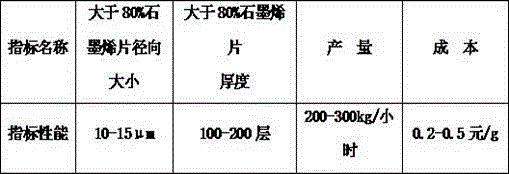

Method of preparing graphene nanoplatelets through air flow stripping classification

A technology of graphene microchips and airflow, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve the problems that restrict the large-scale production of graphene sheets, extremely high equipment requirements, and inability to continue production, etc., reaching a significant market The effect of application value, easy preparation method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

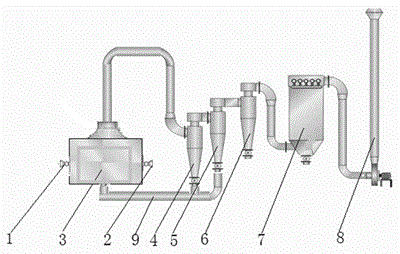

Image

Examples

Embodiment 1

[0039] The method for preparing graphene microsheets by air-flow exfoliation classification:

[0040] (1) Dimethyl sulfoxide, formamide, and polyethylene glycol were prepared as an intercalation agent at a mass ratio of 2:3:1, and then the flake graphite powder was soaked in the intercalation agent for more than 48 hours, and then dried by centrifuge , drying to obtain pre-intercalated graphite;

[0041] (2) Melt sodium chloride and magnesium chloride at a mass ratio of 1:1 in a high-speed mixing reactor at 280-300°C, and add the pre-intercalated graphite obtained in step (1) into the molten chloride under nitrogen protection conditions In the sodium and magnesium chloride melt, stir and disperse at a speed of 300r / min for 35min, the graphite layer is filled with ion melt of sodium chloride and magnesium chloride, then discharge, cool to room temperature under the protection of nitrogen, and pulverize through a 50-mesh sieve. Wherein the mass ratio of pre-intercalation graphi...

Embodiment 2

[0048] Utilize the method for airflow stripping classification to prepare graphene sheet:

[0049] (1) Prepare intercalation agent with dimethyl sulfoxide, formamide, and polyethylene glycol at a mass ratio of 3:3:1, and then soak expanded graphite with a radial size larger than 50 microns in the intercalation agent for more than 48 hours , filtered and dried by a centrifuge to obtain pre-intercalated graphite;

[0050] (2) Melt sodium chloride and magnesium chloride at a mass ratio of 1:1 in a high-speed mixing reactor at 280-300°C, and add the pre-intercalated graphite obtained in step (1) into the molten chloride under nitrogen protection conditions In the sodium and magnesium chloride melt, stir and disperse at a speed of 500r / min for 25min, the graphite layer is filled with ion melt of sodium chloride and magnesium chloride, then discharge, cool to room temperature under the protection of nitrogen, and pulverize through a 50-mesh sieve. Wherein the mass ratio of pre-inte...

Embodiment 3

[0057] Utilize the method for airflow stripping classification to prepare graphene sheet:

[0058] (1) Dimethyl sulfoxide, formamide, and polyethylene glycol are prepared as an intercalation agent at a mass ratio of 3:5:1, and then thermal cracking graphite powder with a radial size greater than 50 microns is soaked in the intercalation agent More than 48h, filter and dry by centrifuge to obtain pre-intercalated graphite;

[0059] (2) Melt sodium chloride and magnesium chloride at a mass ratio of 1:1 in a high-speed mixing reactor at 280-300°C, and add the pre-intercalated graphite obtained in step (1) into the molten chloride under nitrogen protection conditions In the sodium and magnesium chloride melt, stir and disperse at a speed of 800r / min for 35min, the graphite layer is filled with ion melt of sodium chloride and magnesium chloride, then discharge, cool to room temperature under the protection of nitrogen, and pulverize through a 50-mesh sieve. Wherein the mass ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com