A transmission for a front-drive plug-in hybrid vehicle

A technology of hybrid electric vehicle and transmission device, which is applied to the arrangement of multiple prime movers of power device, air pressure power device, and general power device, and can solve the problems of unable to optimize the working state of the motor and limit the matching ability, and achieve Facilitate product development, meet power requirements, and achieve flexible structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

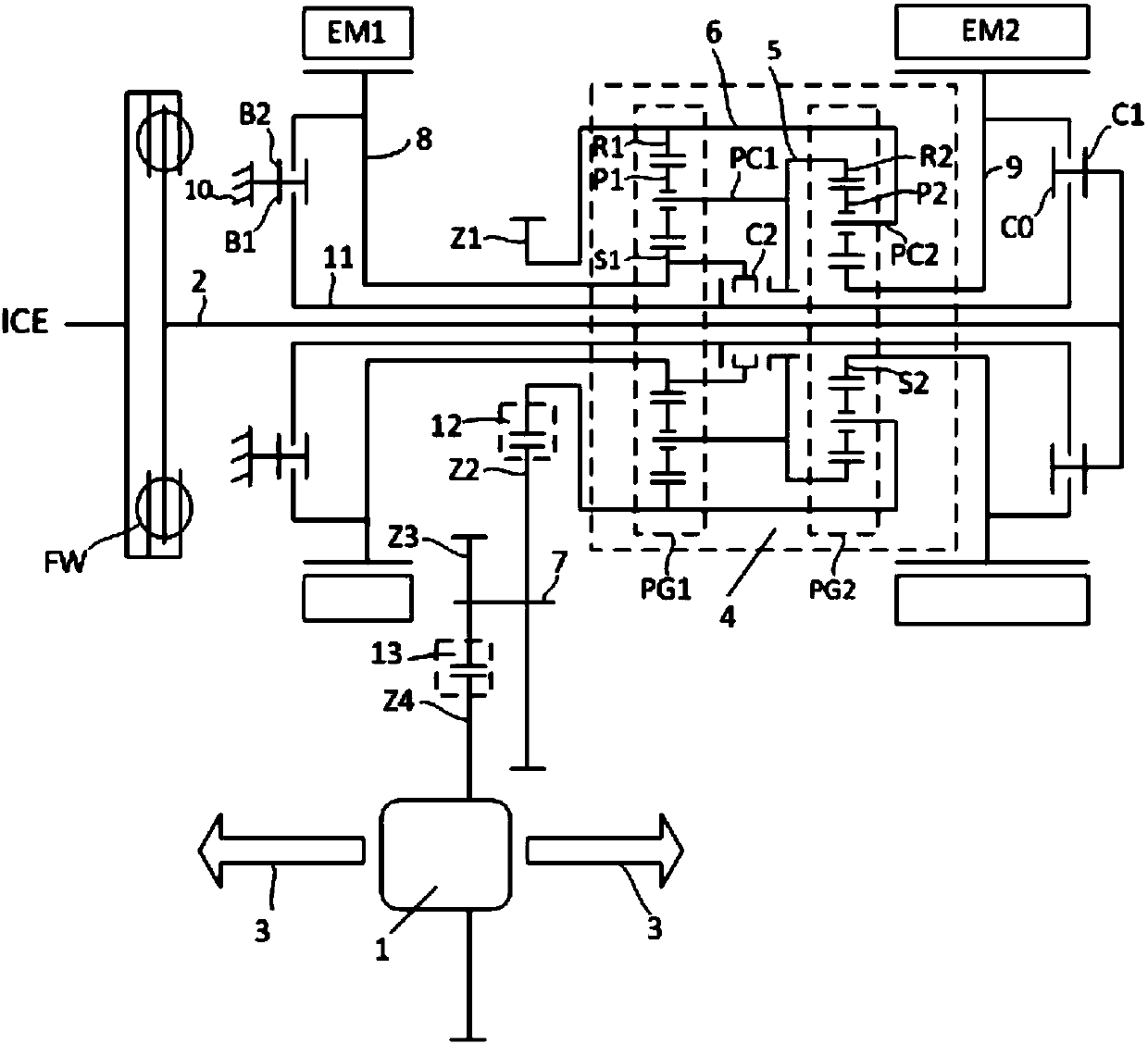

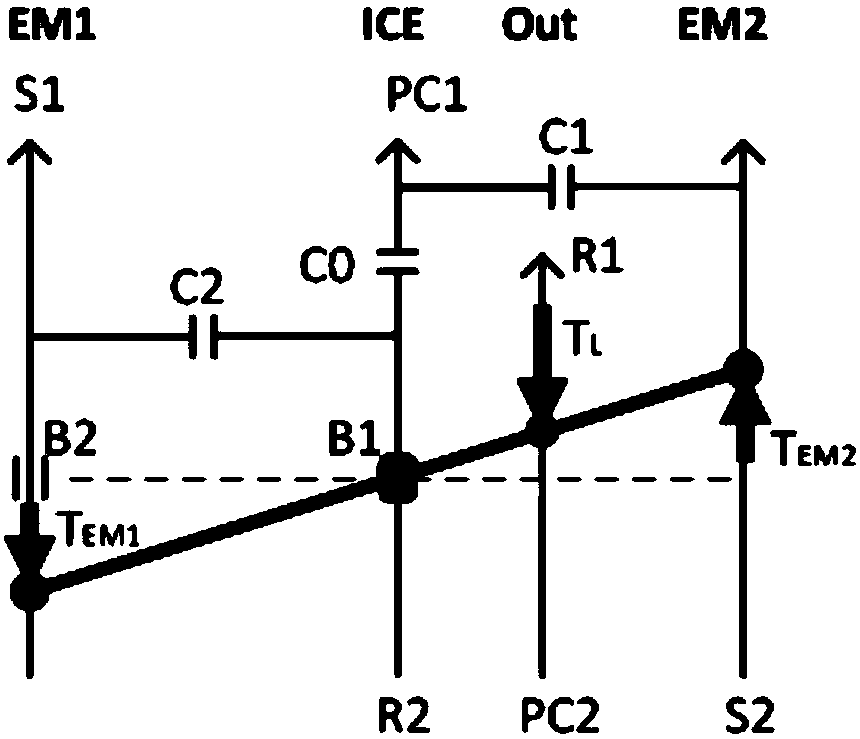

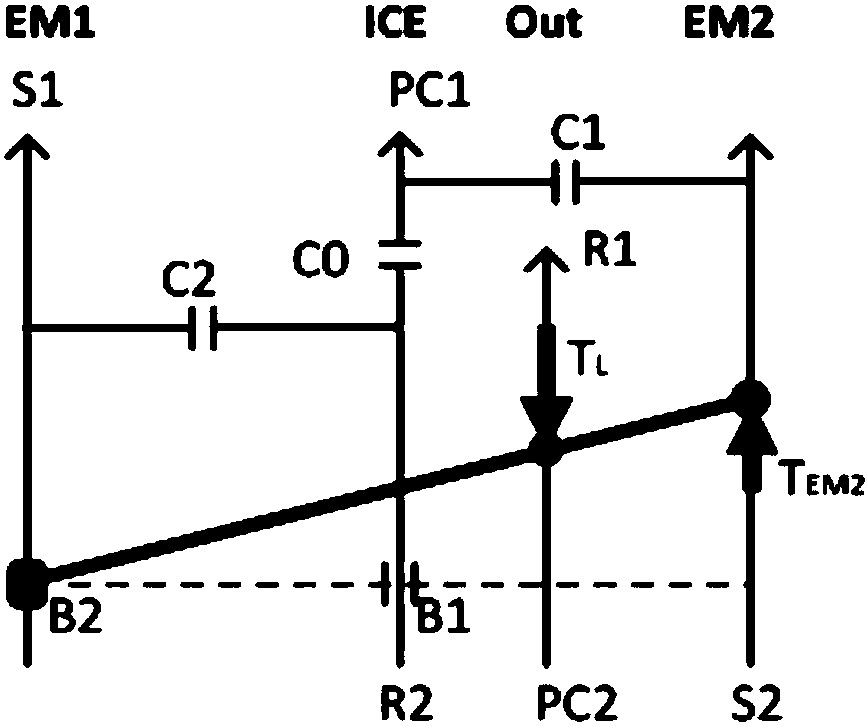

[0036] A transmission for a front-drive plug-in hybrid vehicle such as figure 1 As shown, it includes small motor EM1, large motor EM2, first clutch C0, second clutch C1, third clutch C2, differential 1, input shaft 2, output shaft 3, first single planetary row PG1, second single The planetary row PG2, the first brake B1, the second brake B2, the first reduction gear Z1, the second reduction gear Z2, the third reduction gear Z3, the first clutch C0 and the first clutch C1 in this embodiment are normally open type Clutch; the first single planetary row PG1 includes the first sun gear S1, the first planetary gear P1, the first planetary carrier PC1 and the first outer ring gear R1, the first planetary gear P1 is installed on the first planetary carrier PC1, the first The planetary gear P1 meshes with the first sun gear S1 and the first outer ring gear R1 respectively; the second single planet row PG2 includes the second sun gear S2, the second planetary gear P2, the second plane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com