High-performance REBCO multilayer film, application and preparation method for high-performance REBCO multilayer film

A multi-layer, high-performance technology, applied in coatings, metal material coating processes, ion implantation plating, etc., can solve problems such as affecting film performance and current inability to conduct, and achieve high critical current density, high shape The effect of morphology stability and repeatability, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

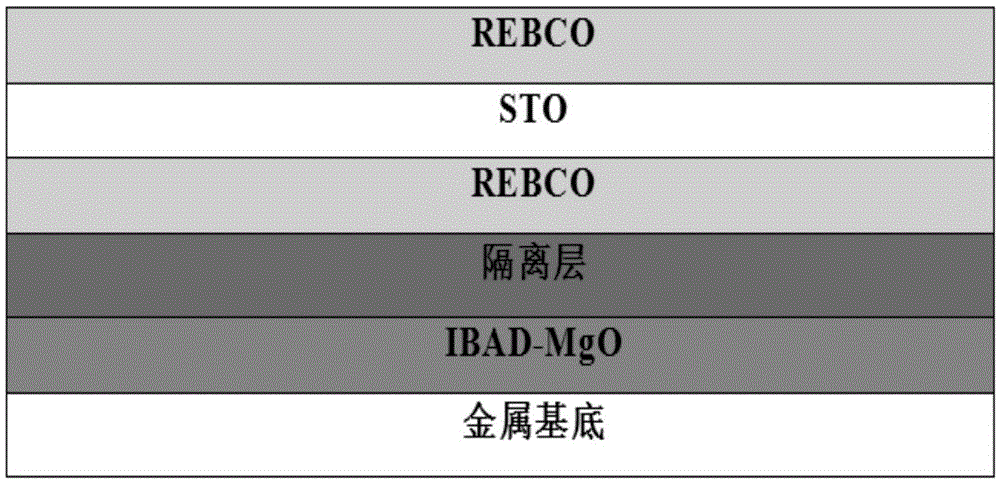

[0054] This embodiment provides a method for preparing a REBCO multilayer film on an IBAD-MgO substrate, comprising the following steps:

[0055] Step 1. Install the REBCO and STO targets prepared by high-temperature sintering into the target holder in the cavity;

[0056] Step 2, winding the IBAD-MgO base tape coated with an isolation layer in a multi-channel pulsed laser deposition system;

[0057] Step 3. Close the door of the coating system and evacuate to the required vacuum degree of 1×10 -7 , and then start the heater to raise the temperature to the temperature value required by the REBCO thin film process, the temperature is 750°C;

[0058] Step 4, feed oxygen, adjust the air pressure of the gas to the air pressure value required by the REBCO thin film coating process, and the air pressure is 200mTorr;

[0059] Step 5. Start the laser target rotation and scanning system, start the energy and frequency of the excimer laser to the value required by the REBCO thin film ...

Embodiment 2

[0074] This embodiment provides a method for preparing a REBCO multilayer film on an IBAD-MgO substrate, comprising the following steps:

[0075] Step 1. Install the REBCO and STO targets prepared by high-temperature sintering into the target holder in the cavity;

[0076] Step 2, winding the IBAD-MgO base tape coated with an isolation layer in a multi-channel pulsed laser deposition system;

[0077] Step 3. Close the door of the coating system and evacuate to the required vacuum degree of 1×10 -6 , and then start the heater to raise the temperature to the temperature value required by the REBCO thin film process, the temperature is 800°C;

[0078] Step 4, feed oxygen, adjust the air pressure of the gas to the air pressure value required by the REBCO thin film coating process, and the air pressure is 300mTorr;

[0079] Step 5. Start the laser target rotation and scanning system, start the energy and frequency of the excimer laser to the value required by the REBCO thin film ...

Embodiment 3

[0094] This embodiment provides a method for preparing a REBCO multilayer film on an IBAD-MgO substrate, comprising the following steps:

[0095] Step 1. Install the REBCO and STO targets prepared by high-temperature sintering into the target holder in the cavity;

[0096] Step 2, winding the IBAD-MgO base tape coated with an isolation layer in a multi-channel pulsed laser deposition system;

[0097] Step 3. Close the door of the coating system and evacuate to the required vacuum degree of 1×10 -5 , and then start the heater to raise the temperature to the temperature value required by the REBCO thin film process, the temperature is 800°C;

[0098] Step 4, feed oxygen, adjust the air pressure of the gas to the air pressure value required by the REBCO thin film coating process, and the air pressure is 400mTorr;

[0099] Step 5. Start the laser target rotation and scanning system, start the energy and frequency of the excimer laser to the value required by the REBCO thin film ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Critical current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com