Waterproof mortar taking inorganic minerals as main filler

A waterproof mortar and inorganic mineral technology, applied in the field of building decoration materials, can solve the problems of late strength, complicated operation methods, poor weather resistance, etc., and achieve the effect of good strength growth, high overall density, and improved internal performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

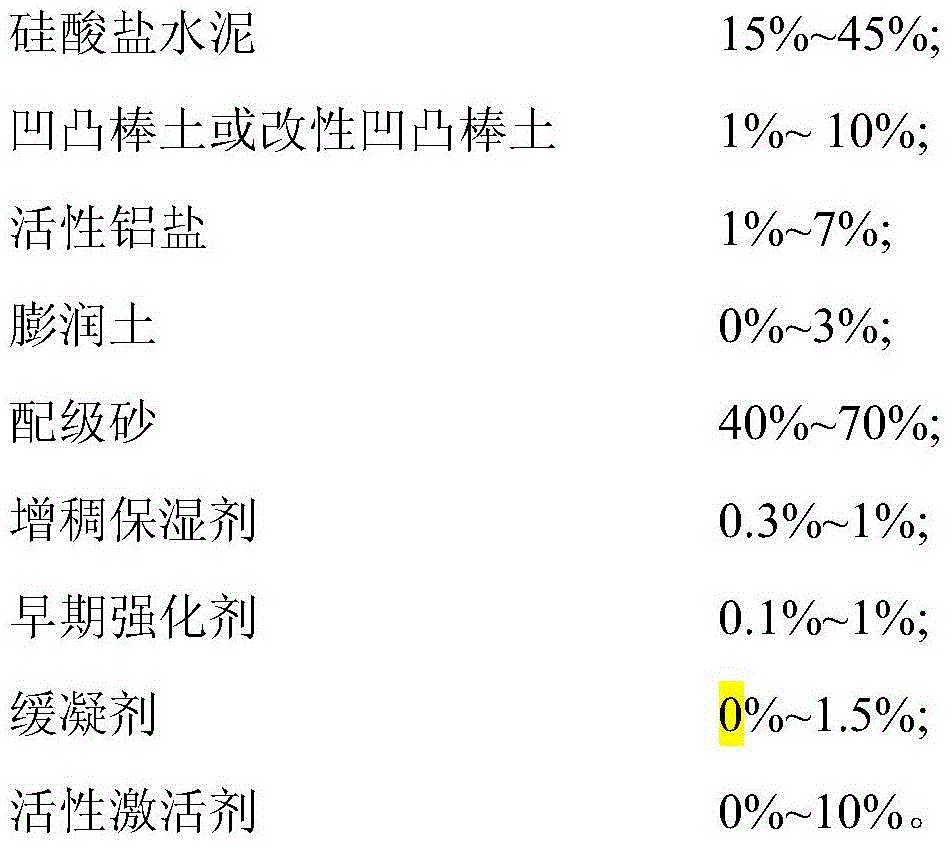

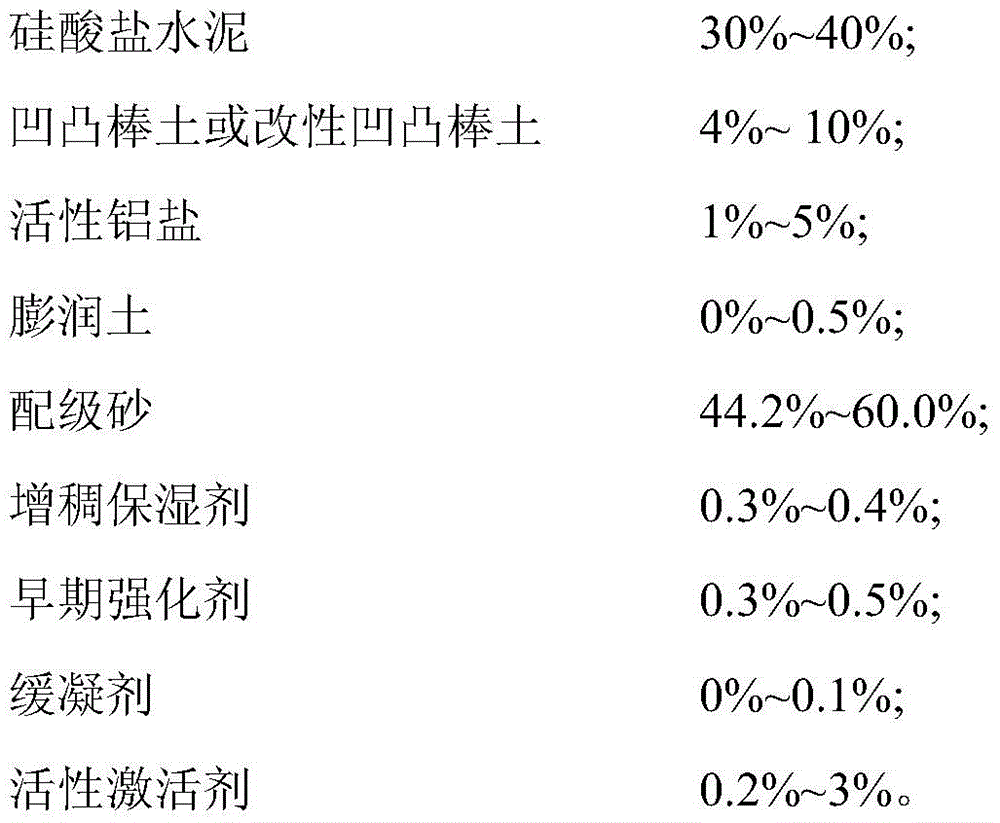

Method used

Image

Examples

Embodiment 1

[0046] The raw material of the waterproof mortar component with inorganic minerals as the main filler described in Example 1 of the present invention is:

[0047] 300 parts of ordinary Portland cement, 587 parts of graded quartz sand, 40 parts of attapulgite, 5 parts of bentonite, 3 parts of early strengthening agent calcium formate, 10 parts of active aluminum salt aluminum sulfate, thickening and moisturizing agent hydroxymethyl cellulose 3 parts, 1 part of retarder sodium citrate, 1 part of antifreeze agent magnesium chloride, 30 parts of silica powder, 20 parts of active activator sodium silicate, and water 240-350. The grading situation of the quartz sand is as follows: coarse-grained quartz sand is passed through a 40-80 mesh sieve, and fine-grained quartz sand is passed through 80-120 mesh, and the ratio of the coarse sand to the fine sand is 2:1.

[0048] Put the above-mentioned component materials in a mixing tank and mix them evenly for 20 minutes. According to the rated ...

Embodiment 2

[0050] The raw material of the waterproof mortar component with inorganic minerals as the main filler described in Example 2 of the present invention is:

[0051] 350 parts of ordinary Portland cement, 600 parts of graded quartz sand, 10 parts of attapulgite, 3 parts of thickening and moisturizing agent hydroxypropyl methylcellulose, 30 parts of active aluminum salt aluminum sulfate, 1 part of retarder tartaric acid, 3 parts of Nai-series water reducing agent, 3 parts of early intensifier calcium formate, with 180-280 parts of water. The grading situation of the quartz sand is as follows: coarse-grained quartz sand is passed through a 40-80 mesh sieve, and fine-grained quartz sand is passed through 80-120 mesh, and the ratio of the coarse sand to the fine sand is 2:1.

[0052] Put the above-mentioned component materials in a mixing tank and mix them evenly for 20 minutes. According to the rated weight, pack them into a packaging bag with an inner film. The relative humidity of the ...

Embodiment 3

[0054] The raw material of the waterproof mortar component with inorganic minerals as the main filler described in Example 3 of the present invention is:

[0055] Ordinary Portland cement 380 parts, graded quartz sand 442, attapulgite 100, thickening and moisturizing agent hydroxypropyl methylcellulose 3 parts, silicon powder 20 parts, active aluminum salt aluminum potassium sulfate 50 parts, early strengthening agent 5 parts of sodium carbonate. The grading situation of the quartz sand is as follows: coarse-grained quartz sand is passed through a 40-80 mesh sieve, and fine-grained quartz sand is passed through 80-120 mesh, and the ratio of the coarse sand to the fine sand is 2:1.

[0056] Put the above-mentioned component materials in a mixing tank and mix them evenly for 20 minutes. According to the rated weight, pack them into a packaging bag with an inner film. The relative humidity of the environment is less than 80%. The inner film is sealed and the outside is sealed to avoid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com