Sewage oxidation treatment device

An oxidation treatment and sewage technology, applied in the field of water treatment, can solve the problems of large equipment investment, complicated operation and high energy consumption, and achieve the effect of improving oxidation efficiency, promoting hydraulic cavitation and disintegrating pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

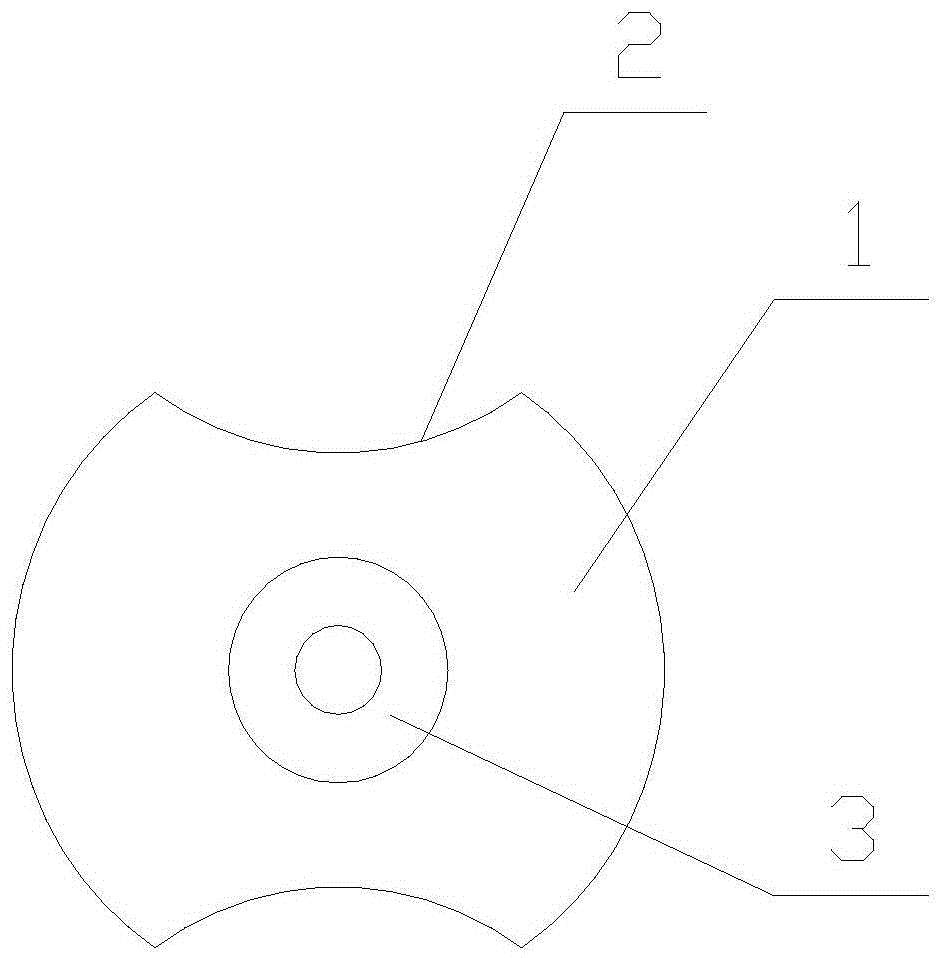

[0036] Such as Figure 1-6 As shown, a sewage oxidation treatment device of the present invention includes a rotating body 1 provided with an arc-shaped groove 2, and the center of the rotating body 1 is provided with a connecting hole 3 connected to the rotating mechanism; the arc-shaped groove 2 has at least Two are evenly arranged on the rotating body 1 at equal intervals. The rotating body 1 is a cylindrical structure, and the upper bottom surface and the lower bottom surface of the rotating body 1 are provided with connecting holes 3; the rotating mechanism is a motor, and the connection between the motor output shaft 7 and the upper bottom surface of the rotating body 1 Holes 3 are connected.

[0037] The rotating body 1 described in this embodiment is provided with two arc-shaped grooves 2, the two arc-shaped grooves 2 are arranged symmetrically, and the two arc-shaped grooves 2 are arranged on the side of the rotating body 1 from top to bottom; The arc centers of the...

Embodiment 2

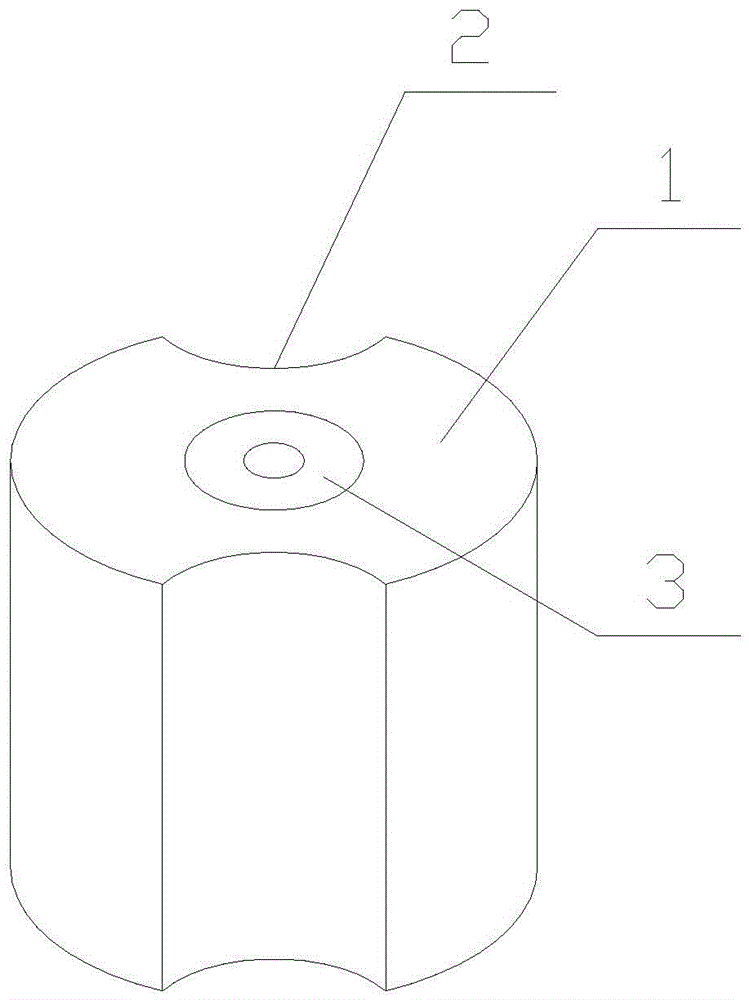

[0042] Such as Figure 7-10 Shown is a sewage oxidation treatment device of the present invention, comprising a rotating body 1 provided with an arc groove 2, the center of the rotating body 1 is provided with a connecting hole 3 connected to the rotating mechanism; the arc groove 2 has at least two are evenly spaced on the rotating body 1. The rotating body 1 is a cylindrical structure, and the upper bottom surface and the lower bottom surface of the rotating body 1 are provided with connecting holes 3; the rotating mechanism is a motor, and the connection between the motor output shaft 7 and the upper bottom surface of the rotating body 1 Holes 3 are connected.

[0043] The rotating body 1 described in this embodiment is provided with three arc-shaped grooves 2, and the three arc-shaped grooves 2 are evenly arranged at equal intervals; the three arc-shaped grooves 2 are arranged on the rotating body 1 from top to bottom. The side of the arc; the radius of the arc of the ar...

Embodiment 3

[0048] Such as Figure 11-14 As shown, a sewage oxidation treatment device of the present invention includes a rotating body 1 provided with an arc-shaped groove 2, and the center of the rotating body 1 is provided with a connecting hole 3 connected to the rotating mechanism; the arc-shaped groove 2 has at least Two are evenly arranged on the rotating body 1 at equal intervals. The rotating body 1 is a cylindrical structure, and the upper bottom surface and the lower bottom surface of the rotating body 1 are provided with connecting holes 3; the rotating mechanism is a motor, and the connection between the motor output shaft 7 and the upper bottom surface of the rotating body 1 Holes 3 are connected.

[0049] The rotating body 1 described in this embodiment is provided with four arc-shaped grooves 2, and the four arc-shaped grooves 2 are evenly arranged at equal intervals; the four arc-shaped grooves 2 are arranged on the rotating body from top to bottom. 1; the radius of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com