A treatment method and treatment device for industrial waste gas containing nitrogen oxides

A technology for industrial waste gas and treatment methods, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems such as high cost, easy scaling and clogging, achieve low operating costs, meet denitration requirements, and economic and environmental benefits considerable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

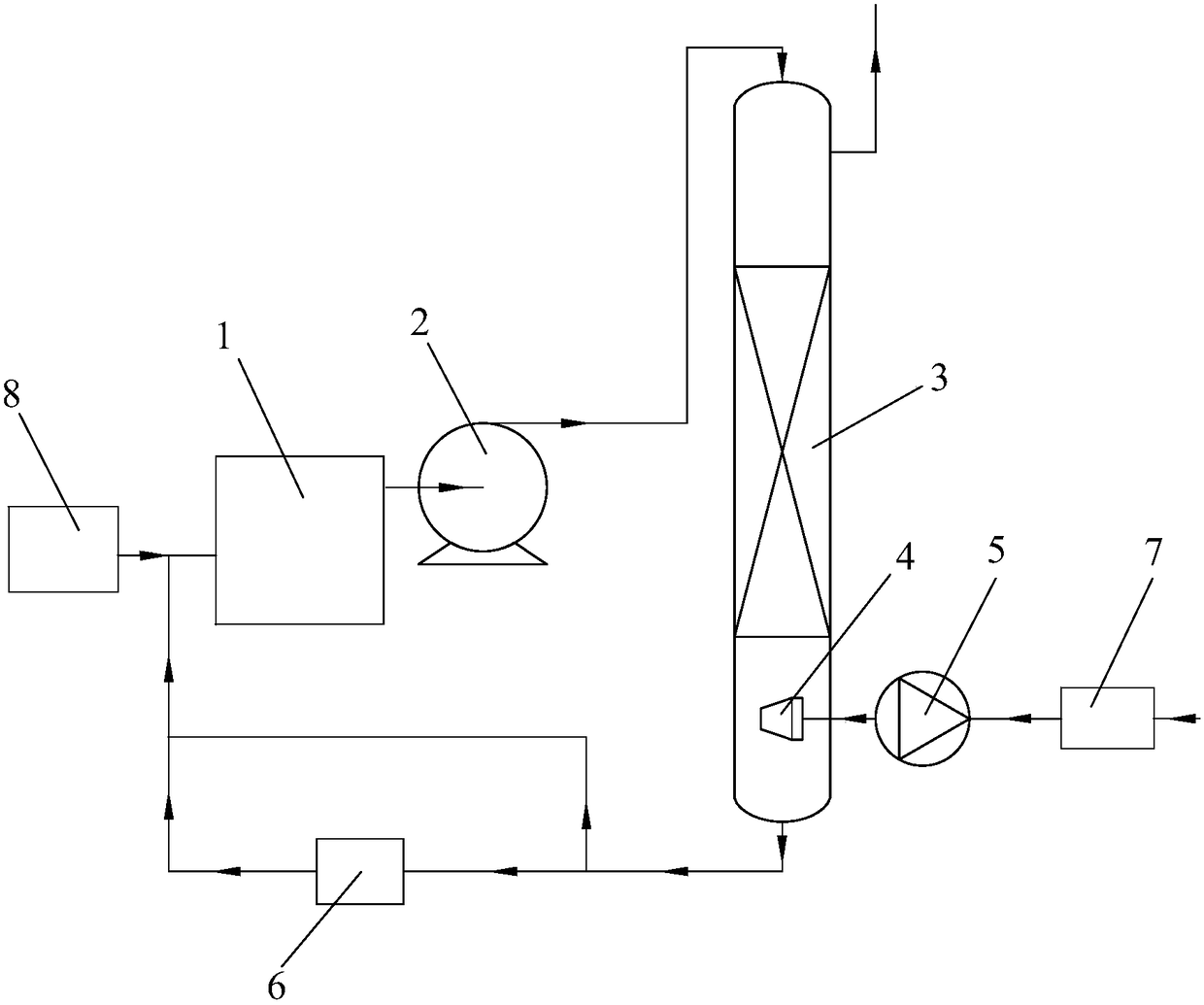

[0018] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

[0019] The invention provides a treatment method and a treatment device for industrial waste gas containing nitrogen oxides, which can recycle permanganate as an oxidation and denitrification agent, thereby reducing operating costs.

[0020] Such as figure 1 As shown, the exhaust gas enters the desulfurization device 7 for desulfurization treatment after dedusting, and the desulfurized exhaust gas is input from the bottom of the denitrification tower 3 through the conveying device. Specifically, the delivery device includes a fan 5, the fan 5 is connected to the denitrification tower 3 and the desulfurization device 7, and the output end of the fan 5 is provided with an aeration head 4, and the fan 5 can transport the desulfurized waste gas to the The bottom of the denitrification tower 3. The denitrification tower can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com