Mannan-oligosaccharide and mulberry vinegar

A technology of oligosaccharide and mulberry vinegar, which is applied to the preparation of vinegar, microorganisms, biochemical equipment and methods, etc., can solve the problems to be improved, single nutrient composition, general flavor, etc., and achieve good health care effect and high-quality flavor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

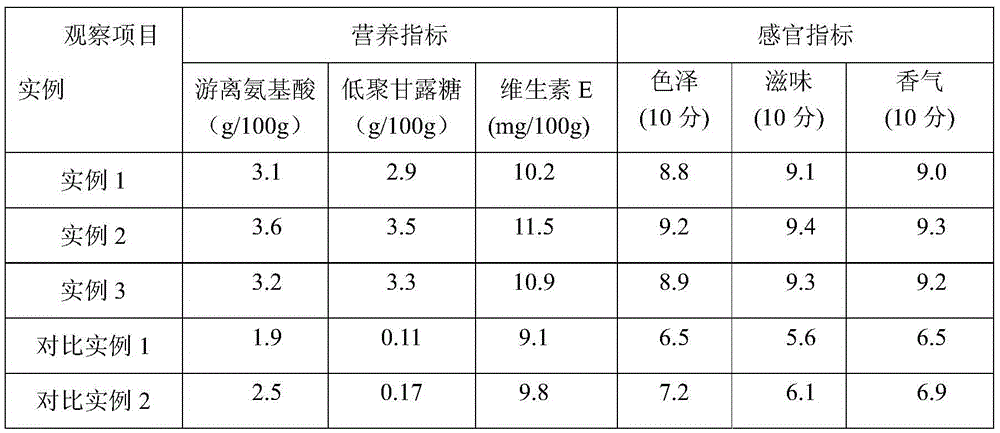

Embodiment 1

[0026] 1) Preparation of mannose oligosaccharide enzymatic hydrolysis solution: take 2 kg of konjac, 2 kg of spent yeast, 2 kg of red algae, 2 kg of mulberry leaves, 2 kg of carob endosperm, and 2 kg of guar endosperm, grind with colloid, add 10 kg of water to the slurry and mix and then add 10kg of β-mannan enzyme solution of Penicillium oxalicum to hydrolyze the mixed slurry, and enzymolyze it at 53°C for 25 hours to obtain the enzymatic hydrolysis solution of oligomannose;

[0027] Obtaining β-mannanase enzyme liquid: take Penicillium oxalicum for activation, then inoculate Penicillium oxalicum seed liquid with a volume percentage of 6% into the synthetic medium producing β-mannanase and ferment at 30°C for 60h, ferment After completion, centrifuge and filter to obtain the β-mannan enzyme solution of Penicillium oxalicum;

[0028] The composition of the synthetic medium for producing β-mannanase: 1% of glucose, 1% of urea, 1% of konjac slurry, and 0.5% of ammonium sulfate. ...

Embodiment 2

[0034] 1) Preparation of mannose oligosaccharide enzymatic hydrolysis solution: get konjac 4kg, waste yeast 4kg, red algae 4kg, mulberry leaves 4kg, carob endosperm 4kg, guar endosperm 4kg, grind with colloid, add 20kg of water to the slurry and mix and then add 20kg of β-mannan enzyme solution of Penicillium oxalicum to hydrolyze the mixed slurry, and enzymolyze at 58°C for 30h to obtain the mannose-oligosaccharide enzymatic hydrolysis solution;

[0035] Obtaining β-mannanase enzyme liquid: take Penicillium oxalicum for activation, then inoculate 10% Penicillium oxalicum seed liquid into the synthetic medium producing β-mannanase and ferment at 35°C for 72h, ferment After completion, centrifuge and filter to obtain the β-mannanase liquid of Penicillium oxalicum.

[0036] 2) Saccharification of mulberry slurry: 100 kg of mulberry is ground with colloid, then mixed with the enzymolysis solution obtained in step (1), and 0.70 g / kg of amylase with an enzyme activity of 8000 U / g i...

Embodiment 3

[0041] 1) Preparation of mannose oligosaccharide enzymatic hydrolysis solution: get konjac 3kg, waste yeast 3kg, red algae 3kg, mulberry leaves 3kg, carob endosperm 3kg, guar endosperm 3kg, grind with colloid, add 15kg of water to the slurry and mix and then add 15 kg of Penicillium oxalicum β-mannan enzyme solution to hydrolyze the mixed slurry, and enzymolyze it at 55°C for 28 hours to obtain the mannose-oligosaccharide enzymatic hydrolysis solution;

[0042] Obtaining β-mannanase enzyme liquid: take Penicillium oxalicum for activation, then inoculate Penicillium oxalicum seed liquid with a volume percentage of 8% into the synthetic medium producing β-mannanase and ferment at 32°C for 65h, ferment After completion, centrifuge and filter to obtain the β-mannanase liquid of Penicillium oxalicum.

[0043] 2) saccharification of mulberry slurry: 90kg mulberry is grinded with colloid, then mixed with the mannose-oligosaccharide enzymolysis solution obtained in step 1), and 0.55g / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com