A temperature-controlled capillary electrophoresis interface for chemiluminescent reactions

A capillary electrophoresis and reaction capillary technology, applied in chemiluminescence/bioluminescence, analysis by chemical reaction of materials, etc., can solve the problems of temperature control without temperature control device, difficulty in fixing CL reagents, and poor reproducibility, etc. , to achieve the effect that the injection speed is not easy, the reproducibility is improved, and the effect is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

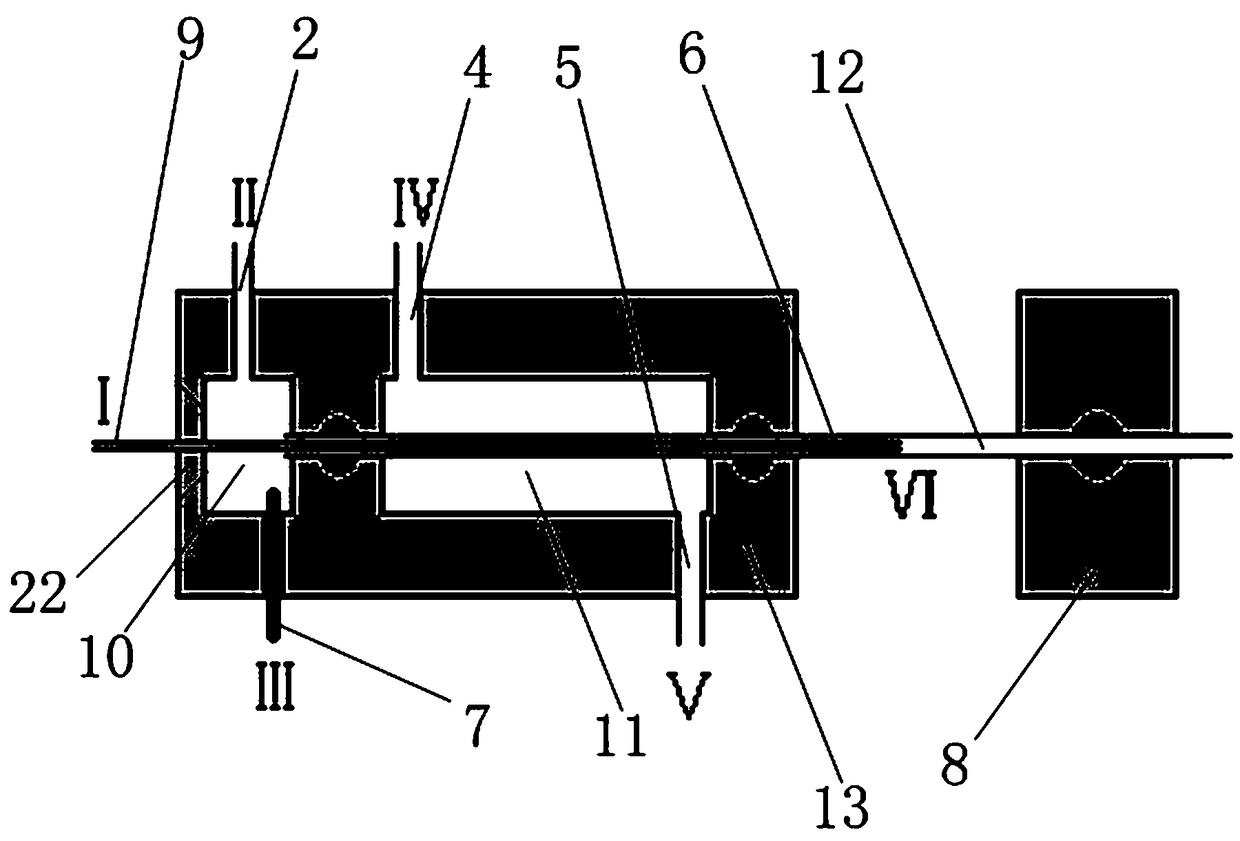

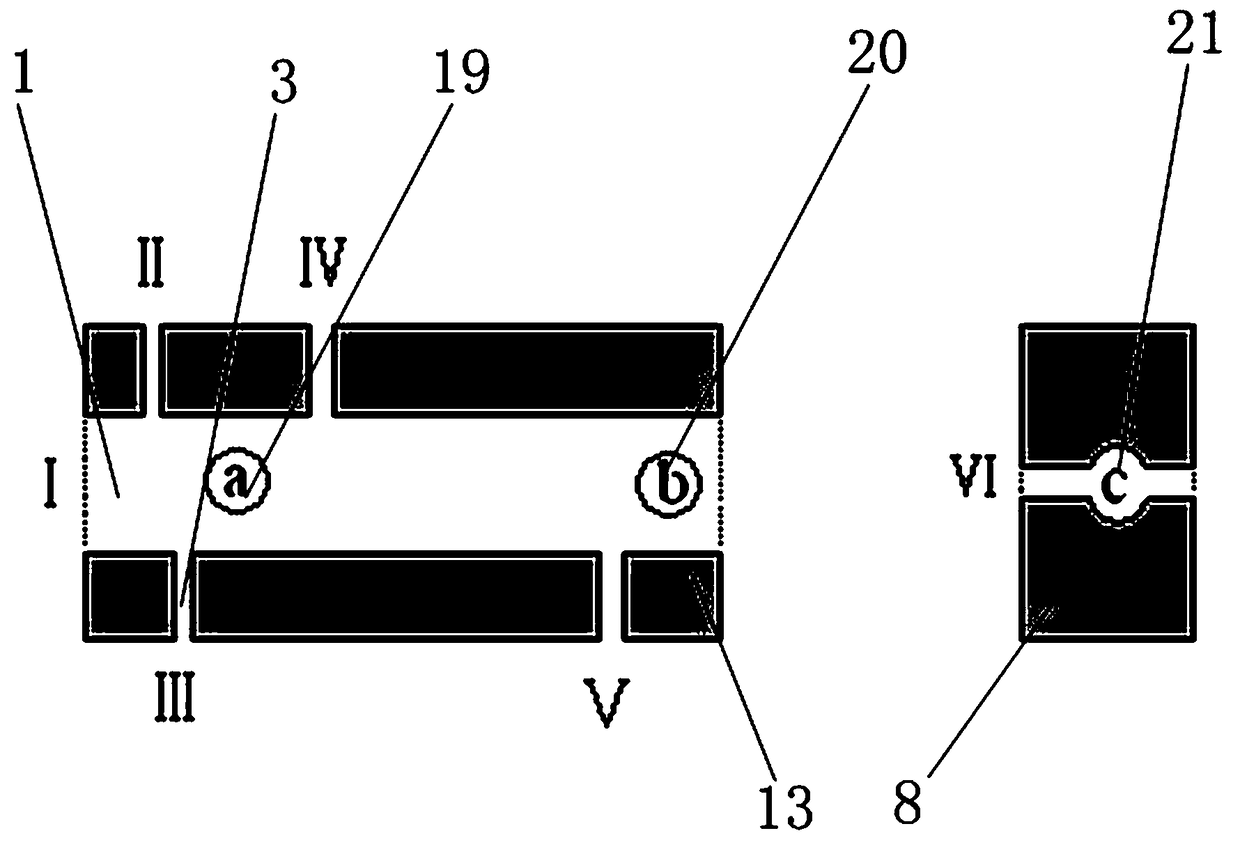

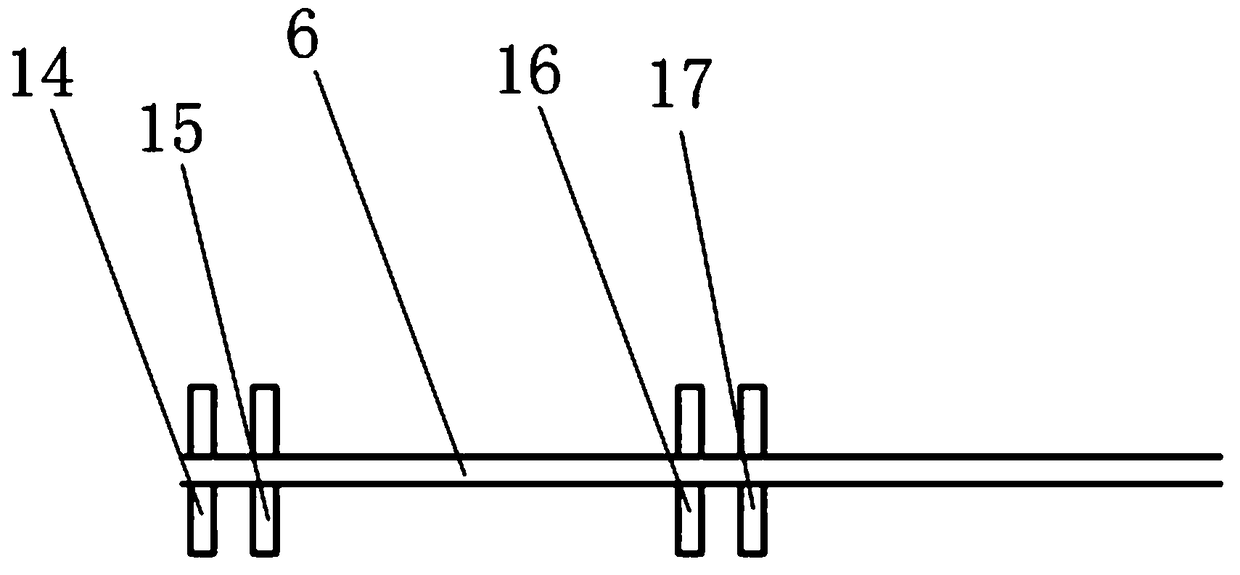

[0042] The operator activates the high-voltage electrode 7, and injects the electrophoresis buffer solution containing the component to be tested into the separation capillary 9 as the test substance. The outlet of the end of the capillary moves and enters the sleeve structure part of the capillary; the operator injects hot water into the water bath heating chamber, injects the luminescent reagent into the luminescent reagent chamber 10, and the luminescent reagent enters the reaction capillary 6 through the luminescent reagent chamber 10, and continues to move in the lumen Until the water bath heating chamber 11 is fully heated; the analyte is not heated because it moves in the separation capillary, and its electrophoretic separation operation is not affected, and the components to be analysed are fully separated under the action of the electric field. Since the outlet at the end of the separation capillary 9 is located in the reaction The inner cavity of the capillary, so whe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com