A kind of preparation method of 2,4-dichloro-5-nitrophenol

A technology of nitrophenol and nitrophenyl, which is applied in the field of organic chemistry, can solve the problems of low yield and pollution of the environment by waste acid, and achieve the effects of reducing production costs, reasonable synthesis process, and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

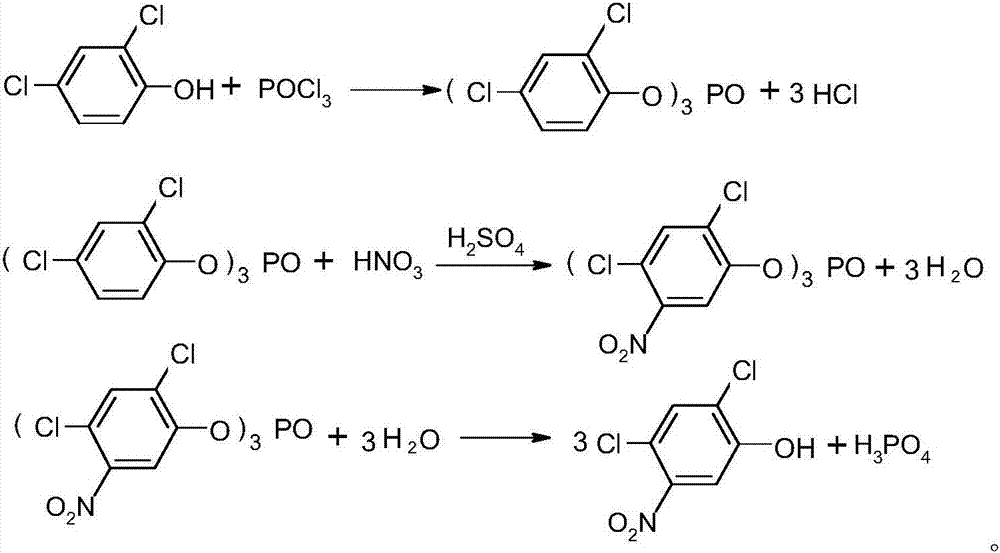

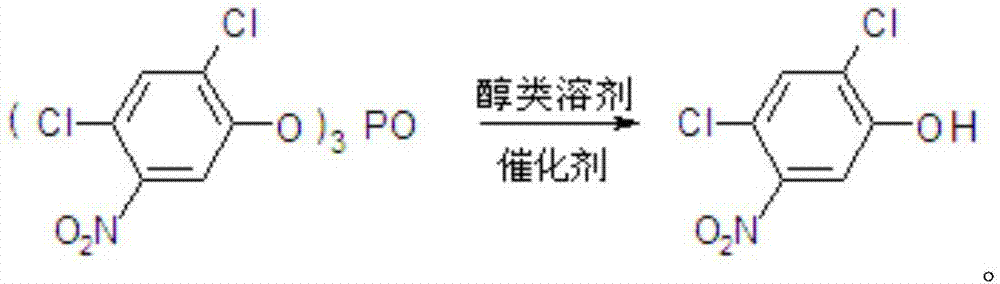

Method used

Image

Examples

Embodiment 1

[0027] In a 1000mL four-neck round bottom flask equipped with mechanical stirring, thermometer and condenser tube, add 96g methanol, 57.8g tris(2,4-dichloro-5-nitrophenyl) phosphate and 0.586g catalyst tri Lanthanum fluoromethanesulfonate, 0.72g tetrahydrofuran, stirred and gradually raised to reflux temperature, reacted for 3h, after the reaction was completed, the catalyst was separated by filtration, and after the solvent was removed, 62.7g of 2,4-dichloro-5-nitrophenol was obtained , content 98.0%, yield 98.5%.

Embodiment 2

[0029] In a 1000mL four-neck round bottom flask equipped with mechanical stirring, thermometer and condenser tube, add 192g methanol, 57.8g tris(2,4-dichloro-5-nitrophenyl) phosphate and 2.93g catalyst tri Lanthanum fluoromethanesulfonate, 1.8g tetrahydrofuran, stirred and gradually heated to reflux temperature, reacted for 5h, after the reaction was completed, the catalyst was separated by filtration, and after the solvent was removed, 62.8g of 2,4-dichloro-5-nitrophenol was obtained , content 98.3%, yield 99.0%.

Embodiment 3

[0031] In a 1000mL four-neck round bottom flask equipped with mechanical stirring, thermometer and condenser tube, add 288g methanol, 57.8g tris(2,4-dichloro-5-nitrophenyl) phosphate and 5.86g catalyst tri Lanthanum fluoromethanesulfonate, 3.6g tetrahydrofuran, stirred and gradually heated to reflux temperature, reacted for 7 hours, after the reaction was completed, the catalyst was separated by filtration, and after the solvent was removed, 63.2g of 2,4-dichloro-5-nitrophenol was obtained , content 98.5%, yield 99.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com