A kind of air bubble spinning device

A technology of bubble spinning and foaming device, applied in the field of spinning, can solve problems such as easy blockage of needles, waste of raw materials, unstable spinning process, etc., achieve uniform micro-nano fibers, increase production, and simple and easy-to-control spinning process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

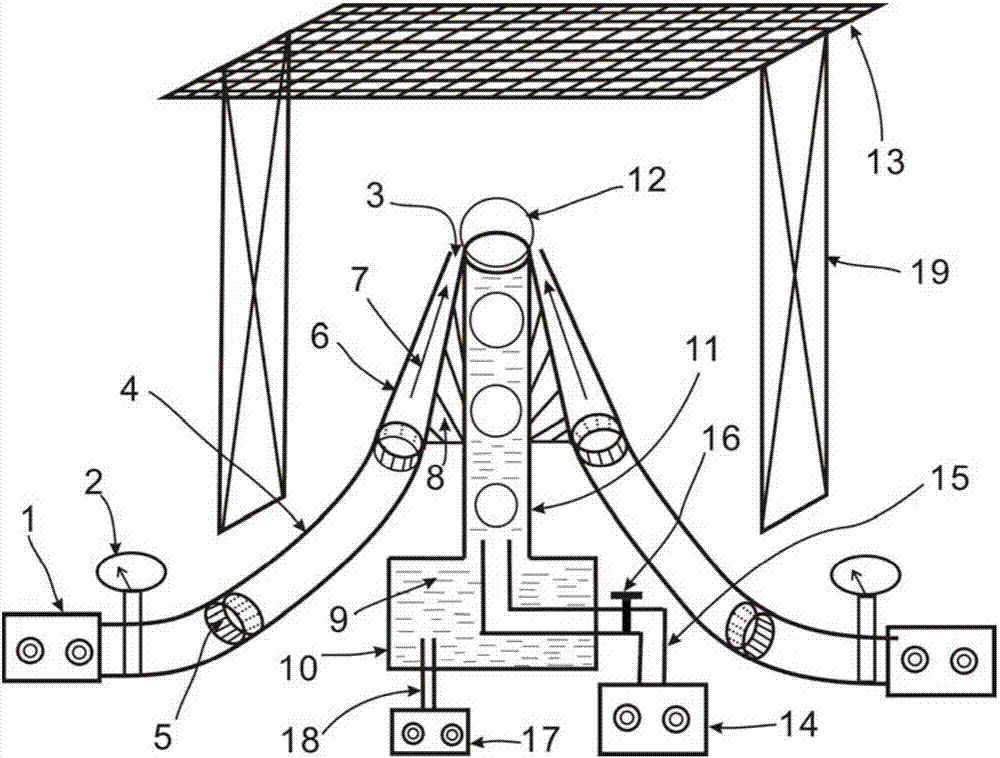

[0025] There are many problems in the traditional electrospinning technology, such as: the spinnability of high-concentration and high-viscosity solutions is poor, the solution containing particles is easy to block the needle, and the yield of preparing micro-nano fibers is low. Mass production of nanofibers. At the same time, the high-voltage electrostatic hazard is very serious, which brings great inconvenience to the experimental operation and is a great obstacle to expanding the production of micro-nano fibers.

[0026] Aiming at the deficiencies in the prior art, the present invention provides an air bubble spinning device, which realizes spinning without static electricity, improves production efficiency, realizes safe production, and realizes mass production of fibers to a certain extent. At the same time, a micro-nano fiber assembly with a fiber yarn structure can also be obtained.

[0027] The technical solutions of the present invention will be clearly and completel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com