Preparation method of high-stability amorphous manganous silicate

A high-stability, manganese silicate technology, applied in chemical instruments and methods, silicon compounds, non-metallic elements, etc., to achieve the effects of high production efficiency, easy cleaning and removal, and simple reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

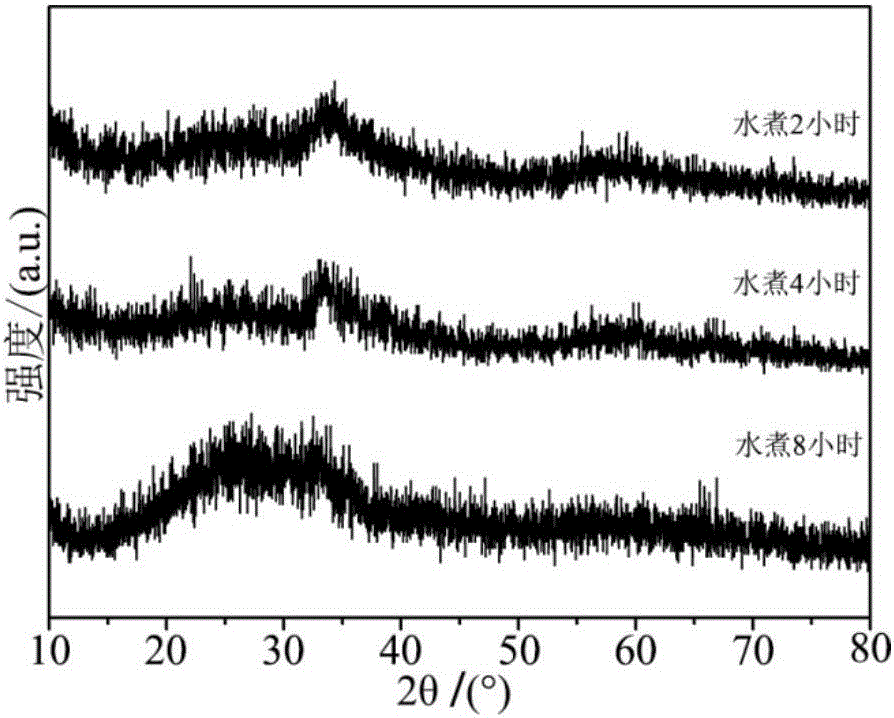

[0028] Amorphous manganese silicate is prepared by reacting sodium silicate and manganese chloride. Take 7.55g of manganese chloride and 10.85g of sodium silicate and dissolve them in 50mL of deionized water respectively. Under stirring, slowly add the manganese chloride solution into the sodium silicate solution, and mix well. The mixture was heated and boiled for 4 hours, cooled to room temperature, washed with deionized water three times, and then dried at 120°C to obtain 5.0 g of dark brown powder with a yield and purity close to 100%. According to X-ray diffraction pattern analysis (such as figure 1 Shown), the product is amorphous manganese silicate.

Embodiment 2

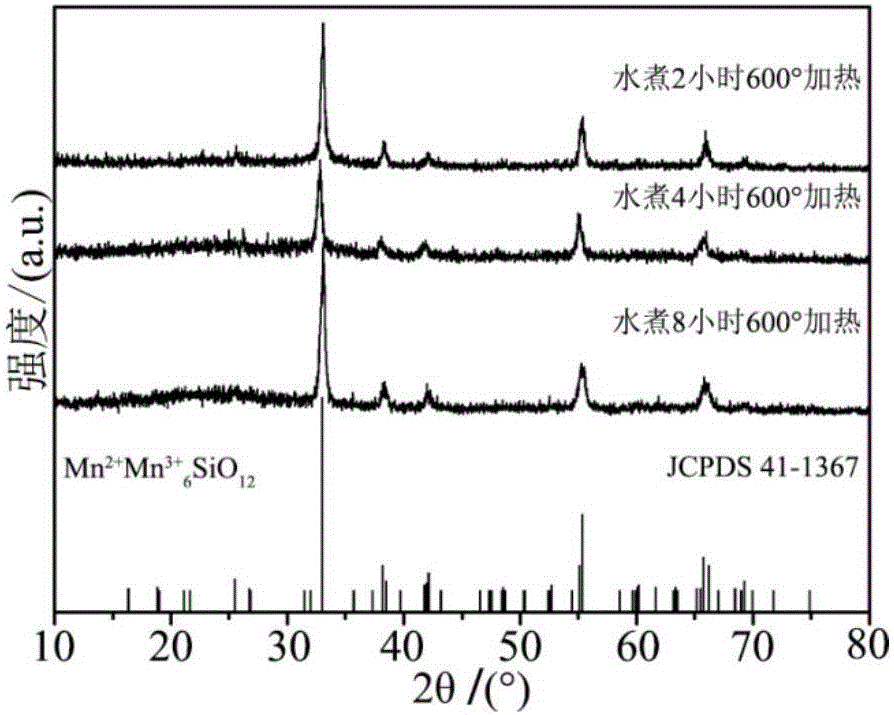

[0030] Weigh 1.0 g of the dark brown powder prepared in Example 1, heat in a tube furnace to 600° C. for 5 hours under a nitrogen atmosphere, and cool to room temperature to obtain a black powder. According to X-ray diffraction pattern analysis (such as figure 2 shown), the product is crystal phase composite manganese silicate Mn 2+ mn 3+ 6 SiO 12 (JCPDS41-1367).

Embodiment 3

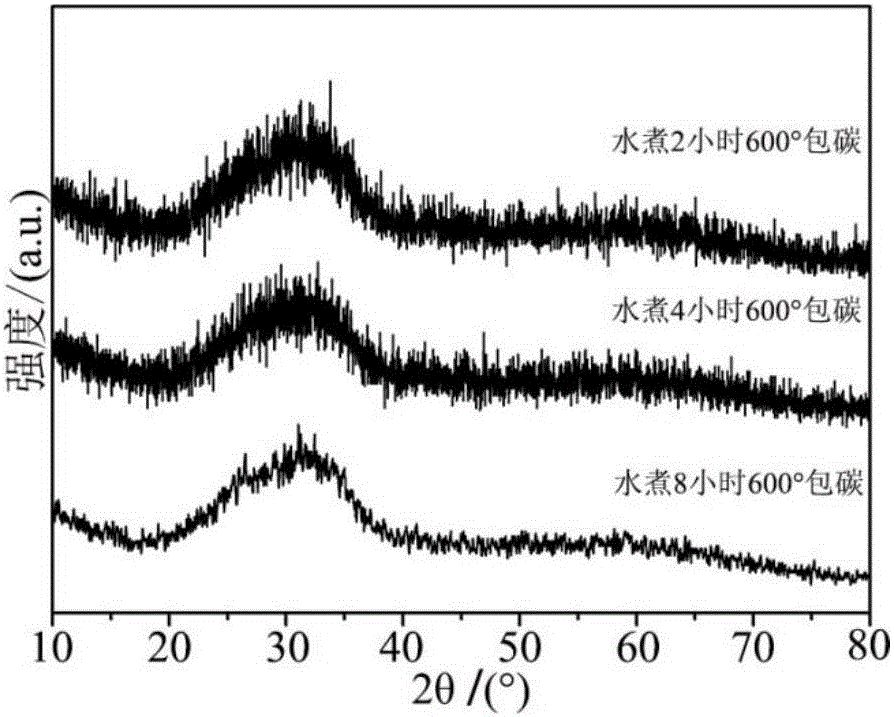

[0032] Weigh 1.5g of the dark brown powder prepared in Example 1 and 1.05g of glucose, add deionized water to dissolve the glucose, stir and mix evenly, put it into a tube furnace after drying at 120°C, and react in a nitrogen atmosphere at 600°C for 5 Hours later, it was naturally cooled to room temperature to obtain a black powder. According to X-ray diffraction pattern analysis (such as image 3 Shown), the product is amorphous manganese silicate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com