Cored wire for preparing nickel-based high-aluminum coating and coating preparation method of cored wire

A powder core wire material, nickel-based technology, applied in the preparation of coating, powder core wire material and its coating, powder core wire material field, can solve the problem that Ti element is expensive, high manufacturing cost, and cannot be widely used To solve the problems of ground application and other issues, achieve the effect of high hardness, low cost and small thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

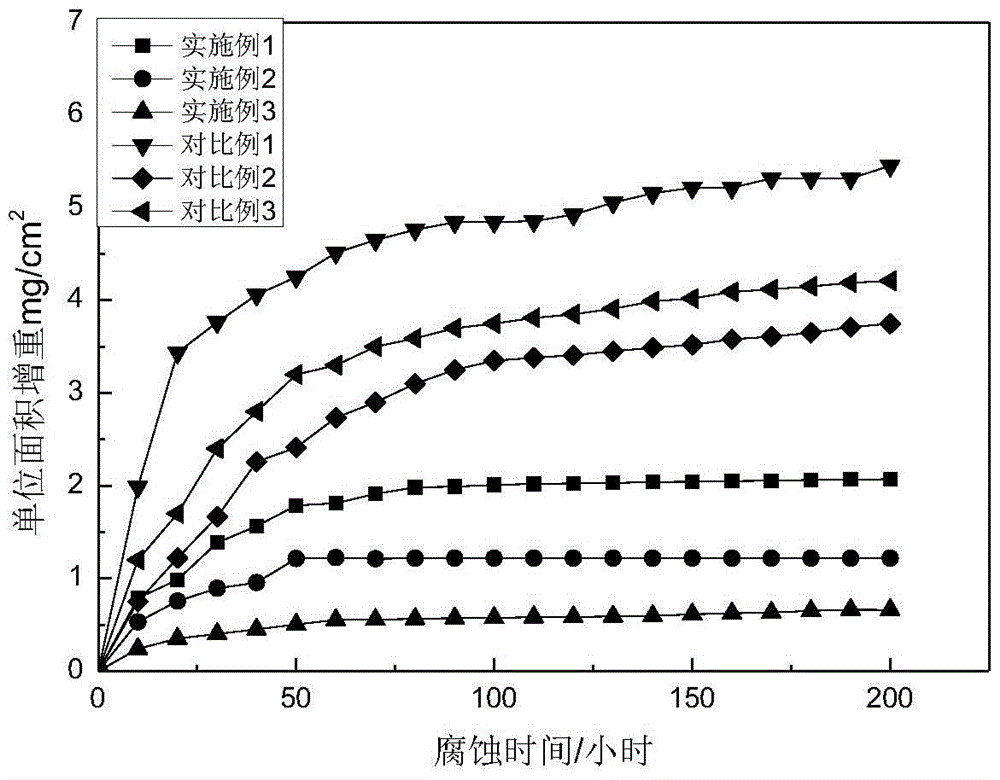

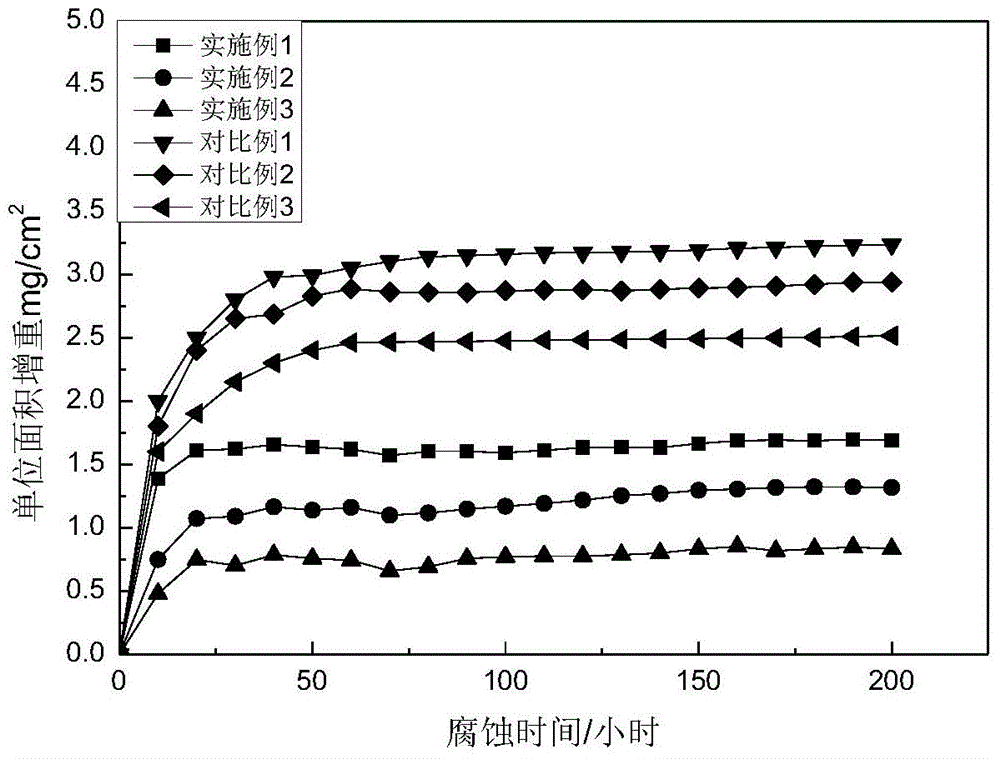

Embodiment 1

[0040] The mass percentage of powder core wire drug core composition is: Cr: 25%, Al: 4%, B: 3%, Si: 5%, Ni: balance. Rolled powder core wire, filling rate: 26%. Spraying parameters used for coating preparation: voltage 28-30V, current 160-180A, spraying distance 200mm, compressed air pressure 0.5-0.6MPa.

Embodiment 2

[0042]The mass percentage of powder core silk drug core composition is: Cr: 20%, Al: 7%, B: 5%, Si: 3%, Ni: balance. Rolled powder core wire, filling rate: 26%. Spraying parameters used for coating preparation: voltage 30-32V, current 160-180A, spraying distance 210mm, compressed air pressure 0.5-0.6MPa.

Embodiment 3

[0044] The mass percentage of powder core wire material is: Cr: 15%, Al: 9%, B: 4%, Si: 4%, Ni: balance. Rolled powder core wire, filling rate: 26%. Spraying parameters used for coating preparation: voltage 28-30V, current 180-200A, spraying distance 200mm, compressed air pressure 0.5-0.6MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com