Crab stick sealing device

A packaging device and technology of crab meat sticks, which are applied in the direction of packaging material feeding devices, packaging, and meat packaging, etc., can solve the problems of wasting raw materials, films and crab sticks, easy deviation, waste of manpower and material resources, etc., to save production costs and reduce The effect of production process and simplification of production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

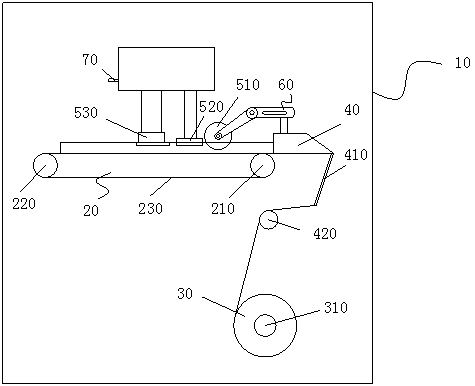

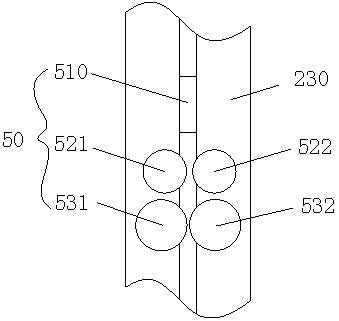

[0027] Such as figure 1 As shown, a kind of crab meat packaging device comprises a frame 10 and a conveying mechanism 20 installed on the frame 10, the conveying mechanism 20 includes a driving roller 210, a driven roller 220 and a conveyor belt 230, and the driving roller 210 is driven by the conveyor belt 230 from The moving roller 220 rotates;

[0028] The frame below the conveyor belt 230 is provided with a fixed shaft 310, and the fixed shaft 310 is sleeved with a film reel 30 that wraps the film of the crab meat stick, and the film reel 30 can freely rotate on the fixed shaft 310;

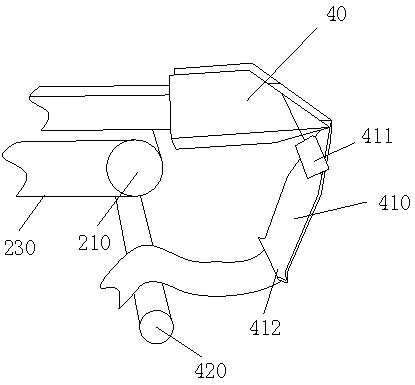

[0029] Frame 10 is provided with film folding groove 40 close to conveyor belt 230 one end, as figure 2 As shown, one end of the film folding groove 40 is arranged obliquely, and a piece of flat film conveyed from the film roll reel 30 is folded into a U-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com