A constructing method of an autotrophic denitrification system for low-concentration ammonia nitrogen sewage

A low-concentration ammonia nitrogen and autotrophic denitrification technology, applied in the field of sewage biological treatment, can solve the problems of short process flow, low energy consumption, low investment and operation costs, and achieve short process flow, low energy consumption, low investment and operation low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following will further describe in detail in conjunction with the embodiments:

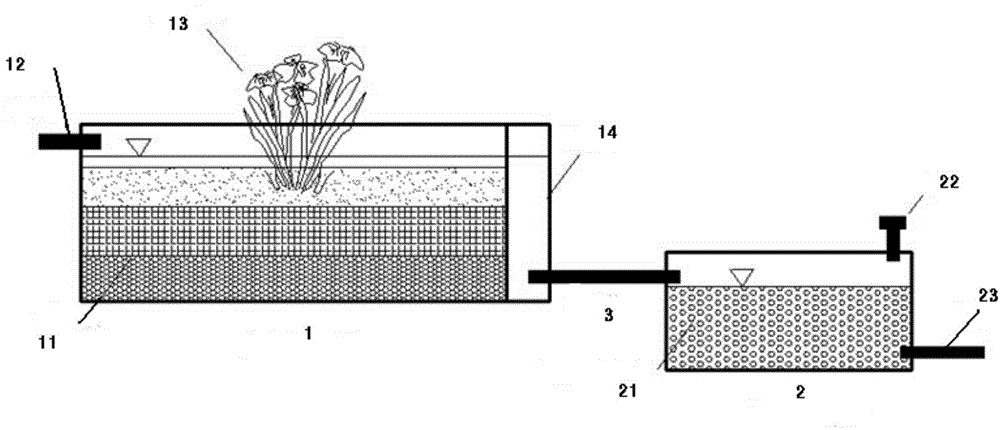

[0020] See figure 1 , The deep autotrophic denitrification treatment system of wastewater treatment plant tail water is composed of a sequential batch constructed wetland 1 and an anaerobic biofilm reactor 2 connected by a water collection pipe 3.

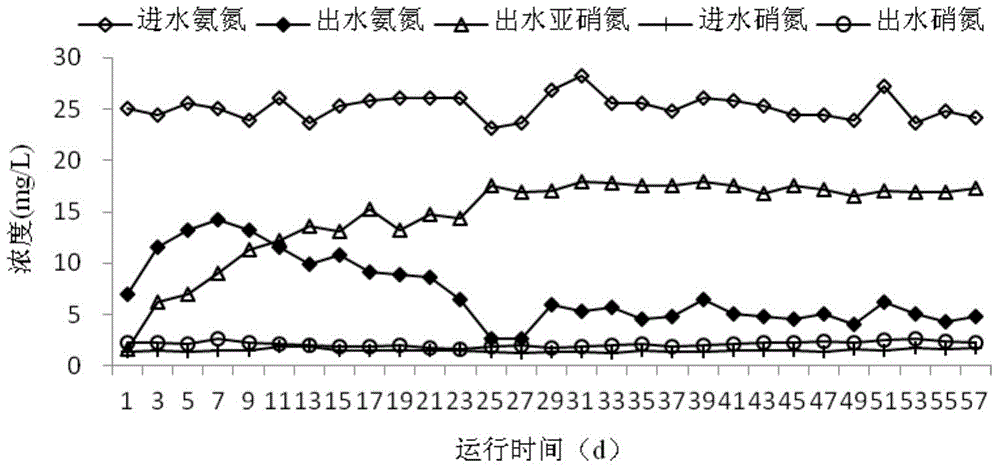

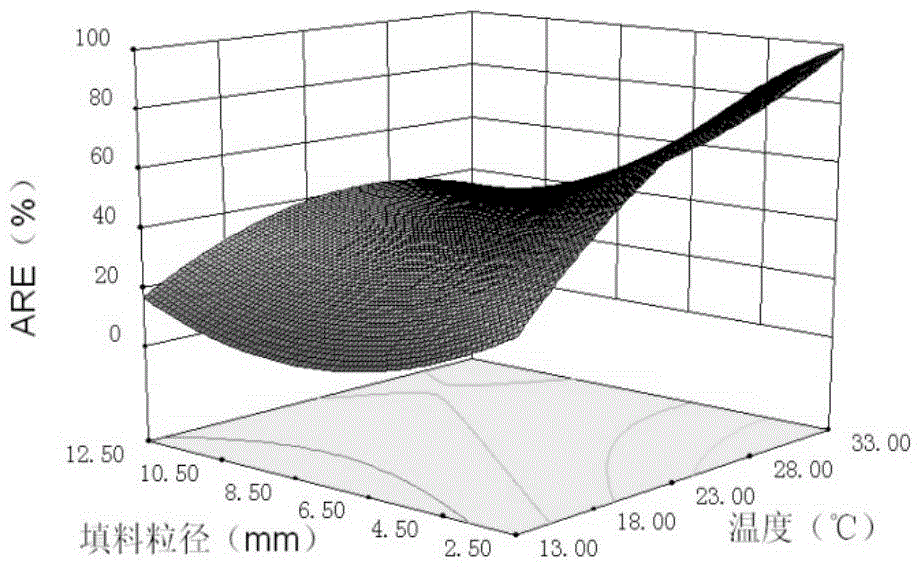

[0021] Sequential batch constructed wetland 1 has a built-in gravel filler 11 with a particle size of 2.0mm~10mm, the thickness of the gravel filler layer and effective water depth is 0.5~1m, planting of aquatic plants 13, and a water inlet pipe 12 at the front end of the sequential batch constructed wetland 1 In the catchment area 14, at a temperature of 15℃~30℃, the periodic operating conditions of the reactor are: water inlet 0.25~0.5h→reaction 12~18h→discharge 0.25~0.5h→discharge and leave for 6~10h. Constructed a short-cut nitrification system with low ammonia nitrogen concentration, which can make the artificial wetland effluent NO 2 - -N / N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com