Method for purifying troxerutin from troxerutin industrial decoction dreg

A kind of dregs, industrial technology, applied in the field of purification and extraction of troxerutin, can solve the problems of increased production costs, non-compliance, and difficulty in recycling dregs, and achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

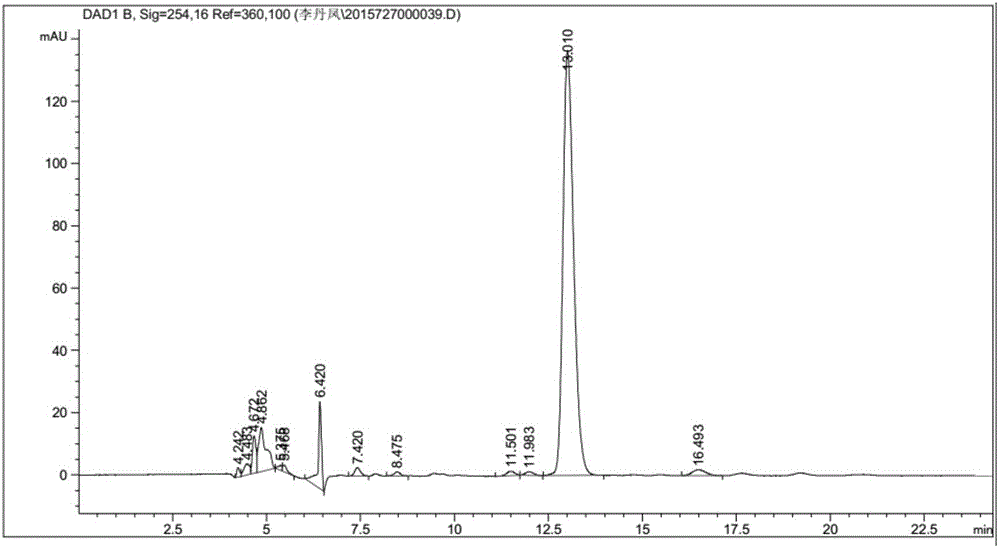

Embodiment 1

[0021] Take 1g of troxerutin industrial dregs in a 25mL beaker, add 10ml of distilled water to dissolve, let stand for 12h and then filter, discard the filter residue, and keep the filtrate for later use. Take 50g of hydroxypropyl dextran gel LH-20, soak it in 500ml of distilled water overnight, remove the floating matter, pour it into a glass column (diameter-to-length ratio is 1:20, column volume 50mL), wait for the soaking liquid to flow to the liquid surface, add troxerutin dregs filtrate, wait for the filtrate to flow to the liquid surface, then wash the stigma with 1ml of distilled water, add 500ml of distilled water to elute after the stigma is cleaned, start to collect after elution of 100ml, collect 50ml; After being concentrated and dried under pressure, the troxerutin was detected by HPLC up to 85%, and the recovery rate was 88%, which met the oral liquid specification.

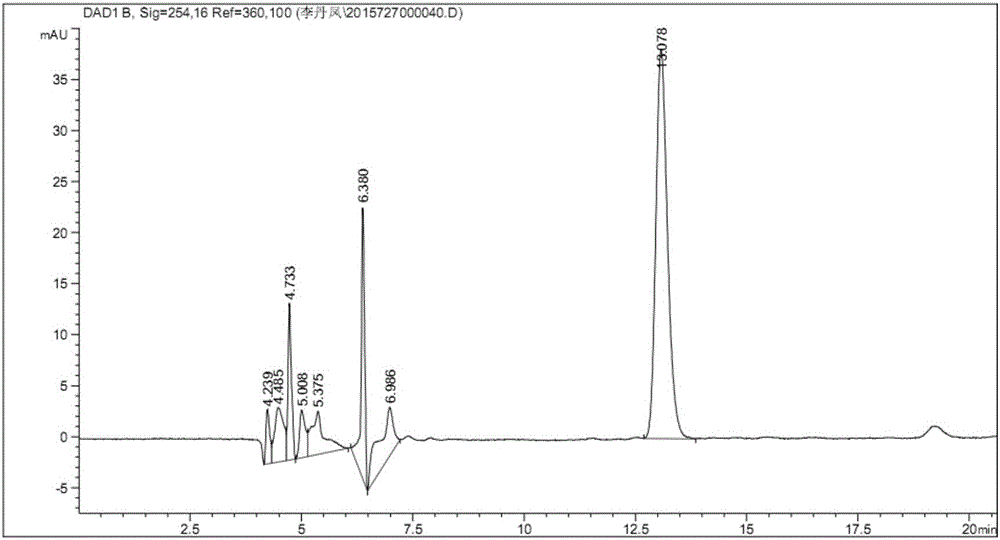

Embodiment 2

[0023] Take 1g of troxerutin industrial dregs in a 25mL beaker, add 10ml of distilled water to dissolve, let stand for 12h and then filter, discard the filter residue, and keep the filtrate for later use. Take 50g of hydroxypropyl dextran gel LH-20, soak it overnight with 500ml of methanol-water (30% methanol, volume ratio) solution, remove the floating matter, and pour it into a glass column (the ratio of diameter to length is 1:20, Column volume 50mL), when the soaking liquid flows to the liquid surface, add troxerutin dregs filtrate, wait for the filtrate to flow to the liquid surface, then wash the column head with 1ml distilled water, add 500ml methanol-water (30% methanol ) solution elution, start to collect after elution 100ml, collect 50ml; After 50ml collection liquid is concentrated and dried under reduced pressure, detect through HPLC, troxerutin content is 82.5%, and recovery rate is 80%, meets oral liquid specification.

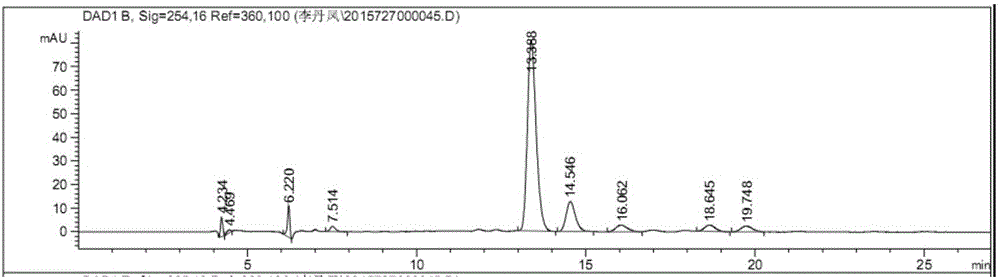

Embodiment 3

[0025] Take 1g of troxerutin industrial dregs in a 25mL beaker, add 10ml of distilled water to dissolve, let stand for 12h and then filter, discard the filter residue, and keep the filtrate for later use. Take 50g of hydroxypropyl dextran gel LH-20, soak it overnight with 500ml of methanol-water (60% methanol, volume ratio) solution, remove the floating matter, and pour it into a glass column (diameter-to-length ratio of 1:20, Column volume 50mL), when the soaking liquid flows to the liquid surface, add troxerutin dregs filtrate, wait for the filtrate to flow to the liquid surface, then wash the column head with 1ml distilled water, add 500ml methanol-water (60% methanol ) solution elution, start to collect after elution 100ml, collect 50ml; After 50ml collection liquid is concentrated and dried under reduced pressure, detect by HPLC, troxerutin content is 81%, and recovery rate is 82%, meets oral liquid specification.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com