A method for cleaning the electric corrosion layer of magnetic steel materials

A technology of electric machining and electro-etching layer, which is applied in the field of cleaning, can solve the problems of low processing efficiency, low pass rate, small magnetic steel, etc., and achieve the effect of improved cleaning quality, high processing efficiency and stable cleaning quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

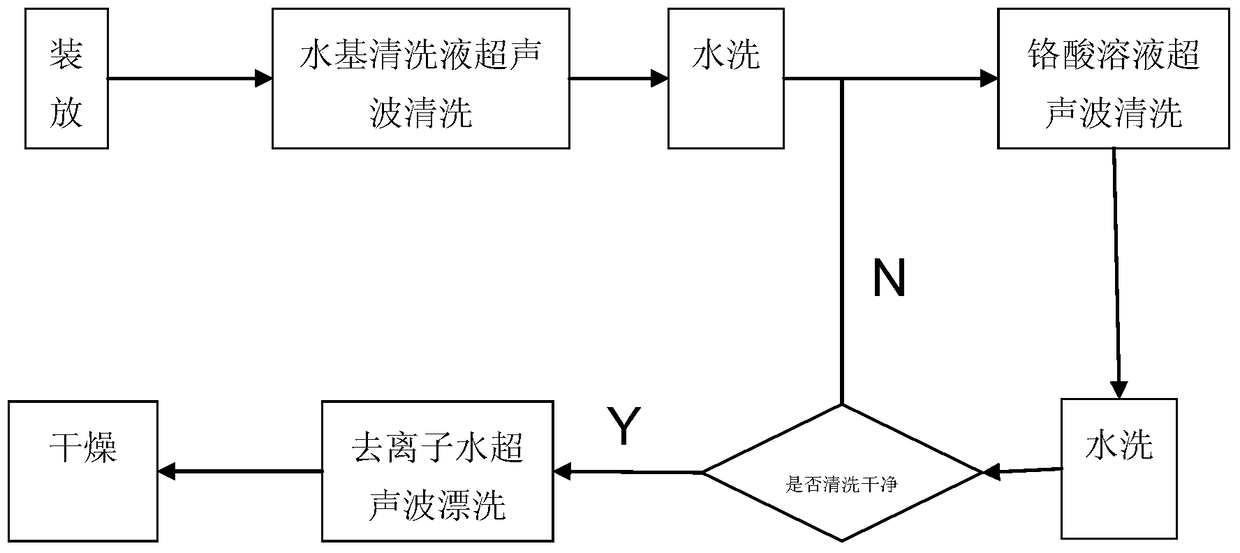

[0017] Below in conjunction with accompanying drawing, the present invention will be further described:

[0018] The main purpose of the present invention is to completely remove the black electro-corrosion layer produced by electrical processing of magnetic steel materials to meet the assembly requirements. The present invention selects suitable cleaning solutions and cleaning parameters to realize the complete removal of electro-corrosion products on the surface of parts. The process refers to figure 1 The specific process is as follows:

[0019] Step 1: LCX-52 water-based cleaning ultrasonic cleaning

[0020] Carefully store the magnets flat in the flat-bottomed plastic box, parts must not be stacked. Pour (10-30) g / L LCX-52 water-based cleaning solution into a flat-bottomed plastic box, clean it in 28-32KHz ultrasonic wave for 10 minutes, reverse the magnetic steel and clean it again, and rinse it with tap water after cleaning

[0021] Step 2: Ultrasonic cleaning with ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com