A treatment method for scrap banknotes to be crushed after being dried and pressed into blocks for engraving and filling

A treatment method and post-drying technology, applied in special decorative structures, techniques for producing decorative surface effects, decorative arts, etc., can solve problems such as waste, reduce treatment costs, reduce environmental pollution, and improve the economy and society benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

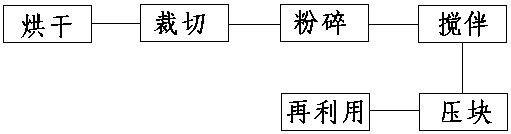

[0013] A processing method for scrap banknotes to be crushed after being dried and then briquetting, engraved and filled, characterized in that the steps of the method are as follows:

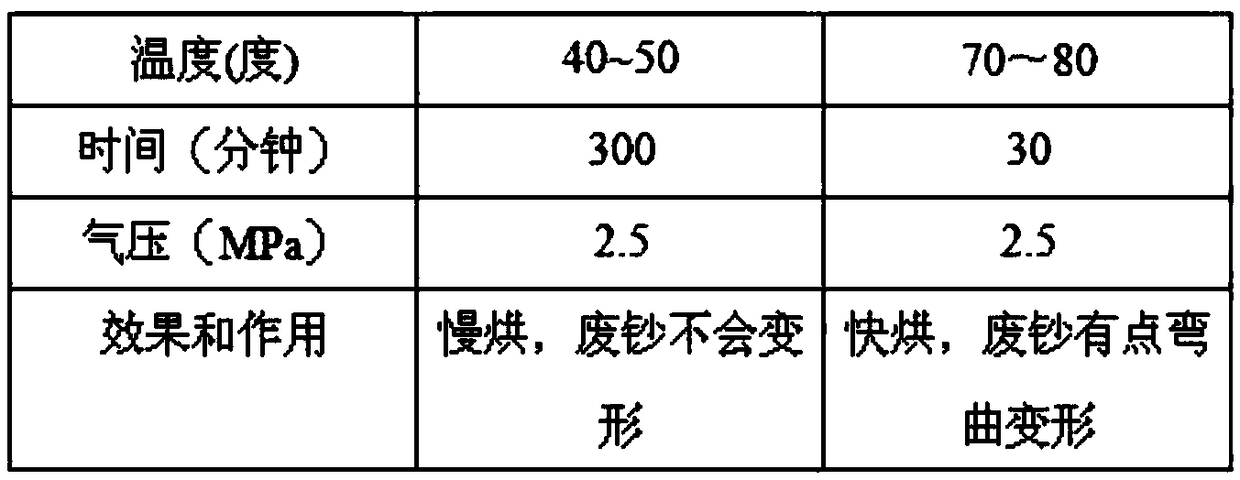

[0014] Step 1. Use the dryer to dry the water and ink in the banknotes: put 5,000 large banknotes into the workbench of the dryer, adjust the temperature of the dryer to 70-80 degrees, and the pressure of the blower to 2.5MPa , point the blowing nozzle at the waste banknotes, chop up and down, and blow air back and forth. After baking for 10 minutes, turn off the heater, and the hair dryer continues to blow. After 5 minutes, turn off the hair dryer and take out the dried waste banknotes;

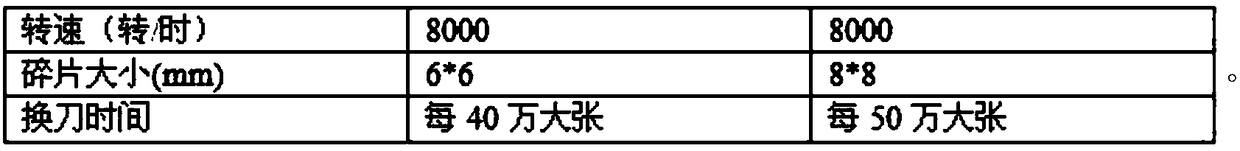

[0015] Step 2. Smash the dried large waste banknotes: put the dried large waste banknotes into the flat table of the paper feeding part of the large shredder with a paper tow truck, and adjust the paper feeding speed to 8000 rpm. A piece of banknotes is conveyed to the rotary cutter through the plane conveyor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com