Method for efficiently operating switch reluctance (SR) motor at low and high speed and SR motor thereof

A high-efficiency, high-speed technology, applied to synchronous motors for single-phase current, the shape/style/structure of winding conductors, etc., can solve the problem of no further help in improving the operating efficiency of SR motors, and achieve improved efficiency and high operation. Efficiency, high-efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

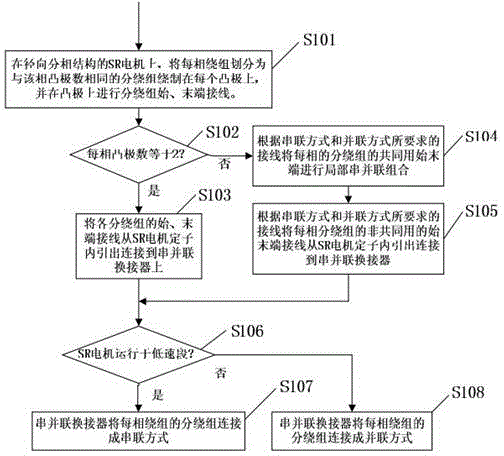

[0034] Example: as figure 1 Shown as a flowchart, the basic steps include:

[0035] S101: On the SR motor with radial phase split structure, each phase winding is divided into sub-windings with the same number of salient poles as the phase, wound on each salient pole to which the phase belongs, and sub-windings are performed on the salient poles Beginning and end wiring;

[0036] S102: Determine whether the number of salient poles in each phase is equal to 2, if so, go to S103, otherwise (that is, the number of salient poles in each phase is greater than 2), go to step S104;

[0037] S103: Connect the start and end wiring of each sub-winding from the SR motor stator to the series-parallel converter;

[0038] S104: According to the wiring required by the series mode and the parallel mode, the common start and end of each phase winding are combined in local series and parallel;

[0039] S105: According to the wiring required by the series mode and the parallel mode, connect t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com