Split-type multifunctional deep hole drilling machine

A deep hole drilling machine, multi-functional technology, applied in the direction of boring/drilling, drilling/drilling equipment, large fixed members, etc., can solve problems such as high special hardness, small adjustment range of adjustment center height, complex process, etc. , to achieve the effect of high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

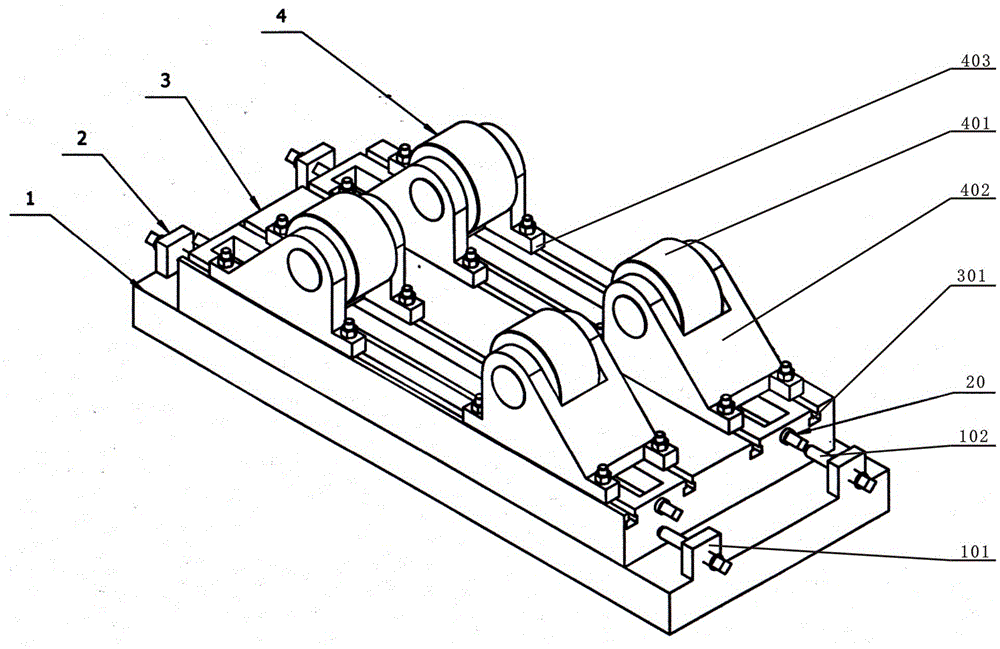

Image

Examples

Embodiment Construction

[0029] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

[0030] A split-type multifunctional deep hole drilling machine, including a mechanical power part, an adjustable workbench for heavy workpieces, a retractable correction bridge 13, an internal chip removal hydraulic part and an electrical part;

[0031] Described mechanical power part comprises head of a bed, bed 18, power head 11, transmission case 14, gearbox 12 center shock mounts 9 and motor part; The upper end face of bed 18 is provided with sliding workbench; Motor part connects electric part The head of the bed is set on the sliding workbench away from one end of the heavy-duty adjustable workbench, and the other end of the sliding workbench is also provided with a chip oil tank 8; the inside of the head of the bed is provided with a gearbox 12, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com