A kind of graphene oxide intelligent drug carrier that can be sensitively shed by supramolecules and its preparation method and application

A graphene and supramolecular technology, applied in the field of preparation of nano-carriers, can solve the problems of hindering the rapid release of drugs, inability to be sensitive to shedding, etc., and achieve the effects of improving drug release rate and drug loading rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

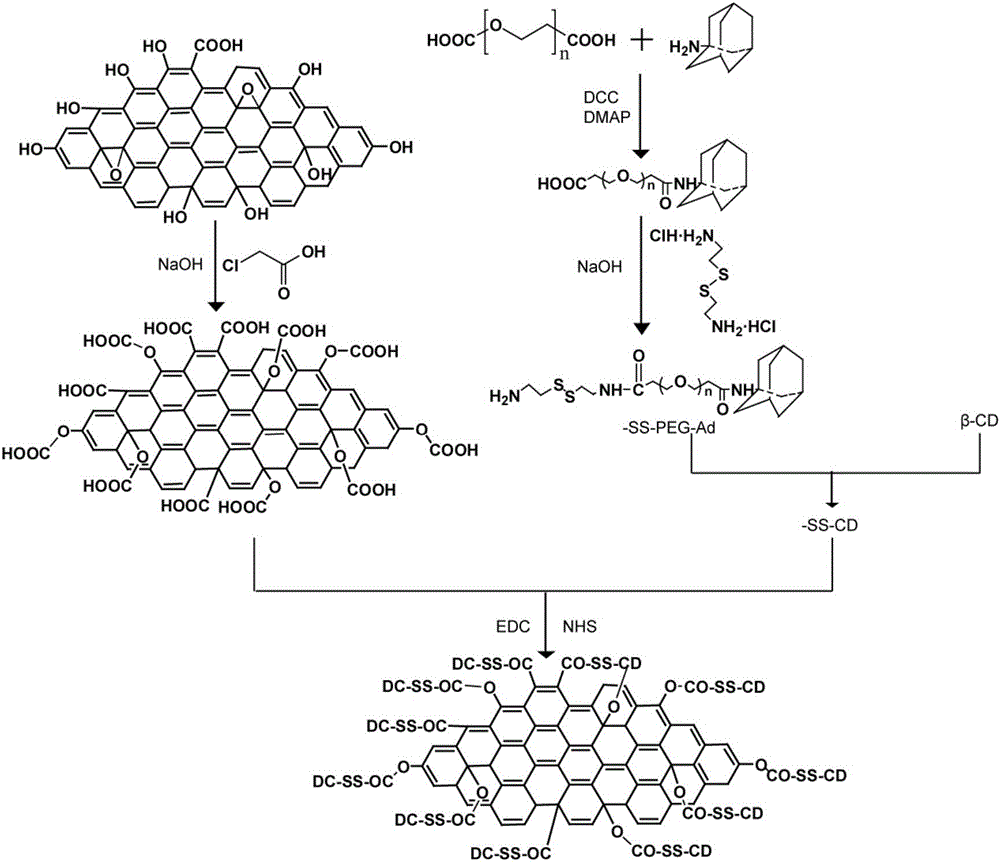

[0049] see figure 1 , a kind of preparation method of the graphene oxide smart drug carrier that supramolecule can be sensitive to come off, comprises the following steps:

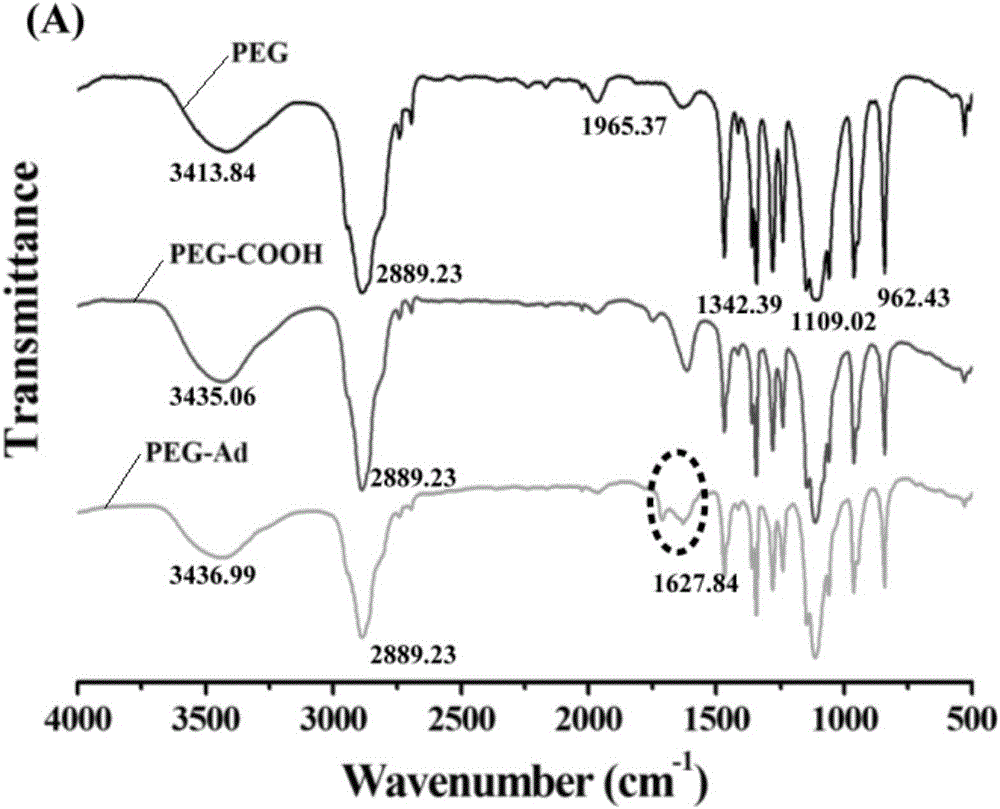

[0050] (1) Carboxylation of polyethylene glycol

[0051] Polyethylene glycol (PEG, Mw=2000, 99% purity, 2.0 mmol) was placed in a round bottom flask, and then 30 mL of dimethyl sulfoxide was added to the round bottom flask to dissolve the polyethylene glycol. Add 10 mL of 40% NaOH solution and 20 mmol of chloroacetic acid. After stirring and reacting at room temperature for 10 h, the solvent was distilled off under reduced pressure, and then 100 mL of anhydrous dichloromethane was added thereto. Filtration to remove salt, rotary evaporation to concentrate the filtrate to obtain a concentrated solution, the concentrated solution was added to cold ether, precipitation occurred, and a white solid was obtained by suction filtration, and the obtained white solid was vacuum-dried at 30°C to obtain carboxylatio...

Embodiment 2

[0064] A kind of preparation method of the graphene oxide intelligent drug carrier that supramolecule can fall off sensitively, comprises the following steps:

[0065] (1) Carboxylation of polyethylene glycol

[0066] Polyethylene glycol (PEG, Mw=2000, 99% purity, 2.0 mmol) was placed in a round bottom flask, and then 25 mL of dimethyl sulfoxide was added to the round bottom flask to dissolve the polyethylene glycol. Add 15 mL of 40% KOH solution and 20 mmol of chloroacetic acid. After stirring the reaction at room temperature for 12 h, the solvent was distilled off under reduced pressure, and then 150 mL of anhydrous dichloromethane was added thereto. Filtration to remove salt, rotary evaporation to concentrate the filtrate to obtain a concentrated solution, the concentrated solution was added to cold ether, precipitation occurred, and a white solid was obtained by suction filtration, and the obtained white solid was vacuum-dried at 30°C to obtain carboxylation Polyethylene...

Embodiment 3

[0080] A kind of preparation method of the graphene oxide intelligent drug carrier that supramolecule can fall off sensitively, comprises the following steps:

[0081] (1) Carboxylation of polyethylene glycol

[0082] Polyethylene glycol (PEG, Mw=2000, 99% purity, 2.0 mmol) was placed in a round bottom flask, and then 35 mL of dimethyl sulfoxide was added to the round bottom flask to dissolve the polyethylene glycol. Add 10 mL of 40% NaOH solution and 20 mmol of chloroacetic acid. After stirring the reaction at room temperature for 15 h, the solvent was distilled off under reduced pressure, and then 120 mL of anhydrous dichloromethane was added thereto. Filtration to remove salt, rotary evaporation to concentrate the filtrate to obtain a concentrated solution, the concentrated solution was added to cold ether, precipitation occurred, and a white solid was obtained by suction filtration, and the obtained white solid was vacuum-dried at 30°C to obtain carboxylation Polyethylen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com