Production method for canister of canister respirator

A technology for gas masks and production methods, applied in the direction of respiratory filters, life-saving equipment, respiratory protection containers, etc., can solve the problems of uneven quality of production products, difficulty in large-scale production, and large human operation errors, etc., to achieve The effect of improving production efficiency, improving production technology and raising standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Now the present invention is further described in conjunction with description of drawings and embodiments:

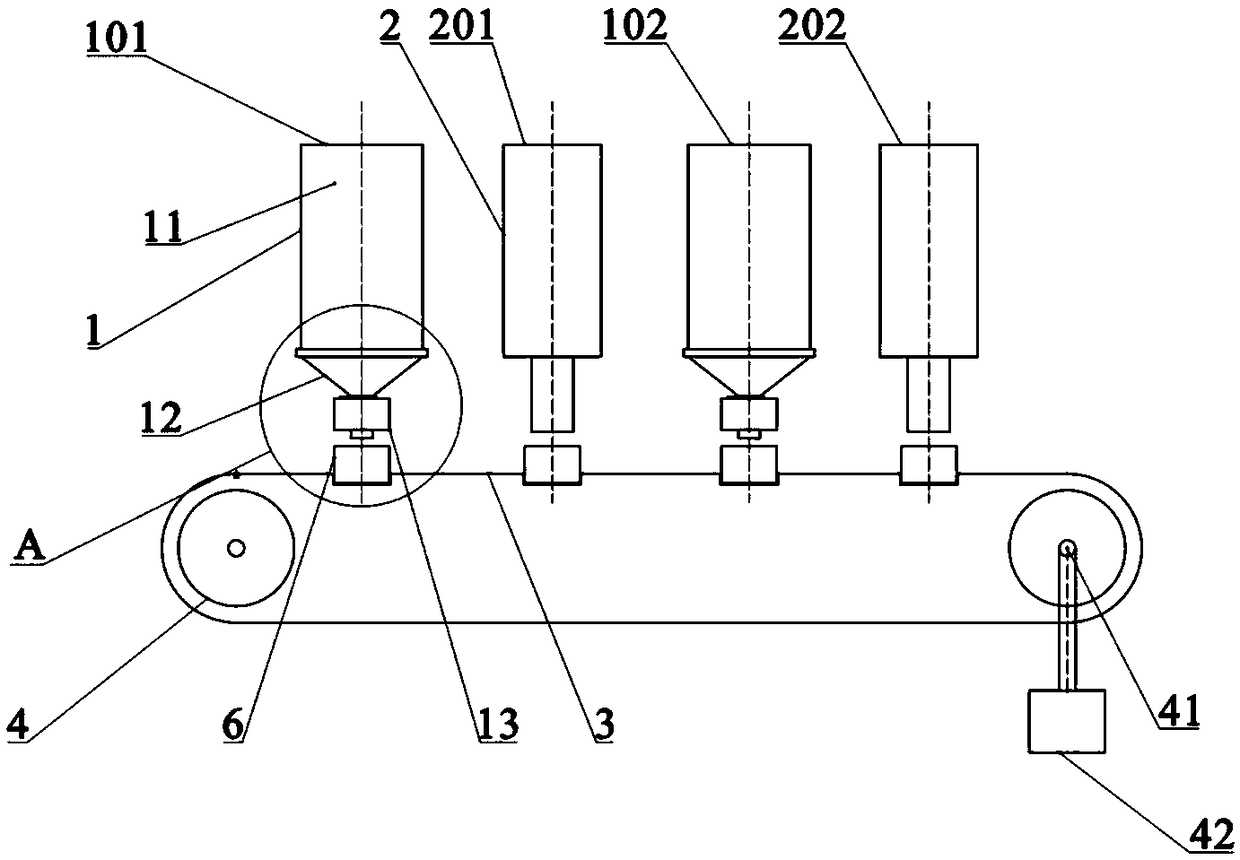

[0034] like Figure 1-3 Shown, a kind of canister production method of gas mask comprises the following steps:

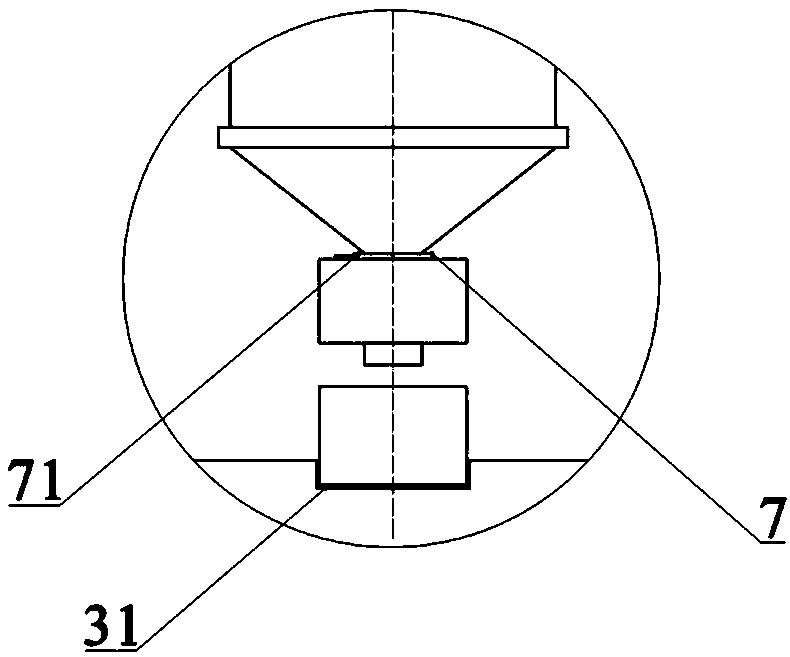

[0035] First, the canister 6 to be filled is placed on the conveyor belt 3, and is transported to the first filling device 101 via the conveyor belt 3, and filled with the first canister;

[0036] Afterwards, the canister 6 continues to be transported to the first interlayer machine 201 through the conveyor belt 3, and the first interlayer is placed;

[0037] Then, the canister 6 continues to be transported to the second filling device 102 via the conveyor belt, and filled with the second canister;

[0038] Finally, the canister 6 is transported to the second interlayer machine 202 via the conveyor belt 3, where the second interlayer is placed.

[0039] The automatic production system is adopted to improve the production process of the existing can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com