Electrothermic driven Fabry-perot light modulator

An electrothermal drive and modulator technology, applied in instruments, optics, nonlinear optics, etc., can solve the problems of low display performance of interferometric light modulators, easy pull-in phenomenon in driving, etc., and achieves elimination of pull-in phenomenon and large driving force. , the effect of reducing the requirements of the processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

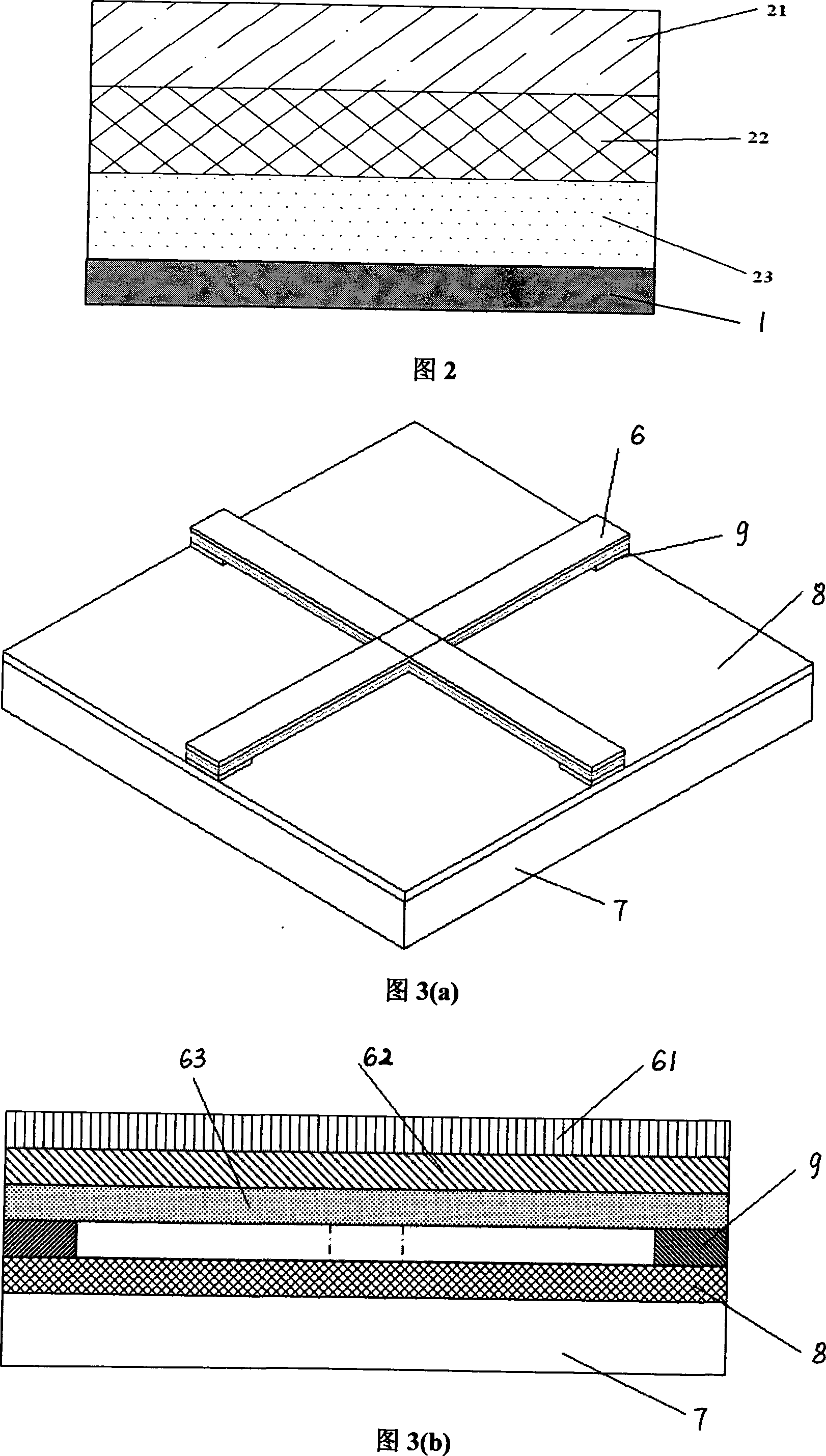

[0032] The structure and implementation of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0033] Figure 1(a) and Figure 1(b) show the structure of a single FAPO optical modulator, 1 is the glass substrate, 2 is the upper reflector, 3 is the FAPO cavity, 4 is the movable lower reflector, 5 is connected to the electric heater The supporting anchors of the drive beam and the lower reflector, 6 is an electrothermal drive component, and 7 is a silicon substrate. The cross-beam-shaped electrothermal driving part 6 is located on the silicon substrate 7, and the electrothermal driving part 6 is provided with a supporting anchor 5 to connect and support the movable lower reflector 4. The transparent glass substrate 1 is suspended and fixed on the silicon substrate 7 by bonding. On the base 7, the upper reflector 2 is attached to the lower surface of the glass substrate 1, and is opposite to the movable lower reflector 4, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com