Install the radial support and axial preload structure of bearing motor rotor dynamic balance measurement

A technology of rotor dynamic balancing and radial support, which is used in electric components, manufacturing motor generators, adjusting/balancing rotors, etc., which can solve the problem that the unilateral preload cannot be transmitted, the processing technology is very demanding, and the bearing force is different. Large and other problems, to achieve the effect of reducing processing technology requirements, improving consistency and stability, and reducing runout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in conjunction with the accompanying drawings and embodiments.

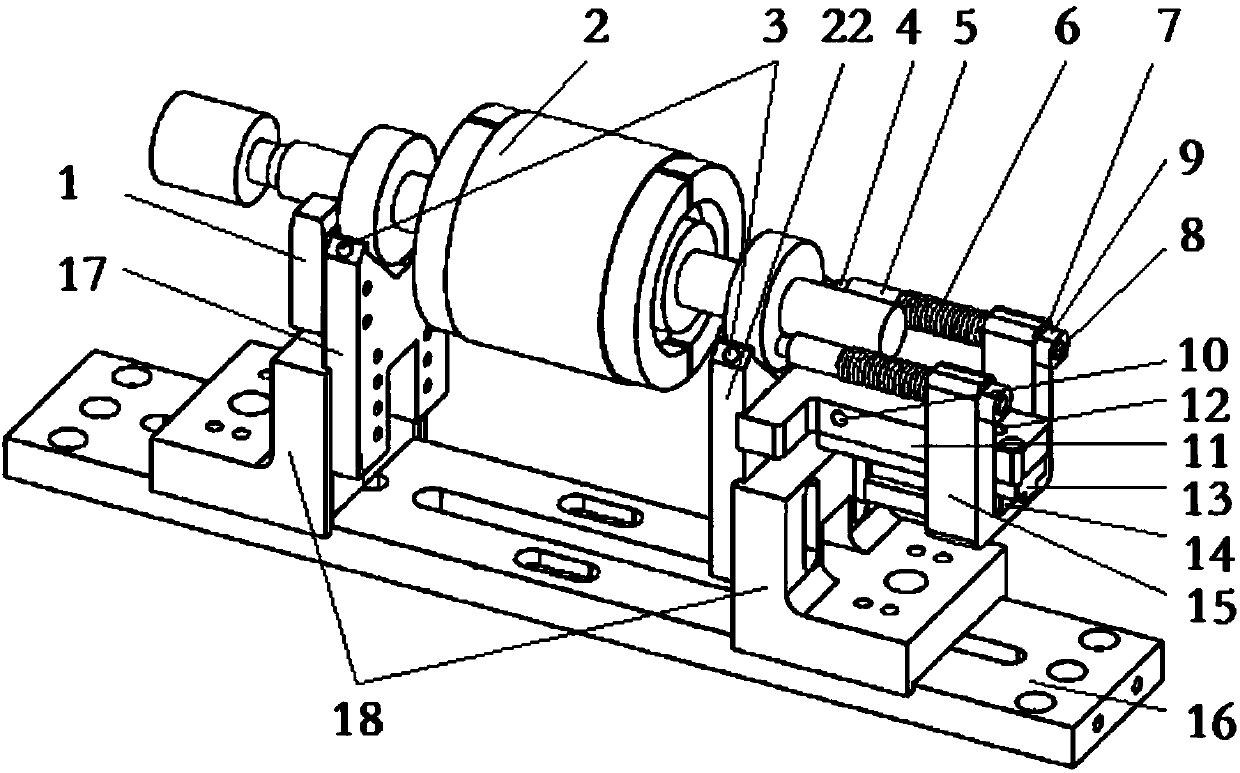

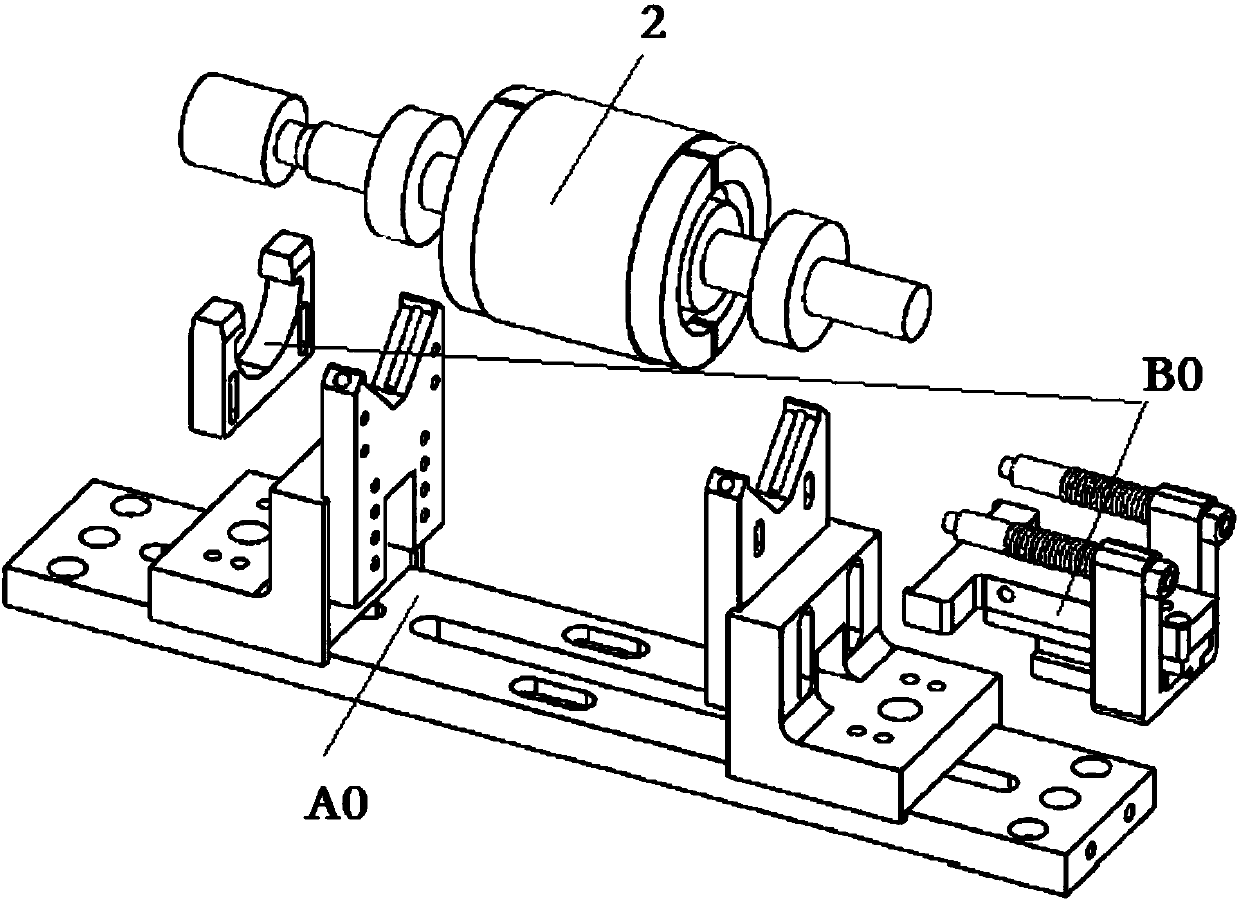

[0028] Such as figure 2 As shown, the present invention includes a rotor bearing radial support structure A0 and a rotor bearing axial preload structure B0, the motor rotor 2 is supported and installed on the rotor bearing radial support structure A0 for radial support, and is mounted on the rotor bearing radial The rotor bearing axial preloading structure B0 on the supporting structure A0 performs axial preloading.

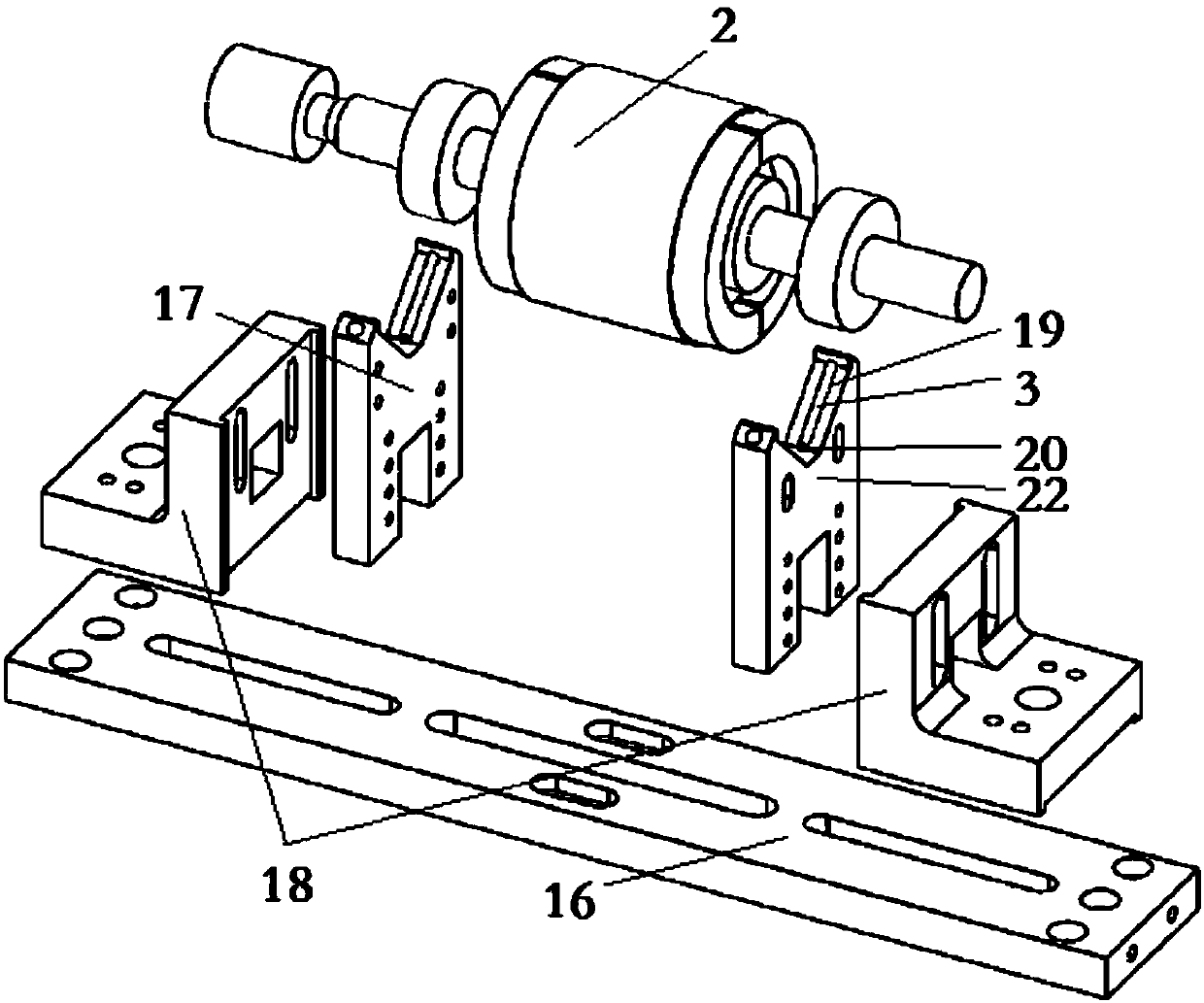

[0029] Such as figure 1 with image 3 As shown, the rotor bearing radial support structure A0 includes a tungsten steel rod 3, a radial support frame 17 on the blocking shaft side, a radial support frame 22 on the top shaft side, a radial support frame base 18 and a floating platform bottom plate 16, two radial The supporting frame base 18 is installed on both sides of the floating platform bottom plate 16 respectively, according to the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com