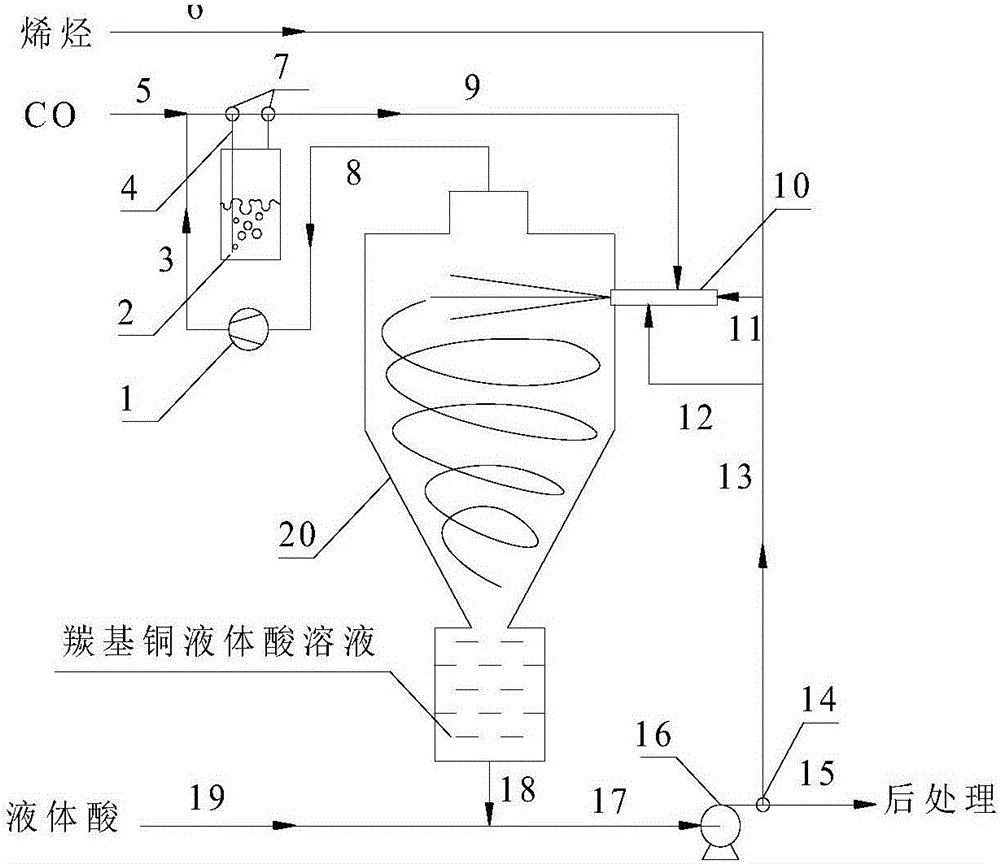

Centrifugal inner swirl type multiphase jetting reactor and method for preparing tert-carbonic acid with centrifugal inner swirl type multiphase jetting reactor

A jet reactor and reactor technology, applied in the preparation of carboxylic acid by carbon monoxide reaction, chemical instruments and methods, organic chemistry, etc., can solve problems such as low production efficiency, high energy consumption, and easy agglomeration of copper carbonyl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

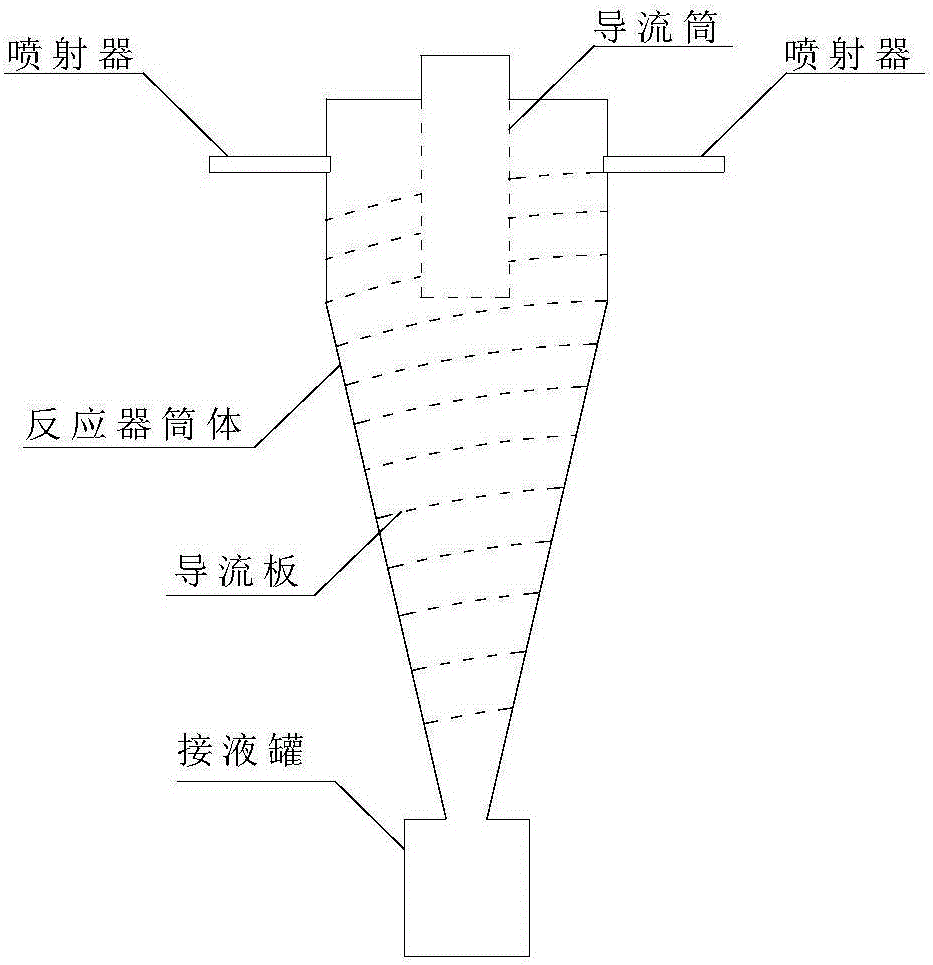

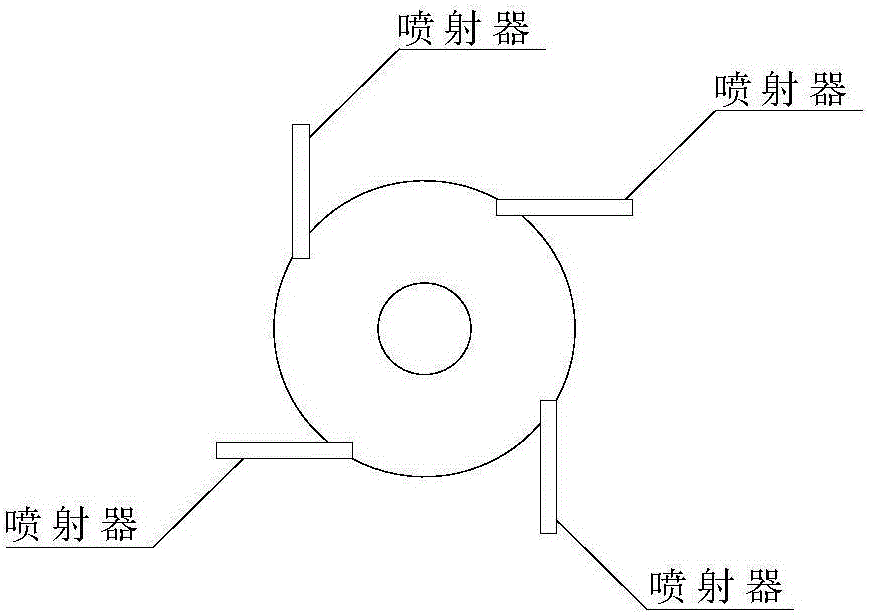

[0063] The reactor is a centrifugal internal swirl reactor with 2 injectors. The injector is perpendicular to the axis of the reactor and forms an angle of 85° with the tangent line of the outer circle of the reactor. The height ratio of the cylinder at the upper end of the reactor to the cone at the lower end is The ratio of the height of the reactor to the diameter of the cylinder is 50:1, the diameter of the cylinder is 500mm, the diameter of the connection between the liquid tank and the bottom of the cone is 1 / 10 of the diameter of the cylinder, and the inner diameter of the main body of the liquid tank is 2 times the inner diameter of the interface. On the inner wall of the reactor, there is a deflector extending from the lower edge of the injector insertion port to the bottom. The inclination angle between the downward direction and the horizontal plane is 60°. The cross section of the deflector is rectangular, and the width is 1% of the diameter of the reactor. The rat...

Embodiment 2

[0067] A centrifugal internal swirl reactor is used for the reaction, and 4 injectors are set up. The injectors are perpendicular to the axis of the reactor and form an angle of 75° with the tangent line of the outer circle of the reactor. The height ratio of the cylinder at the upper end of the reactor to the cone at the lower end is 1:5, the ratio of the height of the reactor to the diameter of the cylinder is 40:1, the diameter of the cylinder is 200mm, the diameter of the connection between the liquid tank and the bottom of the cone is 1 / 10 of the diameter of the cylinder; the inner diameter of the main body of the liquid tank is the interface 5 times the inner diameter. On the inner wall of the reactor, there is a deflector extending from the lower edge of the injector insertion port to the bottom. The inclination angle between the downward direction and the horizontal plane is 50°. The deflector has a rectangular cross-section and a width of 2% of the diameter of the reac...

Embodiment 3

[0071] A centrifugal internal swirl reactor is used for the reaction, and 6 injectors are set. The injectors are perpendicular to the axis of the reactor and form an angle of 60° with the tangent line of the outer circle of the reactor. The height ratio of the cylinder at the upper end of the reactor to the cone at the lower end is 1:3, the ratio of the height of the reactor to the diameter of the cylinder is 20:1, the diameter of the cylinder is 300mm, the diameter of the connection between the liquid tank and the bottom of the cone is 1 / 15 of the diameter of the cylinder; the inner diameter of the main body of the liquid tank is the interface 10 times the inner diameter. The inner wall of the reactor is provided with a deflector extending from the lower edge of the injector insertion port to the bottom. The inclination angle between the downward direction and the horizontal plane is 30°. The deflector has a rectangular cross-section and a width of 2% of the diameter of the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com