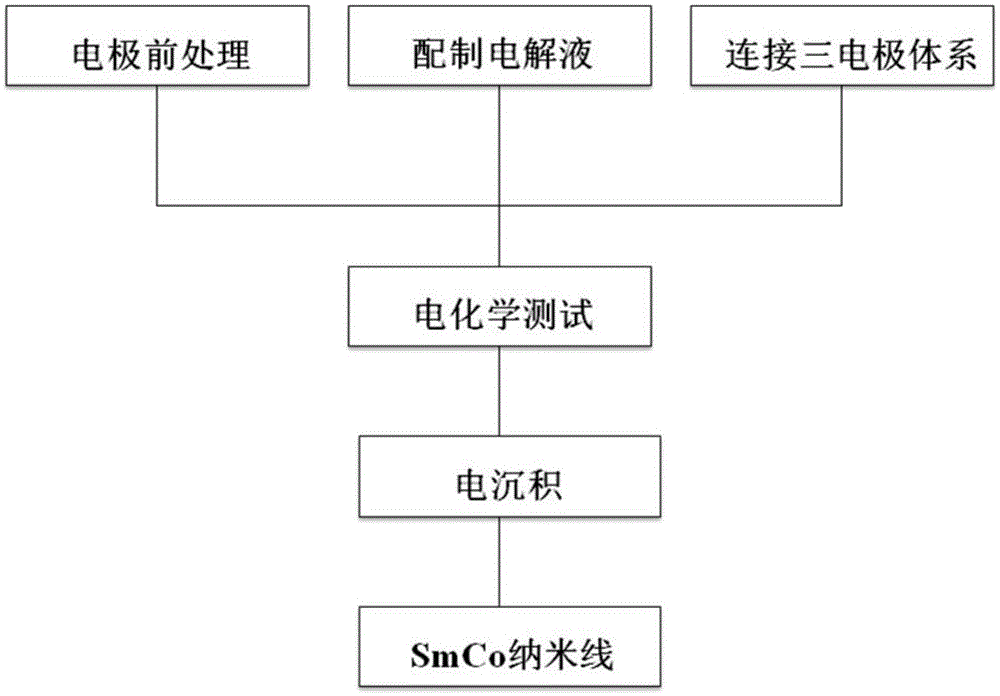

Preparation method of template-free electro-deposition SmCo nanowires

A nanowire and electrodeposition technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of time-consuming and labor-intensive template method, and achieve time-saving operation, high conductivity and high purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

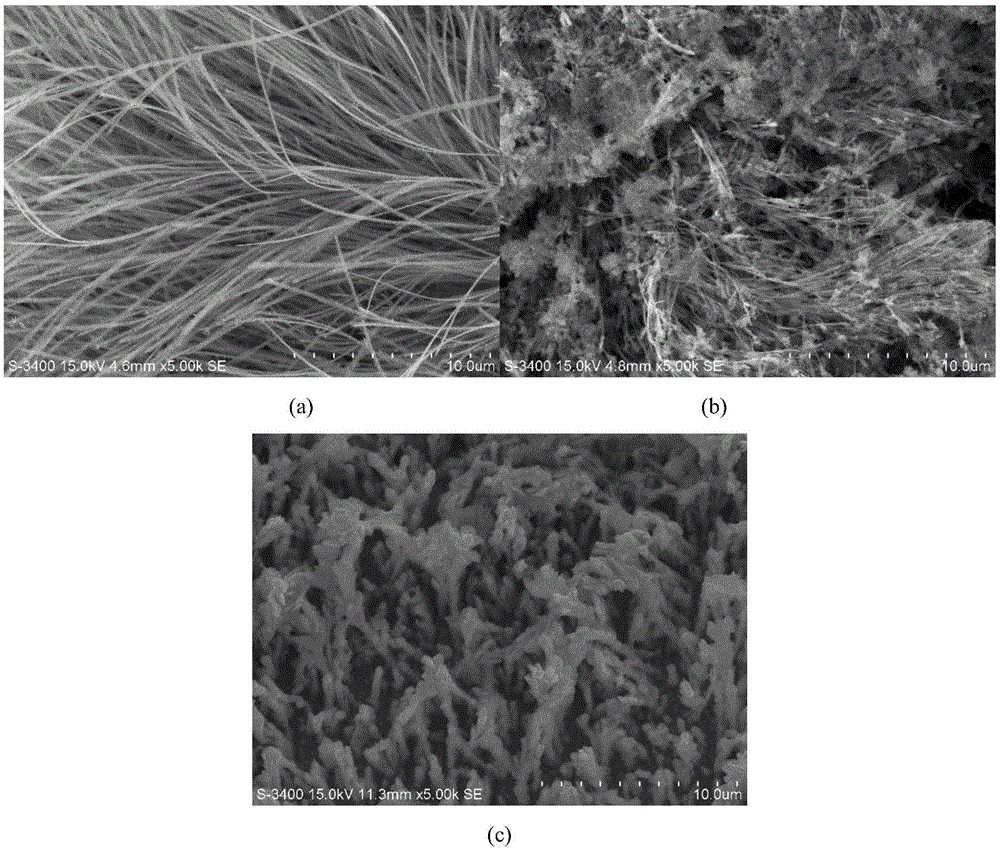

Embodiment 1

[0039] 1. Electrode pretreatment, the working electrode (WE) is a tungsten sheet, the counter electrode (CE) is a cobalt sheet, and the reference electrode (RE) is Co 2+ / Co electrode, which consists of cobalt wire impregnated with 40:60mol% CoCl 2 -EMIC ionic liquids in porous glass tubes. Before use, all the electrodes were polished to a mirror surface with sandpaper, and the cobalt sheet and cobalt wire were ultrasonically washed with acetone for 20 minutes to remove organic matter, and then washed with deionized water and dried for later use. The tungsten sheet of the working electrode should be used first with 2MHNO 3 Ultrasound for 20 minutes to wash away oxides, then use acetone for 20 minutes to wash away organic matter, and finally wash with deionized water and dry for later use;

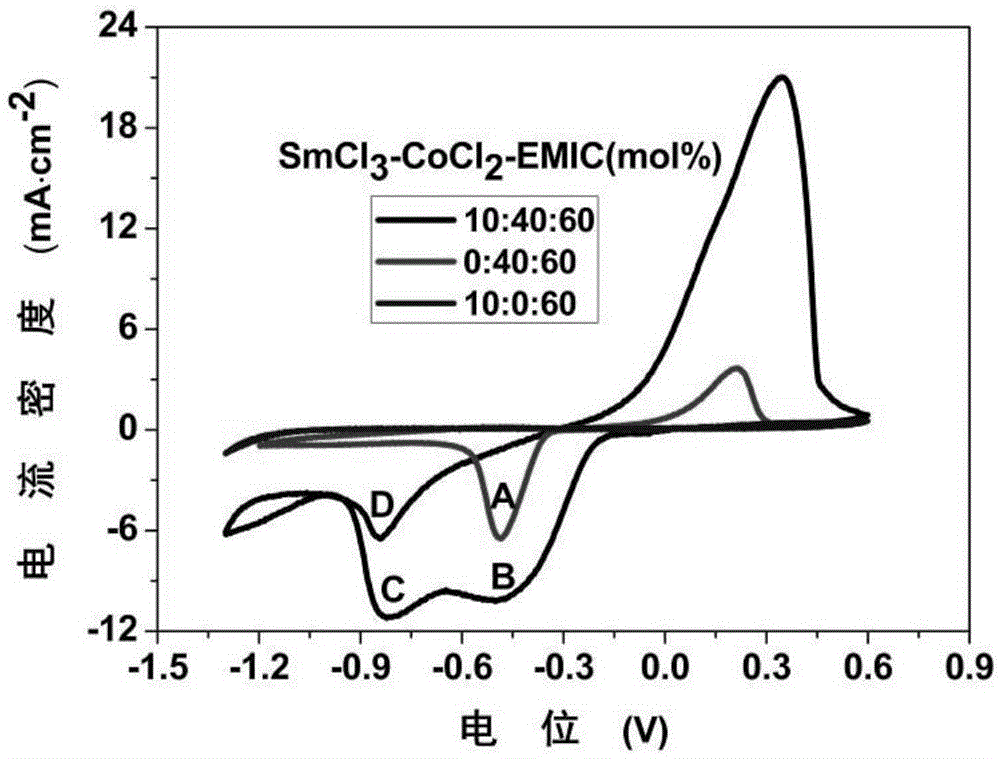

[0040] 2. To prepare the electrolyte, weigh SmCl in the glove box according to the molar ratio of 1.67:40:60 3 、CoCl 2 and EMIC, mix evenly, heat at a rate of 0.5°C / min, keep at 120°C f...

Embodiment 2

[0044] 1. Electrode pretreatment, the working electrode (WE) is a tungsten sheet, the counter electrode (CE) is a cobalt sheet, and the reference electrode (RE) is Co 2+ / Co electrode, which consists of cobalt wire impregnated with 40:60mol% CoCl 2 -EMIC ionic liquids in porous glass tubes. Before use, all the electrodes were polished to a mirror surface with sandpaper, and the cobalt sheet and cobalt wire were ultrasonically washed with acetone for 20 minutes to remove organic matter, and then washed with deionized water and dried for later use. The tungsten sheet of the working electrode should be used first with 2MHNO 3 Ultrasound for 20 minutes to wash away oxides, then use acetone for 20 minutes to wash away organic matter, and finally wash with deionized water and dry for later use;

[0045] 2. To prepare the electrolyte, weigh SmCl in the glove box according to the molar ratio of 1.67:40:60 3 、CoCl 2 and EMIC, mix evenly, heat at a rate of 0.5°C / min, keep at 120°C f...

Embodiment 3

[0048] 1. Electrode pretreatment, the working electrode (WE) is a tungsten sheet, the counter electrode (CE) is a cobalt sheet, and the reference electrode (RE) is Co 2+ / Co electrode, which consists of cobalt wire impregnated with 40:60mol% CoCl 2 -EMIC ionic liquids in porous glass tubes. Before use, all the electrodes were polished to a mirror surface with sandpaper, and the cobalt sheet and cobalt wire were ultrasonically washed with acetone for 20 minutes to remove organic matter, and then washed with deionized water and dried for later use. The tungsten sheet of the working electrode should be used first with 2MHNO 3 Ultrasound for 20 minutes to wash away oxides, then use acetone for 20 minutes to wash away organic matter, and finally wash with deionized water and dry for later use;

[0049] 2. To prepare the electrolyte, weigh SmCl in the glove box according to the molar ratio of 1.67:40:60 3 、CoCl 2 and EMIC, mix evenly, heat at a rate of 0.5°C / min, keep at 120°C f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com