Preparation method of water dispersion liquid of fluorescent polymer microsphere

A technology of fluorescent polymers and dispersions, applied in the field of coatings, can solve problems such as the decline and disappearance of fluorescent properties, and the difficulties in the practical application of fluorescent composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

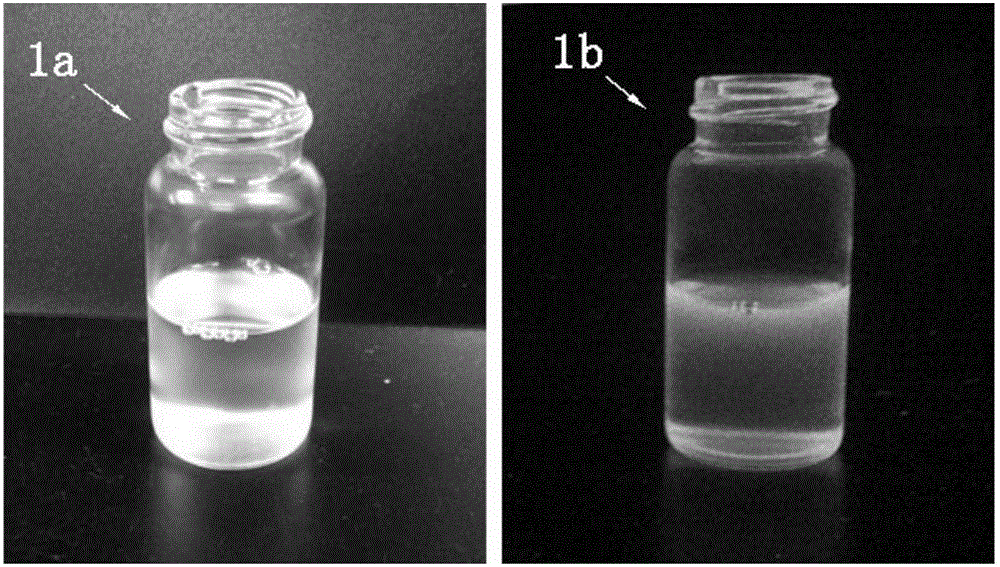

Image

Examples

Embodiment 1

[0037] The first step: dissolving tetraphenylethylene containing diacrylate groups in acrylate monomers to form an organic monomer mixture according to the following mass percentages,

[0038]

[0039] Then add an oil-soluble initiator, azobisisobutyronitrile, and the relative mass percentage of the oil-soluble initiator relative to the monomer mixture is 5%.

[0040] The second step: the organic monomer mixture obtained in the first step is dispersed in the water phase with 10% polyvinylpyrrolidone K30 in a mass ratio relative to the organic monomer mixture, and the mixture is disperse at a high speed of 5000 rpm Stir and disperse for 10 minutes to disperse evenly in the water phase.

[0041] The third step: at a stirring speed of 2000 rpm, the system was reacted at 70°C for 12 hours, and then cooled to room temperature to obtain an aqueous dispersion of fluorescent polymer microspheres. By controlling the relative ratio of the organic monomer mixture to water, Ratio, so ...

Embodiment 2

[0046] The first step: dissolving tetraphenylethylene containing diacrylate groups in acrylate monomers to form an organic monomer mixture according to the following mass percentages,

[0047]

[0048] Then add oil-soluble initiator azobisisobutyronitrile, its relative mass percentage relative to the monomer mixture is 1%.

[0049] The second step: the organic monomer mixture obtained in the first step is dispersed in the water phase with 5% polyvinylpyrrolidone K30 in a mass ratio relative to the organic monomer mixture, and the mixture is disperse at a high speed of 3000 rpm Stir and disperse for 15 minutes to disperse evenly in the water phase.

[0050] The third step: at a stirring speed of 1000 rpm, the system was reacted at 80° C. for 10 hours, and then cooled to room temperature to obtain an aqueous dispersion of fluorescent polymer microspheres, the solid content of which was 50% by weight.

Embodiment 3

[0052] The first step: dissolving tetraphenylethylene containing diacrylate groups in acrylate monomers to form an organic monomer mixture according to the following mass percentages,

[0053]

[0054] Then add oil-soluble initiator benzoyl peroxide, its relative mass percentage relative to the monomer mixture is 1%.

[0055]The second step: the organic monomer mixture obtained in the first step is dispersed in the water phase with 1% polyvinylpyrrolidone K90 in a mass ratio of 1% relative to the organic monomer mixture. Stir and disperse for 30 minutes to disperse evenly in the water phase.

[0056] The third step: at a stirring speed of 500 rpm, the system was reacted at 90° C. for 8 hours, and then cooled to room temperature to obtain an aqueous dispersion of fluorescent polymer microspheres with a solid content of 25% by weight.

[0057] Figure 4 Fluorescence spectra 1, 2, and 3 of the aqueous dispersions of fluorescent polymer microspheres prepared in different exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com