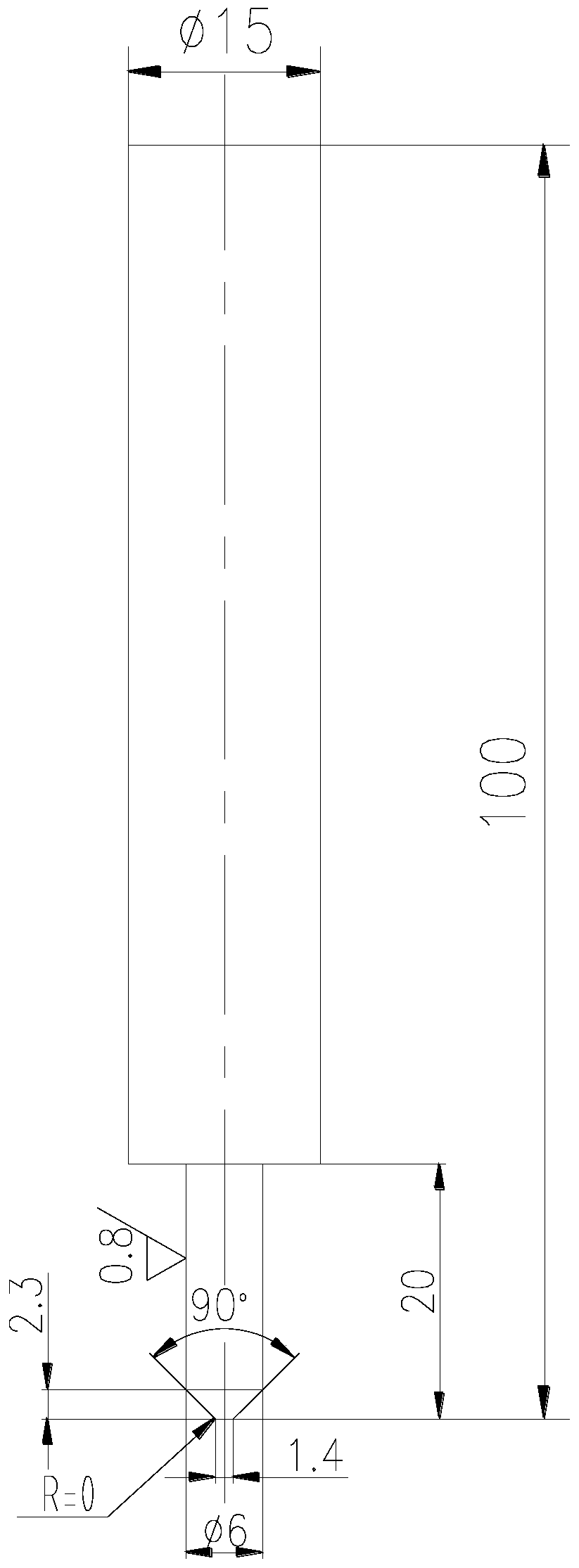

Method for Automatically Machining 90° Inner Hole Sealing Groove by Digital Milling Machine Tool

A technology of sealing grooves and inner holes, which is applied in the field of mechanical parts processing, can solve problems such as high requirements for workers, unfavorable high-efficiency processing of parts, and easy quality problems, so as to improve production efficiency, reduce scrap rate, and improve surface roughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] 1. Inner sealing groove processing:

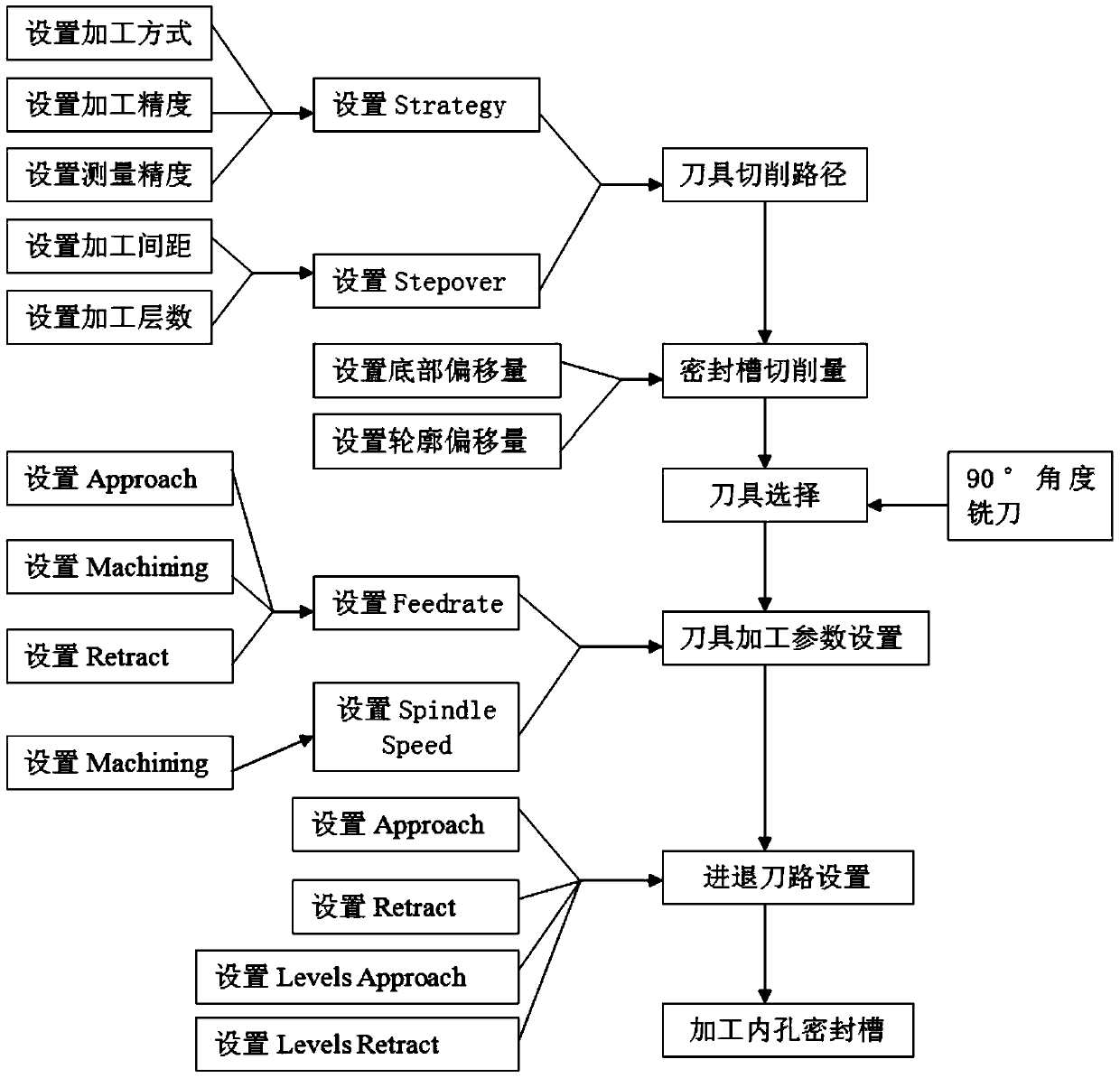

[0020] When machining the inner hole sealing groove, select the command (Profilr Contouring) in the CATIA program, and set the parameters according to the material steps:

[0021] (1) Set the tool cutting path:

[0022] 1. Set in the Profilr Contouring option:

[0023] Processing method: Tool path style is selected as: Zig zag (serrated cutting)

[0024] Machining tolerance: Machining tolerance: set to: 0.005mm. According to the precision of the current digital milling machine, if the setting is lower than 0.005mm, it is easy to cause the hole size to be out of tolerance when machining the inner hole sealing groove.

[0025] Processing accuracy: Fixture accuracy is selected as: 0.005mm. According to the surface accuracy of the parts processed by the current digital milling machine tool, if the setting is lower than 0.005mm, the surface accuracy of the sealing groove will not meet the design requirements when processing the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com