Machining device and workpiece machining method

A technology for mechanical processing and processed objects, which is applied in the direction of metal processing equipment, metal processing machinery parts, workpieces, etc., can solve the problems of reduced processing accuracy of processed objects, waste hindering measurement accuracy, and increased manufacturing costs, so as to maintain mechanical Processing accuracy, excellent machining accuracy, and the effect of improving the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

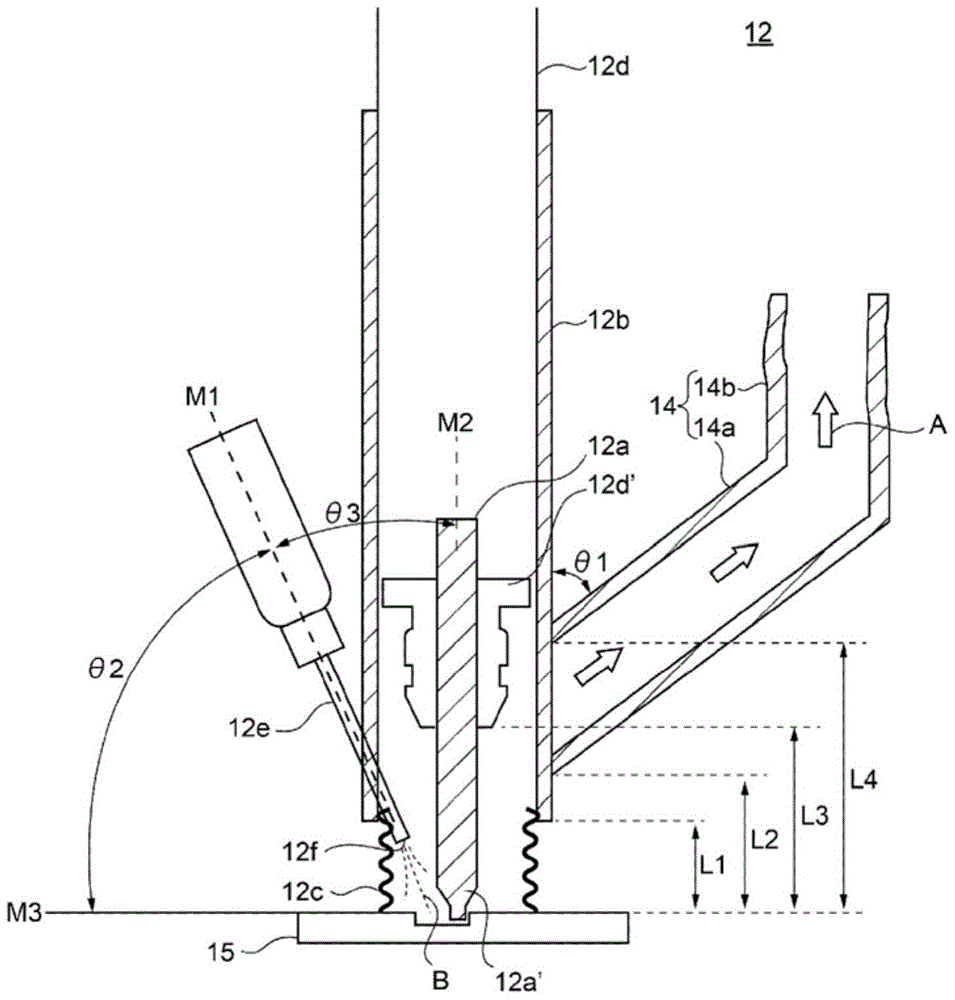

[0060] The first embodiment is as figure 1 As illustrated, it is a machining device 12 that performs predetermined machining on a workpiece 15 with a machine tool 12a housed inside a cylindrical object 12b. The machining device 12 is characterized in that the cylindrical The front end portion of the object 12b is provided with a splash-proof member 12c, which contacts the workpiece 15 without gaps during predetermined machining, and a conveying path 14 is provided on the side of the cylindrical object 12b, which is used for the predetermined machining. And the waste of the processed object 15 produced is sucked, and in the side of the cylinder 12b, an air blowing device 12e is provided at a position symmetrical to the position where the conveying path 14 is provided, and it is used to blow air to the machine tool. 12 at least the front end.

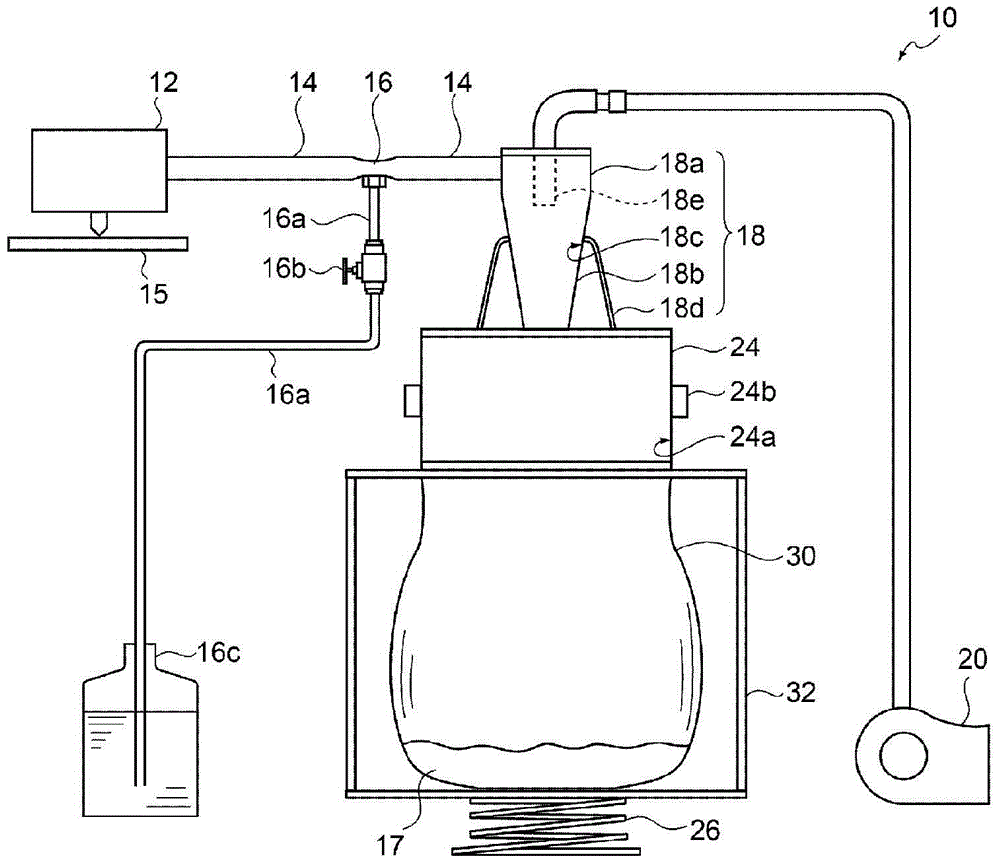

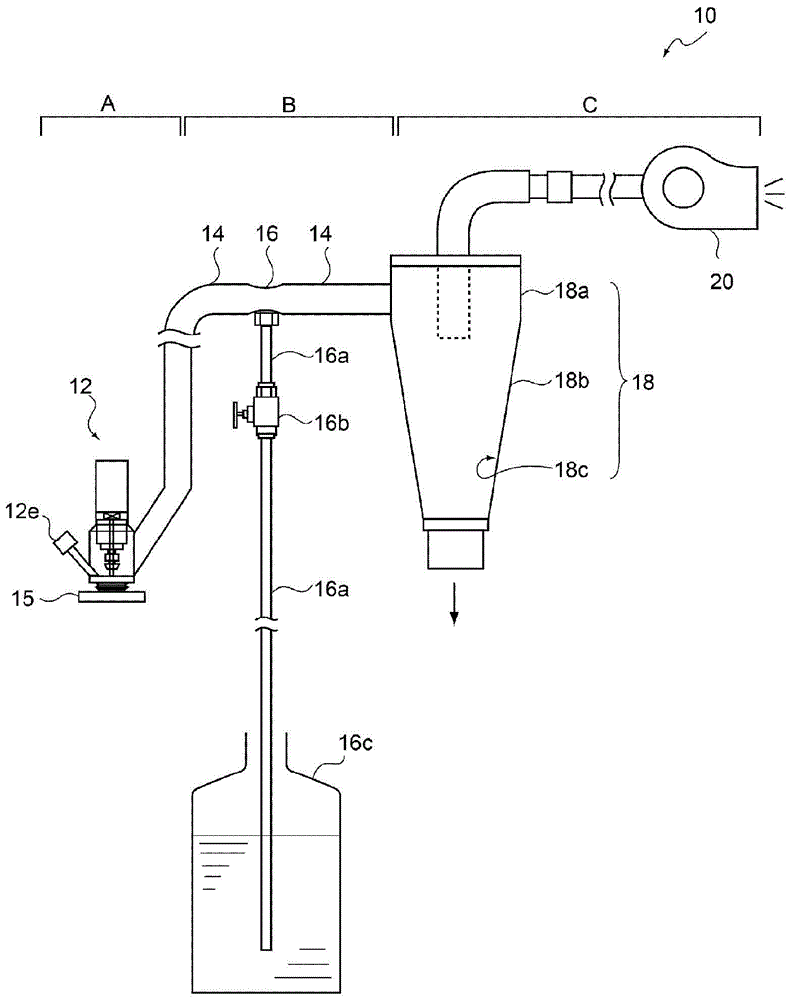

[0061] also, figure 1 is a schematic diagram of the machining device 12, figure 2 It is a schematic diagram showing the waste reco...

no. 2 approach

[0209]The second embodiment is a method of machining a workpiece using a machining device that performs predetermined machining on a workpiece with a machine tool housed inside a cylindrical object. The front end of the cylindrical object is provided with an anti-splash member, which is in contact with the workpiece without gaps during the specified machining, and a conveying path is provided on the side of the cylindrical object, which prevents the workpiece produced due to the specified machining. The waste of the processed object is sucked, and an air blowing port is provided at a symmetrical position on the side of the cylindrical object, which is used to blow air to at least the front end of the machine tool. The machining method of the processed object is characterized in that , including the following steps (1) to (2):

[0210] Step (1), using a machining device, blowing air to at least the front end of the machine tool through the air blowing port, and performing machi...

Embodiment 1

[0266] 1. Formation of fracture grooves for airbags

[0267] Prepared to include machining devices (machine tools: end mills) 12 Image 6 The shown airbag fracture groove forming device 100, the machining device (mechanical tool: end mill) 12 such as figure 1 as well as figure 2 As shown, a predetermined waste recycling device 18 including an antistatic treatment device 16 is provided.

[0268] At this time, the linear distance (L1) from the surface of the airbag base material (carbon-containing rigid polypropylene resin) with a thickness of 3 mm to the height position of the air outlet is 10 mm, and similarly, to the lower limit height position of the scattering prevention member The straight-line distance (L2) is 18mm. Similarly, the straight-line distance (L3) to the height position of the lower surface of the chuck of the workpiece is 20mm. Similarly, the straight-line distance (L4) to the upper limit height position of the component for preventing scattering is 30mm....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com