PEHA) in methanol solution, stir at room temperature for 30min, add 4g of 5Zr-DDA-HMS, stir for another 2h, and vacuum dry to obtain 30PEHA / 5Zr-DDA-HMS.

[0068] In the experiment, the static water absorption capacity of 30PEHA / 5Zr-DDA-HMS is 15%, which is 12% higher than that of the 5Zr-DDA-HMS sample modified without amine loading; the decomposition temperature of 30PEHA / 5Zr-DDA-HMS in the experiment is 187°C, which is 82°C higher than that of the 30PEHA / DDA-HMS sample modified without zirconium doping.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Decomposition temperature | aaaaa | aaaaa |

| Decomposition temperature | aaaaa | aaaaa |

| Decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com