Monitoring and feedback control system for laser output stability

A feedback control system and stability technology, applied in the direction of lasers, photometry, laser devices, etc., can solve the problems that the optical system cannot be guaranteed to be normal and stable, and the feedback calibration control cannot be achieved, so as to achieve compact structure and fast feedback adjustment speed , System flexible and variable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The directions shown in the accompanying drawings are up, down, left, and right.

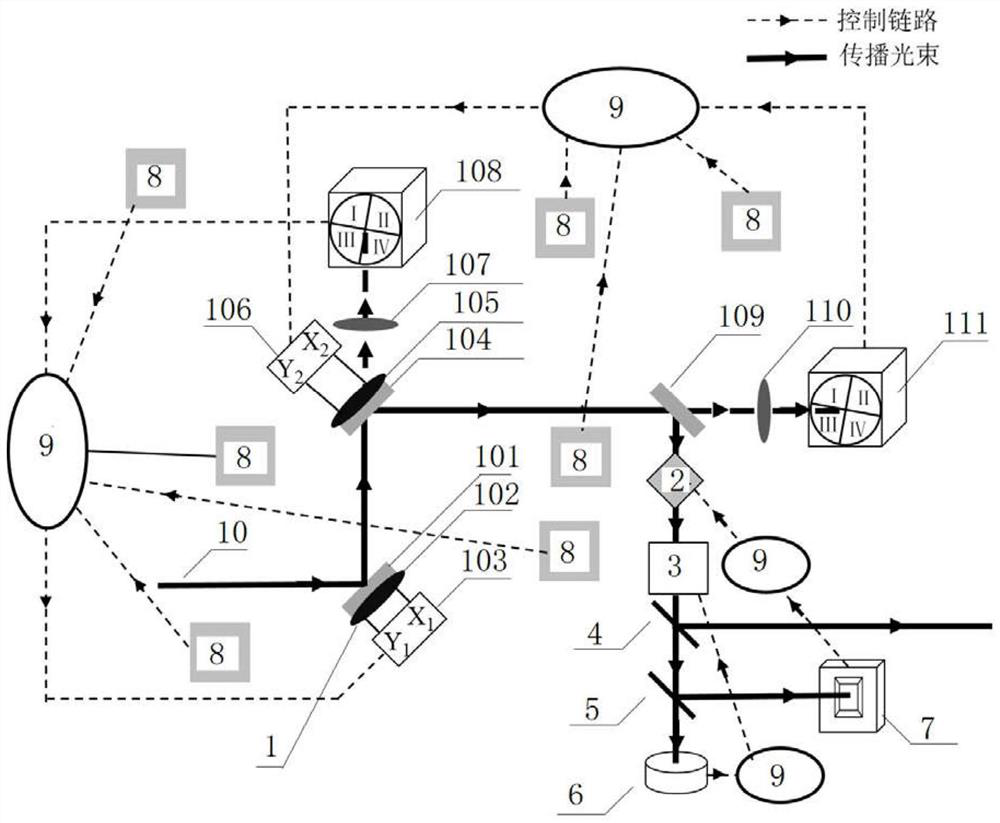

[0019] Such as figure 1 , The monitoring and feedback control system of laser output stability includes three key parts: laser steering device 1, beam detection and circuit control. The laser source emits laser light 10, which is output after being reflected by the first high reflection mirror 101, the second high reflection mirror 104, and the third high reflection mirror 109 of the laser steering device 1, wherein the first high reflection mirror 101 is installed on the first piezoelectric On the driving mirror base 102 , the second high reflection mirror 104 is installed on the second piezoelectric driving mirror base 105 . The laser light 10 passes through the second high reflection mirror 104 and converges on the detection target surface of the first four-quadrant diode 108 through the first focusing lens 107, and the laser light 10 passes through the third high reflection mirror 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com