Gas steam back-pressure cooling four-grade utilization electricity and water cold and hot steam heating system

A technology of gas steam and back pressure, which is applied in the direction of steam engine devices, refrigerators, refrigeration and liquefaction, etc., and can solve the problems of water resource consumption, gas emission, and increased operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

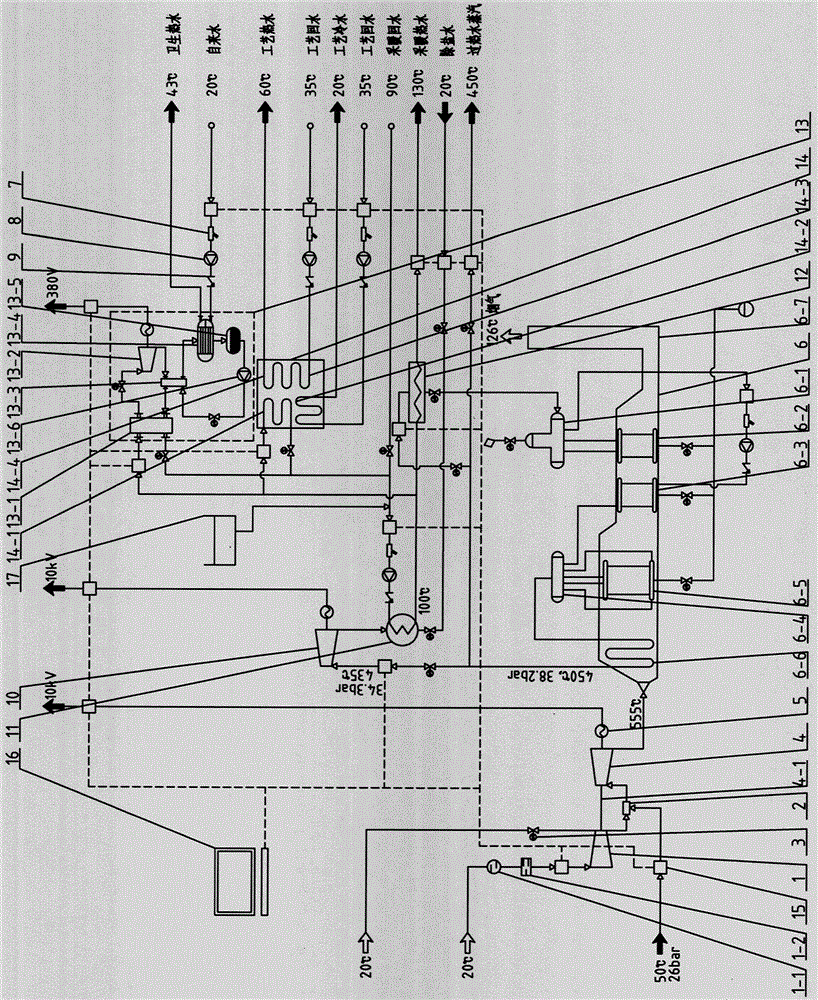

[0068] The embodiment of the four-stage gas steam back pressure cooling and heating system using electric water cooling and heating proposed by the present invention is attached figure 1 As shown, the description is as follows: it consists of a compressor 1 (with a pressure ratio of 16.8:1), a combustion chamber 2 (stainless steel with a volume of 160L), and a gas turbine 4 with a power generation capacity of 15MW to form a gas turbine;

[0069] Compressor 1, gas turbine 4, (rated power 15MW, rated voltage 10.5kV, rated current 1031A, rated frequency 50Hz, rated speed 1500r / min, power factor 0.8 synchronous) generator 5, through (stainless steel with a diameter of 75mm) The single-shaft 4-1 connection is integral and shares the base to form the first-stage cycle power generation and compressor device of the gas turbine (with a thermal efficiency of 34.8%);

[0070] (Stainless steel with a diameter of 400mm and a wall thickness of 4mm) the gas pipeline is connected to the gas i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com