Novel continuous automated reaction process for preparing aminopolycarboxylic acids chelating agent

A technology of amino polycarboxylic acid and chelating agent, which is applied in the preparation of cyanide reaction, the preparation of organic compounds, organic chemistry, etc., to achieve the effect of stable quality, good quality and liberation of labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

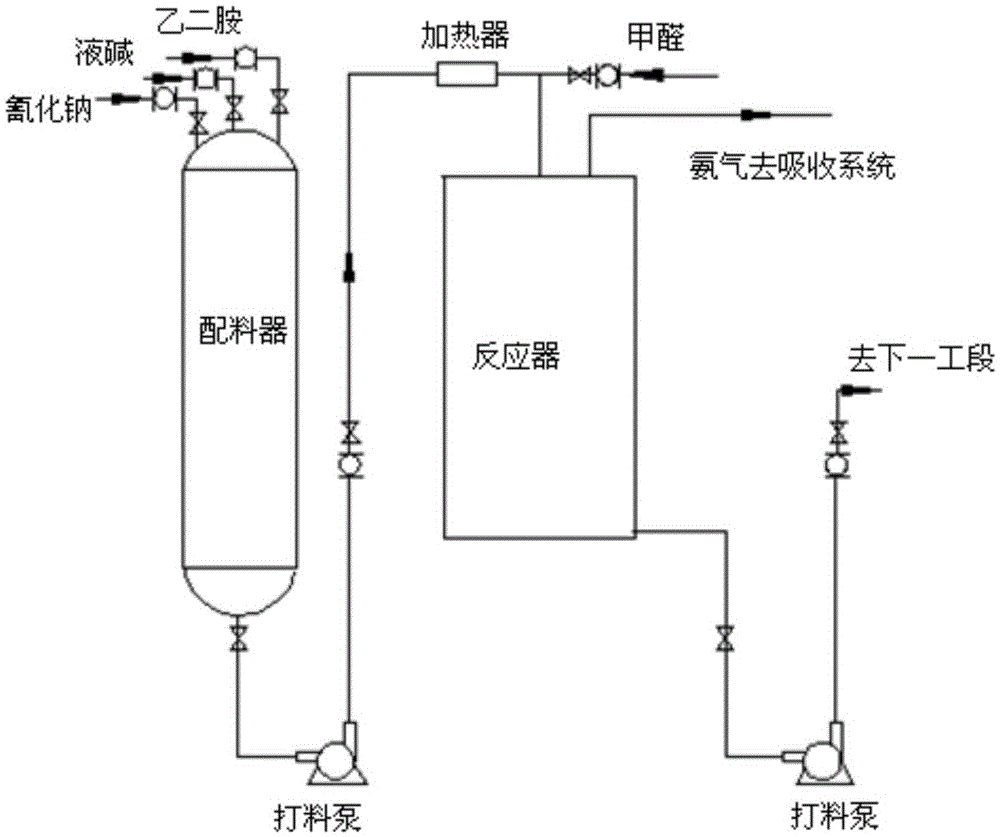

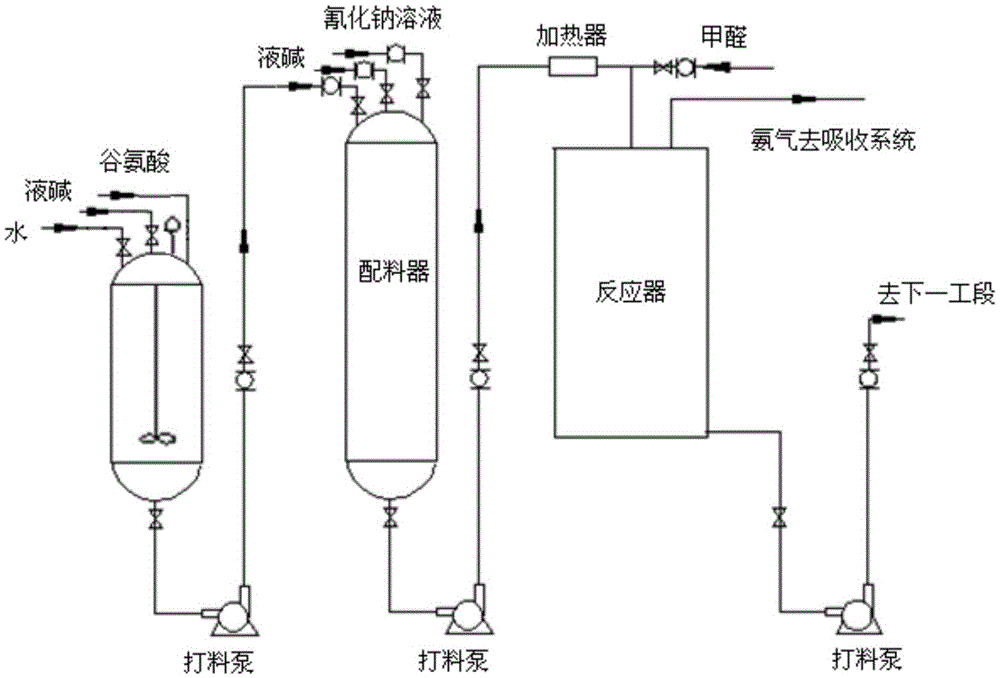

Method used

Image

Examples

Embodiment 1

[0026]The flow rate of ethylenediamine is 600kg / h, the flow rate of 30% sodium cyanide solution is 6100L / h, the flow rate of 32% sodium hydroxide solution is 300L / h, continuously mix in the mixer, the mixed material passes through, and the heater is heated to 98°C , the content is 36.5% formaldehyde, the flow rate is 3260L / h, the flow rate of the mixed material is 6770L / h, mixed at the entrance of the reactor, enters the continuous reactor, the temperature in the reactor is controlled at 102°C, and the ammonia gas is under the condition of -30KPa Escape, the reaction liquid is pumped out from the bottom of the reactor with a feeding pump, and the residual cyanide and liquid phase quality of the reaction liquid are detected. The residual cyanide is less than 100ppm, and the liquid phase content is 95%, and the operation is stable.

Embodiment 2

[0028] The flow rate of hydroxyethylethylenediamine is 600kg / h, the flow rate of 30% sodium cyanide solution is 2600L / h, and the flow rate of 32% sodium hydroxide solution is 300L / h, continuously mixed in the mixer, the mixed material passes through, and the heater Heating to 102°C, the flow rate of 36.5% formaldehyde is 1420L / h, the flow rate of the mixed material is 3400L / h, mixed at the reactor inlet, enters the continuous reactor, the temperature in the reactor is controlled at 105°C, and the ammonia gas is at -25KPa Under the condition of escape, the reaction liquid is pumped out from the bottom of the reactor with a feeding pump, and the residual cyanide and liquid phase quality of the reaction liquid are detected. The residual cyanide in the reaction liquid is less than 100ppm, the liquid phase content is 98%, and the operation is stable.

Embodiment 3

[0030] The flow rate of ethanolamine is 600kg / h, the flow rate of 30% sodium cyanide is 3020L / h, the flow rate of 32% sodium hydroxide solution is 250L / h, continuously mixed in the mixer, the mixed material passes through, the heater is heated to 105 ° C, 36.5 The flow rate of % formaldehyde is 1620L / h, the flow rate of the mixed material is 3700L / h, mixed at the reactor inlet, enters the continuous reactor, controls the temperature in the reactor at 108°C, the ammonia gas escapes under the condition of -30KPa, and the reaction solution from The bottom of the reactor is pumped out with a feeding pump, and the residual cyanide and liquid phase quality of the reaction liquid are detected. The residual cyanide in the reaction liquid is less than 100ppm, and the liquid phase content is 98.9%, and the operation is stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com