Method for preparing GO (graphene oxide) gel with multiple stimulus responses

A multiple stimuli response, graphene gel technology, applied in the field of graphene oxide gel preparation, to achieve the effect of mild reaction conditions and less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

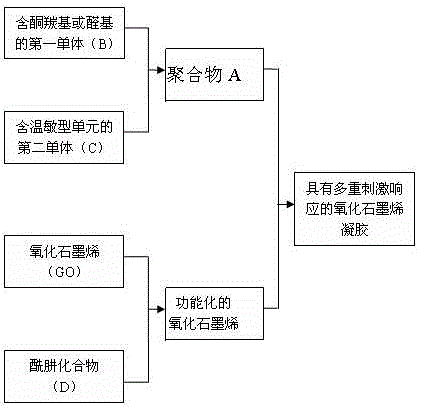

[0031] The preparation of polymer A among the present invention, the preparation of functionalized GO and the method that polymer and functionalized GO form gel are as follows:

[0032] In the reactor, add the first monomer (B) containing ketone carbonyl or aldehyde group and the second monomer C with temperature response according to a certain ratio, add a certain amount of solvent, stir and feed high-purity nitrogen 0.5- 1h, by adding a certain proportion of initiator (0.1%-10%), under the protection of nitrogen, control the temperature of the reactor at 20-80°C to react for 6-24h. After the reaction, the solvent is removed by settling and washing, and the polymer A containing ketone carbonyl or aldehyde group and temperature-sensitive structure is obtained after purification.

[0033] In the reactor, a certain concentration of GO solution and excess compound D containing hydrazide bond were reacted under alkaline conditions at 60-80°C for 6-24h, and the GO functionalized by...

Embodiment 1

[0036] In the reactor, the first monomer B (containing ketone carbonyl or aldehyde group in the monomer) and the second monomer C (containing the temperature-responsive structural unit) (the molar ratio of B to C is 3:97), dissolved In DMSO, add a certain proportion of initiator, stir and flow high-purity nitrogen for 0.5h, and react at 65°C for 24h under the protection of nitrogen. After the reaction is completed, the polymer is precipitated in ether to obtain a polymer A containing a ketone carbonyl group or an aldehyde group and a temperature-sensitive structure.

[0037] In the reactor, add excess KOH and adipic dihydrazide, a compound containing a hydrazide bond, to 0.1 mg / ml GO solution, stir and dissolve at room temperature for 10 min, and heat up to 80°C for 24 h. Suction filtration and washing yielded GO functionalized with hydrazide linkages.

[0038] In a small beaker, mix a certain amount of polymer A and GO functionalized with hydrazide bonds in a certain ratio (...

Embodiment 2

[0040]In the reactor, the first monomer B (monomer containing ketone carbonyl or aldehyde group) and the second monomer C (containing temperature-responsive structural units) (the molar ratio of B to C is 5:95) were dissolved in In DMSO, add a certain proportion of initiator, stir and flow high-purity nitrogen for 0.5h, and react at 65°C for 24h under the protection of nitrogen. After the reaction was completed, the polymer was precipitated in ether to obtain the polymer A with dual stimuli responses to pH and temperature.

[0041] In the reactor, 0.1 mg / ml GO solution was added with excess KOH and oxalylhydrazide, a compound containing a hydrazide bond, stirred and dissolved at room temperature for 10 min, and then heated to 80°C for 24 h. Suction filtration and washing yielded GO functionalized with hydrazide linkages.

[0042] In a small beaker, mix a certain amount of polymer A and GO functionalized with hydrazide bonds in a certain ratio (the ratio of ketone carbonyl to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com