Resourceful treatment method for petroleum coke burning dust

A treatment method and technology of petroleum coke, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of soil and groundwater environmental pollution, complex dust composition, difficult comprehensive reuse, etc., to reduce Environmental pollution, realization of industrial application, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

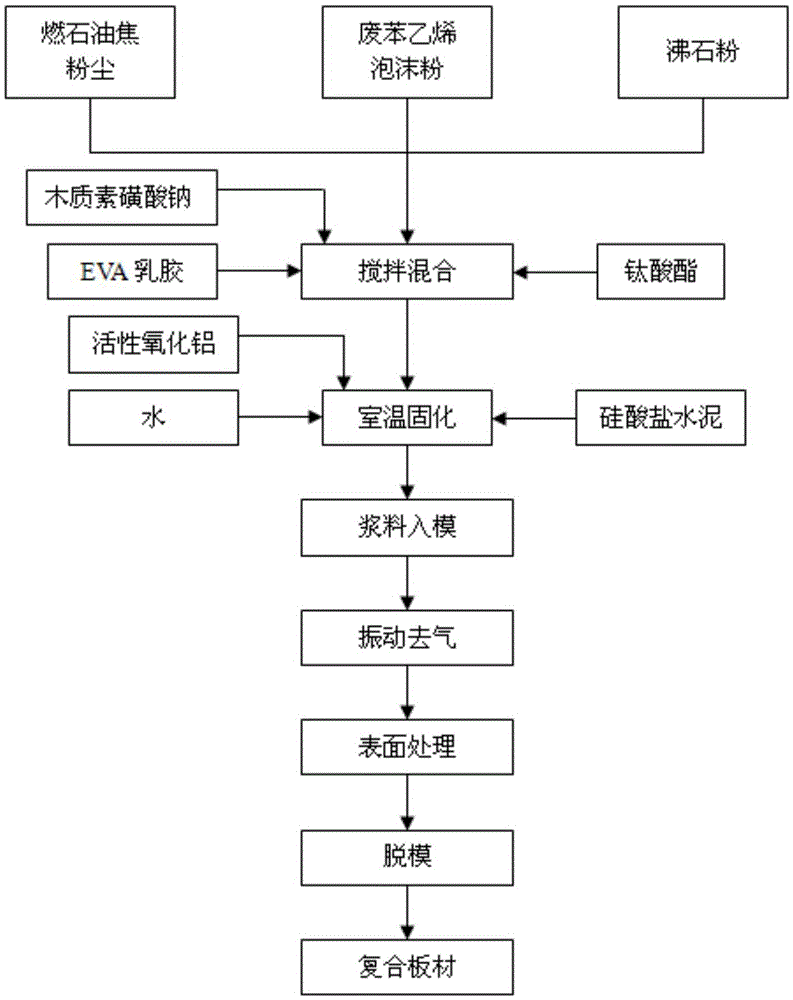

[0034] Prepare fuel oil coke powder with a mass fraction of 80%, waste styrene foam powder with a mass fraction of 10% in a particle size range of 5 to 10mm, and zeolite powder with a mass percentage of 10% in a particle size range of 1 to 5mm, in a mixer Mix well in the medium, add titanate accounting for 0.1% of the weight of the mixed material, add EVA latex accounting for 0.5% of the weight of the mixed material, add sodium lignosulfonate accounting for 0.1% of the weight of the mixed material and stir and mix evenly; the treated mixed material Fully mix 85% by mass with cement powder, add activated alumina accounting for 0.1% of the weight of the mixed material, and then add an appropriate amount of water to stir and mix to form a slurry; inject the slurry into the trial mold, and cast it into shape; inject the slurry The test mold after filling was placed on a vibrating machine to vibrate for 5 minutes to remove air bubbles and accelerate the hydrothermal synthesis reacti...

Embodiment 2

[0036] Prepare fuel oil coke powder with a mass fraction of 60%, waste styrene foam powder with a mass fraction of 20% in a particle size range of 5 to 10 mm, and zeolite powder with a mass percentage of 20% in a particle size range of 1 to 5 mm. Mix fully in the medium, add titanate accounting for 0.5% of the weight of the mixture, add EVA latex accounting for 0.1% of the weight of the mixture, add sodium lignosulfonate accounting for 0.5% of the weight of the mixture and stir and mix evenly; the treated mixture Fully mix with cement powder according to the mass percentage of 100%, add activated alumina accounting for 1% of the weight of the mixed material, and then add an appropriate amount of water to stir and mix to form a slurry; inject the slurry into the test mold and cast it into shape; inject the slurry The test mold after filling was placed on a vibrating machine to vibrate for 5 minutes to remove air bubbles and accelerate the hydrothermal synthesis reaction of the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com