Flexible circuit board and manufacturing method thereof

A flexible circuit board and manufacturing method technology, applied in printed circuit manufacturing, multi-layer circuit manufacturing, printed circuit and other directions, can solve the problems of poor dry film resolution, affecting the production of thin circuits, etc. effect of line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

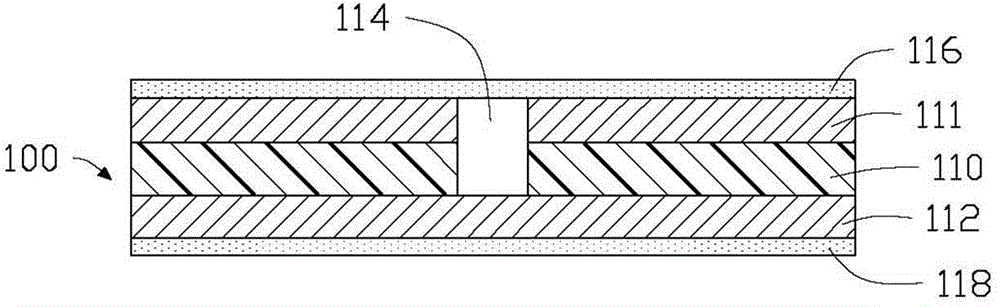

[0043] see Figure 1 to Figure 8 , the first embodiment of the present invention provides a method for manufacturing a double-layer flexible circuit board, including the following steps:

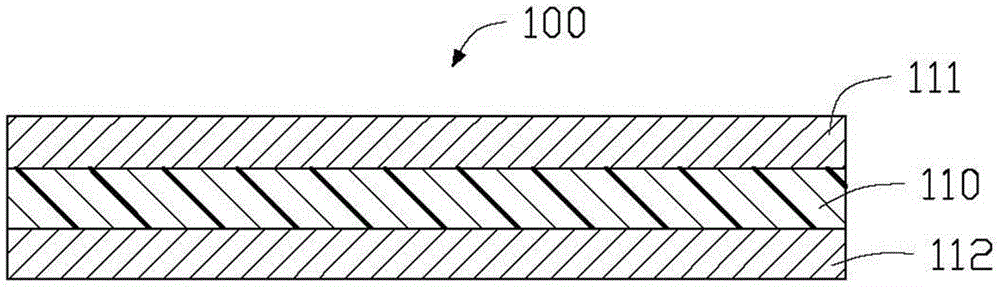

[0044] As a first step, see figure 1 , a substrate 100 is provided.

[0045] In this embodiment, the substrate 100 is a double-sided board, and the substrate 100 includes a base layer 110 , a first bottom copper layer 111 and a second bottom copper layer 112 formed on opposite sides of the base layer 110 .

[0046] In this embodiment, the base layer 110 is a flexible resin layer, such as polyimide (PI), polyethylene terephthalate (PET) or polyethylene naphthalate ( Polyethylene Naphthalate, PEN).

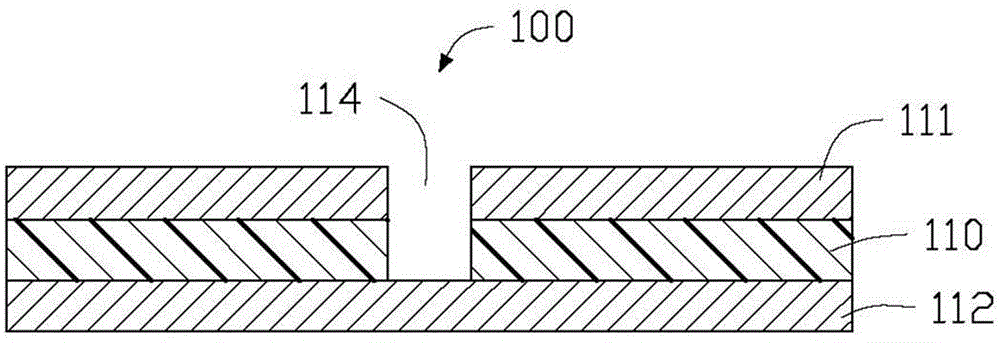

[0047] For the second step, see figure 2 , a first hole 114 is opened on the substrate 100 . In this embodiment, the first hole 114 is a blind hole, which passes through the first bottom copper layer 111 and the base layer 110 and ends at the second bottom copper layer 112 . The first hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com