Preparation method of high-calcium lactic acid bacteria fermented cucumber seed beverage

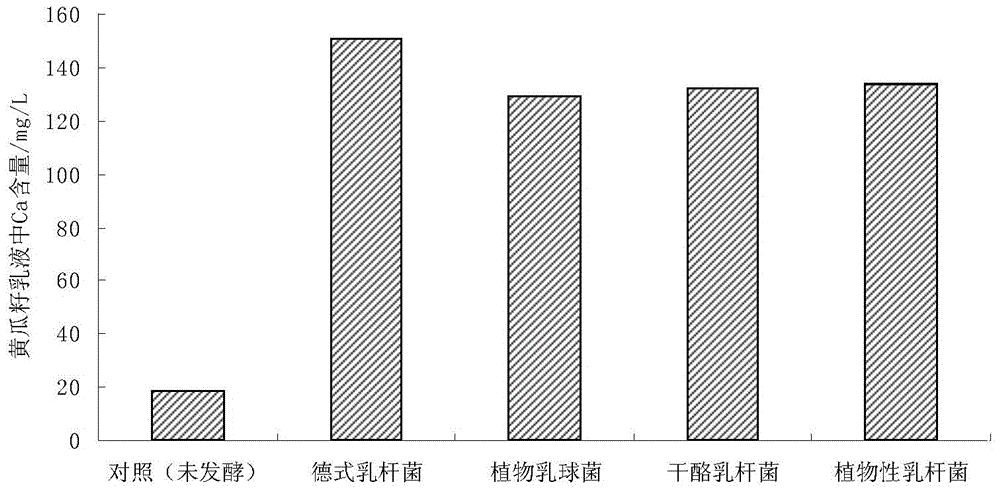

A technology of lactic acid bacteria fermentation and cucumber seeds, applied in the direction of lactobacillus, bacteria used in food preparation, and the function of food ingredients, etc., can solve the problems of few processed varieties, low calcium bioavailability, limited development level, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Select 20g of cucumber seeds and wash them for later use, add 1000mL of pure water (in order to eliminate the influence of water quality on the experimental results, pure water is used, but not limited to the use of pure water), 70g of sucrose is mixed and beaten with a beater, and then The colloid mill was homogenized for 3 times, and the obtained emulsion was divided into 200mL / bottles, covered, sterilized at 121°C for 15 minutes, and cooled for later use.

[0032] To prepare the fermented seed liquid of Lactobacillus germanus, first mix the MRS liquid medium and the cucumber seed emulsion in proportions of 10:0, 8:6, 5:5, 4:6, 2:8, and 0:10, and mix Lactobacillus germanus was transferred in turn, and the strains were acclimatized and cultured overnight at 34°C, so that the strains gradually adapted to grow in cucumber seed emulsion. The domesticated strains were placed in sterilized cucumber seed emulsion and cultured statically at 34°C, and the bacterial density was...

Embodiment 2

[0035] Choose 20g of cucumber seeds and wash for later use, add purified water (in order to eliminate the influence of water quality on the experimental results, the present invention adopts pure water, but not limited to the use of pure water) 1000mL, mix 70g of sucrose with a beater, and then use a colloid Grinding and homogenizing 3 times, the obtained emulsion was divided into 200mL / bottles, capped, sterilized at 121°C for 15 minutes, and cooled for later use.

[0036] To prepare the fermented seed liquid of Lactococcus plantarum, first mix the MRS liquid medium and cucumber seed emulsion in the ratio of 10:0, 8:6, 5:5, 4:6, 2:8, and 0:10, and mix the De Lactobacillus type was transferred in turn, and the strains were domesticated and cultured overnight at 30°C, so that the strains gradually adapted to grow in cucumber seed emulsion. The domesticated strains were placed in sterilized cucumber seed emulsion and cultured statically at 30°C, and the bacterial density was cont...

Embodiment 3

[0039] Choose 20g of cucumber seeds and wash for later use, add purified water (in order to eliminate the influence of water quality on the experimental results, the present invention adopts pure water, but not limited to the use of pure water) 1000mL, mix 70g of sucrose with a beater, and then use a colloid Grinding and homogenizing 3 times, the obtained emulsion was divided into 200mL / bottles, capped, sterilized at 121°C for 15 minutes, and cooled for later use.

[0040] To prepare the fermented seed liquid of Lactobacillus casei, first mix the MRS liquid medium and the cucumber seed emulsion at the ratio of 10:0, 8:6, 5:5, 4:6, 2:8, and 0:10, and mix the De Lactobacillus type was transferred in sequence, and the strains were domesticated and cultured overnight at 32°C, so that the strains gradually adapted to grow in cucumber seed emulsion. The acclimatized strains were placed in sterilized cucumber seed emulsion for static culture at 32°C, and the bacterial density was con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com