Silicon-supported ionic liquid catalyst

An ionic liquid, imidazole ionic liquid technology, applied in physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, organic chemistry, etc., can solve the problem of insufficient catalyst efficiency and selectivity, short cycle life and other problems, to achieve the effects of easy control, increased cycle times, and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

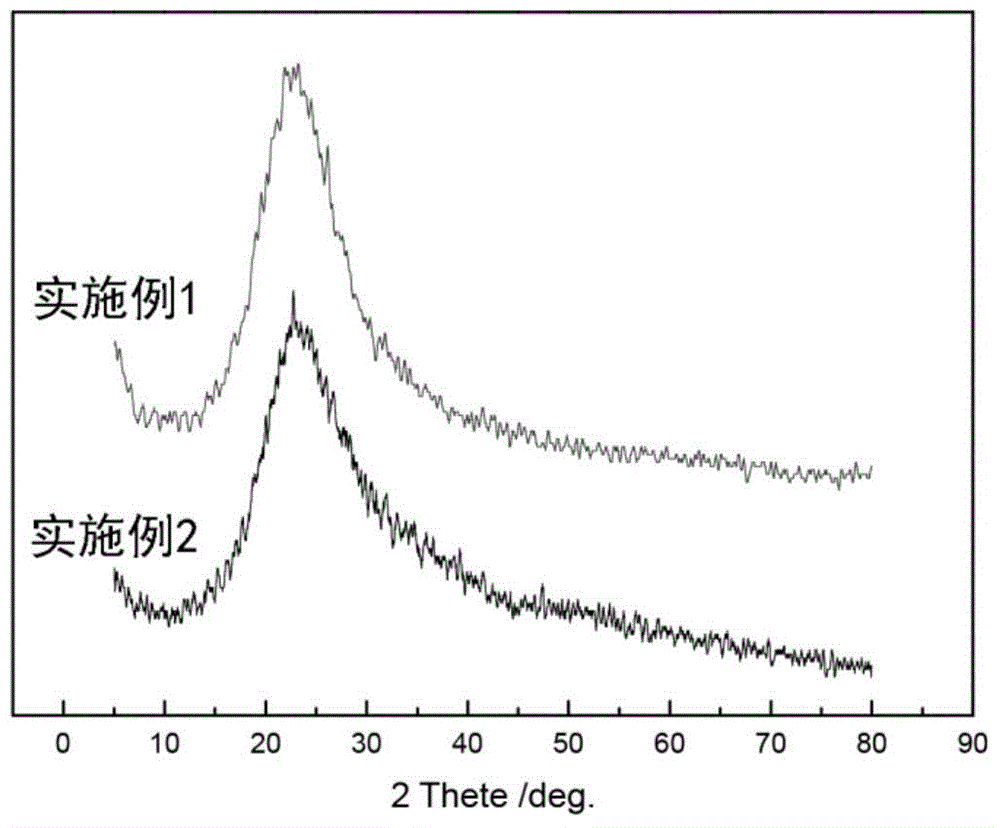

Embodiment 1

[0050] Mix 24mL of N-methylimidazole and 20mL of 2-chloroethanol into a round-bottomed flask with a reflux condenser, under nitrogen protection, stir in a water bath at 80°C for 24h, stop the reaction, and dilute the obtained light yellow liquid with diethyl ether repeatedly Extracted 4 times, placed in a vacuum drying oven at 80°C, -0.09MPa and distilled under reduced pressure for 12h to obtain 1-(2-hydroxyethyl)-3-methylchloroimidazolium ionic liquid [HeMIM]Cl with a yield of 94 %.

[0051] Add 12mL tetraethyl orthosilicate (TEOS) and 8mL ethanol into a 100mL round-bottomed flask, place in a heating magnetic stirrer, mix and heat to 60°C. When the mixed system became clear, the ionic liquid [HeMIM]Cl was added (the molar ratio of [HeMIM]Cl to TEOS was 2:1). Under the action of stirring, it gradually becomes an oil bead suspension system. After continuing to react for 5 hours, start to add 24mL of hydrochloric acid dropwise. The color of the system gradually becomes lighter,...

Embodiment 2

[0054] Put 9.63mL of N-methylimidazole in a 100ml three-neck flask, add 9.5g of chloroacetic acid in three batches, and after the chloroacetic acid is completely dissolved, place the reaction in a water bath at 70°C for 10 hours to obtain a light yellow liquid. Pour it into a beaker and wash it repeatedly with ether for 3 times, put it in a vacuum drying oven at 80°C, -0.09MPa and distill for 12 hours under reduced pressure to obtain 1-carboxyethyl-3-methylimidazolium chloride ionic liquid [CeMIM]Cl, Yield 91%.

[0055] Add 12mL tetraethyl orthosilicate (TEOS) and 8mL ethanol into a 100mL round-bottomed flask, place in a heating magnetic stirrer, mix and heat to 60°C. When the mixed system became clear, the ionic liquid [CeMIM]Cl was added (the molar ratio of [CeMIM]Cl to TEOS was 2:1), and the oily bead-like liquid began to form, and white foam appeared after 1.5 hours, and a small part of it solidified after 100 minutes. After 4 hours of reaction, 24mL of HCl was added drop...

Embodiment 3

[0058] In the same equipment used in Example 2, under the same conditions, just change the amount of ionic liquid added, the amount of [CeMIM]Cl and TEOS and the molar ratio is 3:1, the catalyst is supported silicon type chloride 1-carboxylate Ethyl-3-methylimidazolium ionic liquid [CeMIM]Cl-Si, its catalyzed reaction nearly 40min observes that the carbon dioxide mass flow count value does not change, after the completion of the reaction, the purity of the ethylene carbonate product is 98.4%, and the calculated epoxy The conversion of ethane was 98.1%, and the yield of ethylene carbonate was 96.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com