Continuous distillation trichlorosilane gasification supply device

A trichlorosilane and supply device technology, which is applied in steam condensation, post-processing devices, gaseous chemical plating, etc., can solve the problems of increased cost of peripheral equipment, increased condenser capacity and heat transfer area, increased cost, etc. Achieve the effects of energy cost reduction, device cost reduction, and device installation area reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

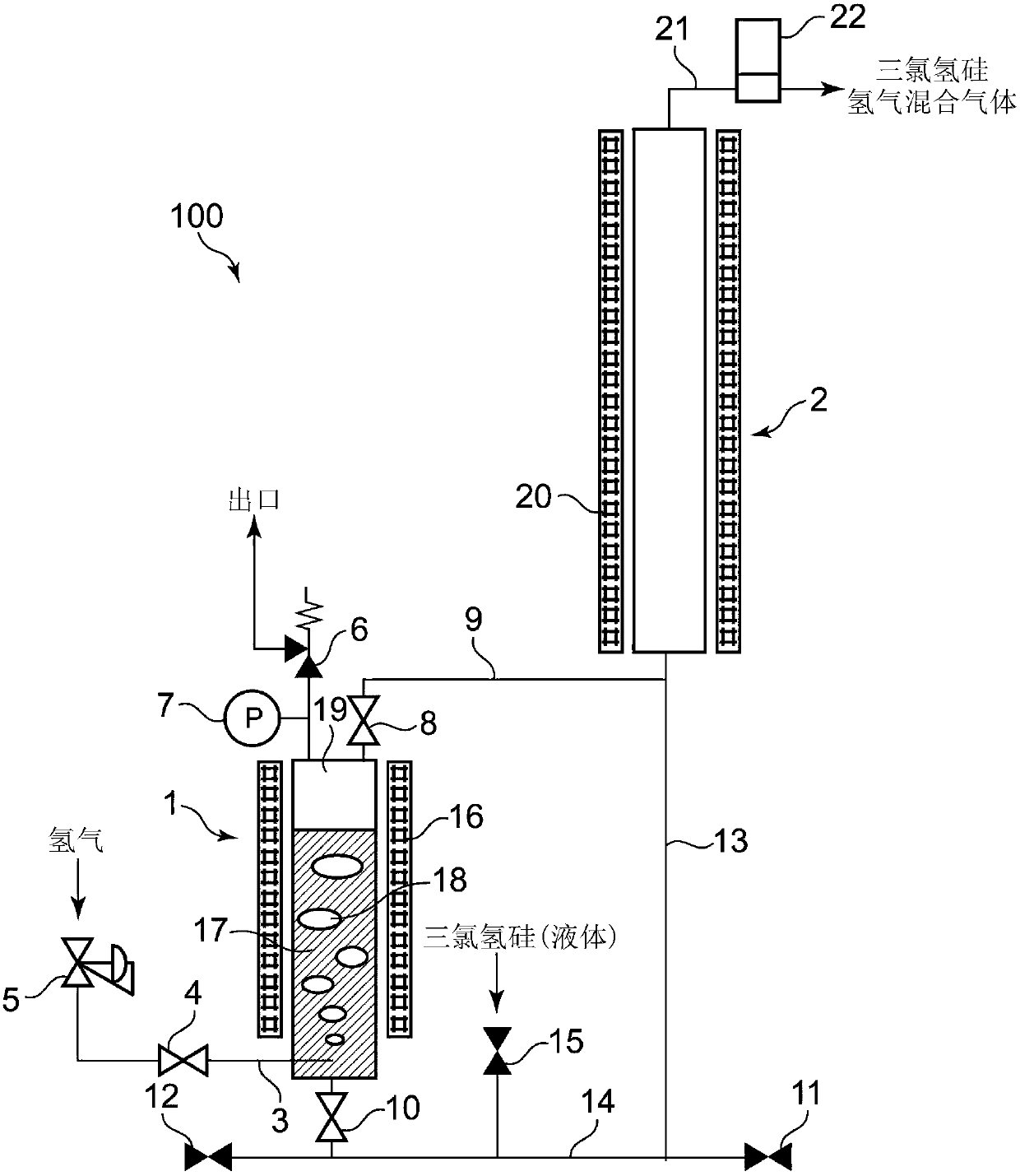

[0110] The volume of the main equipment evaporator of the device of the present invention is about 3 liters, and the heat transfer area of the condenser is about 0.9m 2 . The pressure regulator is a so-called mechanical pressure reducing valve, which is connected to one silicon epitaxial growth apparatus for testing. A so-called single-wafer type device was used for the test silicon epitaxial growth device. The epitaxial substrate is made of P coated with oxide film inside +substrate. During the epitaxial growth process, the growth rate of the epitaxial film is 3 μm / min, the thickness is 4.5 μm, and the growth time is 90 seconds. It is 12 liters / min. On the other hand, the trichlorosilane produced by the device of the present invention under the conditions that the total pressure is 0.149±0.0015Mpa (gauge pressure), the condensation temperature is 15.0±0.1°C, and the temperature of the trichlorosilane liquid in the evaporator is 35±0.5°C The concentration of the mixed g...

Embodiment 2

[0112] The effect of using a precision pressure regulator is reviewed. The volume of the main equipment evaporator of the device of the present invention is about 3 liters, and the heat transfer area of the condenser is about 0.9m 2 . The pressure regulator is an electronic pressure control valve with a very fast response speed, and it is connected to a silicon epitaxial growth device for testing. A so-called single-wafer type device was used for the test silicon epitaxial growth device. The epitaxial substrate is made of P coated with oxide film inside + substrate. During the epitaxial growth process, the growth rate of the epitaxial film is 3 μm / min, the thickness is 4.5 μm, and the growth time is 90 seconds. It is 12 liters / min. On the other hand, the trichlorosilane produced by the device of the present invention under the conditions that the total pressure is 0.150±0.0005Mpa (gauge pressure), the condensation temperature is 15.0±0.1°C, and the temperature of the tr...

Embodiment 3

[0114] The effect of increasing the flow rate of trichlorosilane·hydrogen gas mixture was examined. The volume of the main equipment evaporator of the device of the present invention is about 3 liters, and the heat transfer area of the condenser is about 0.9m 2 . The pressure regulator is an electronic pressure control valve with a very fast response speed, and it is connected to a silicon epitaxial growth device for testing. A so-called single-wafer type device was used for the test silicon epitaxial growth device. The epitaxial substrate is made of P coated with oxide film inside + substrate. During the epitaxial growth process, the growth rate of the epitaxial film is 3.45 μm / min, the thickness is 4.5 μm, and the growth time is 78 seconds. The period is 18 liters / min. On the other hand, the device of the present invention produces trichlorosilane under the conditions that the total pressure is 0.150±0.0005Mpa (gauge pressure), the condensation temperature is 15.1±0.2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com