Method for producing quantum dot fluorescent anti-counterfeiting paper

The technology of quantum dots and anti-counterfeiting paper is applied in the field of preparation of quantum dot fluorescent anti-counterfeiting paper, which can solve the problems of complicated processes and achieve the effects of strong fluorescence intensity and stable fluorescence anti-counterfeiting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

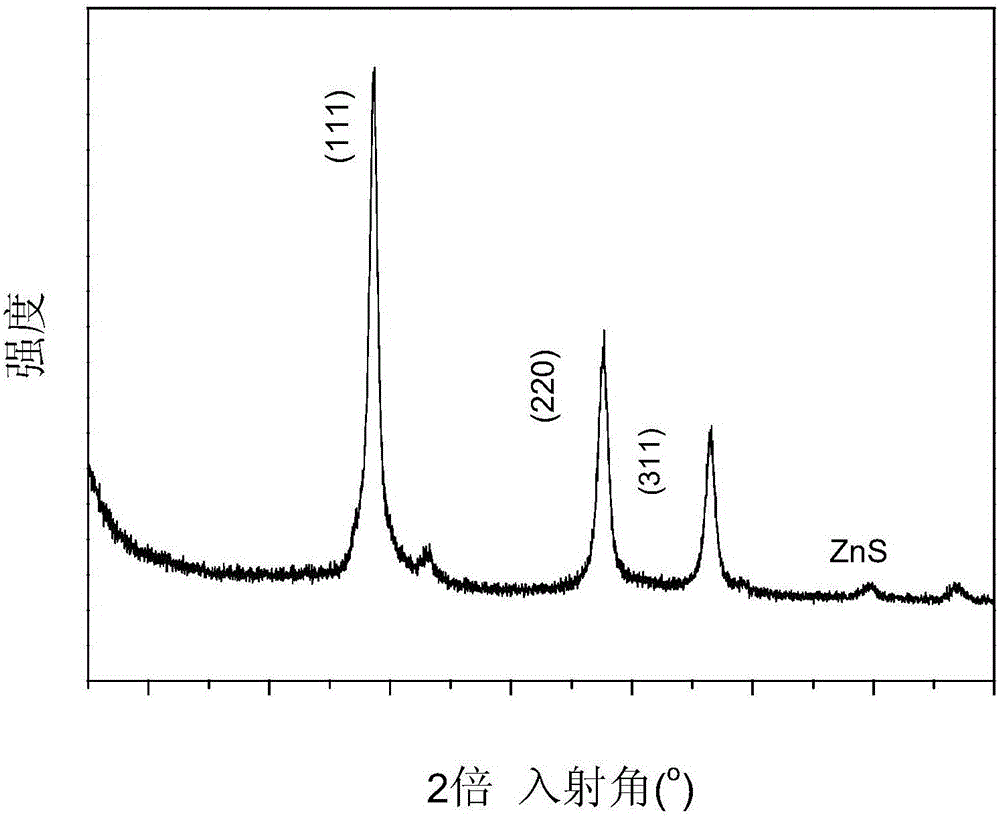

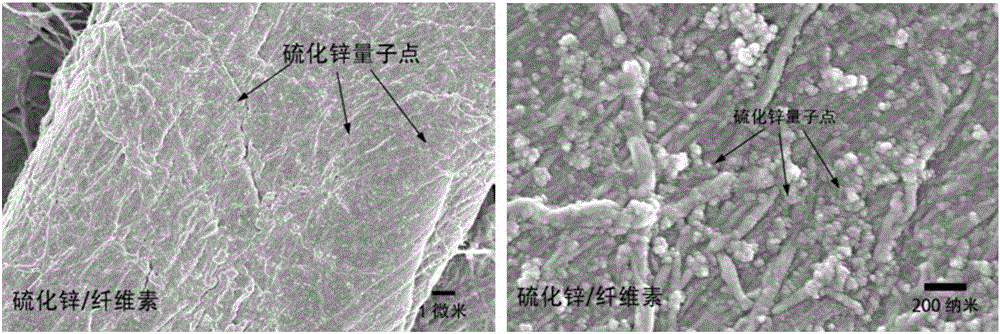

[0035] Taking the preparation of ZnS quantum dot fluorescent anti-counterfeiting paper as an example, the present invention is further described, and the steps are as follows:

[0036] (1) Add 1mmol sodium sulfide water / ethanol solution dropwise to 1mmoL zinc nitrate water / ethanol solution in magnetic stirring, stir at room temperature for 0-40min until the solution turns milky white, then add 0.03g / mL polyethylene Aqueous imine solution was stirred for a period of time to obtain a reaction mixed suspension.

[0037] (2) Invert the mixed suspension obtained in step (1) into an 80 mL tetrafluoroethylene stainless steel autoclave, and immerse the routine quantitative filter paper in the laboratory into the mixed solution. Put the autoclave in an oil bath at 180°C for 10 hours.

[0038] (3) After the reaction is over, the autoclave is naturally cooled to room temperature, and the product obtained is a slightly yellow composite filter paper, which is washed several times with dei...

Embodiment 2

[0041] Taking the preparation of ZnS quantum dot fluorescent anti-counterfeiting paper as an example, the present invention is further described, and the steps are as follows:

[0042] (1) Add 1mmol sodium sulfide water / ethanol solution dropwise to 1mmoL zinc nitrate water / ethanol solution in magnetic stirring, stir at room temperature for 0-40min until the solution turns milky white, then add 0.03g / mL polyethylene Aqueous imine solution was stirred for a period of time to obtain a reaction mixture suspension.

[0043] (2) Invert the mixed suspension obtained in step (1) into an 80 mL tetrafluoroethylene stainless steel autoclave, and immerse the routine quantitative filter paper in the laboratory into the mixed solution. Put the autoclave in an oil bath at 100°C for 24h.

[0044] (3) After the reaction is over, the autoclave is naturally cooled to room temperature, and the product obtained is a slightly yellow composite filter paper, which is washed several times with deioni...

Embodiment 3

[0047] Taking the preparation of ZnS quantum dot fluorescent anti-counterfeiting paper as an example, the present invention is further described, and the steps are as follows:

[0048] (1) Add 1mmol sodium sulfide water / ethanol solution dropwise to 1mmoL zinc nitrate water / ethanol solution in magnetic stirring, stir at room temperature for 0-40min until the solution turns milky white, then add 0.03g / mL polyethylene Aqueous imine solution was stirred for a period of time to obtain a reaction mixture suspension.

[0049] (2) Invert the mixed suspension obtained in step (1) into an 80 mL tetrafluoroethylene stainless steel autoclave, and immerse the routine quantitative filter paper in the laboratory into the mixed solution. Put the autoclave in an oil bath at 200°C for 8h.

[0050] (3) After the reaction is over, the autoclave is naturally cooled to room temperature, and the product obtained is a slightly yellow composite filter paper, which is washed several times with deioniz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com