Mott transistor and fabrication method thereof

A transistor and Mott technology, applied in the field of Mott transistors and preparation, can solve the problems of thermal stability of leakage and poor stability of Mott transistors, and achieve the effect of solving leakage and poor thermal stability and ensuring stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

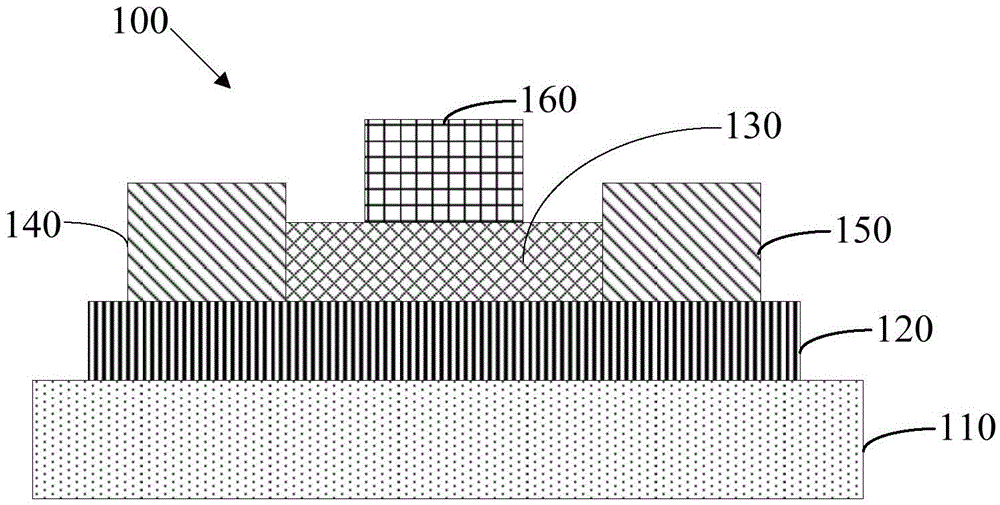

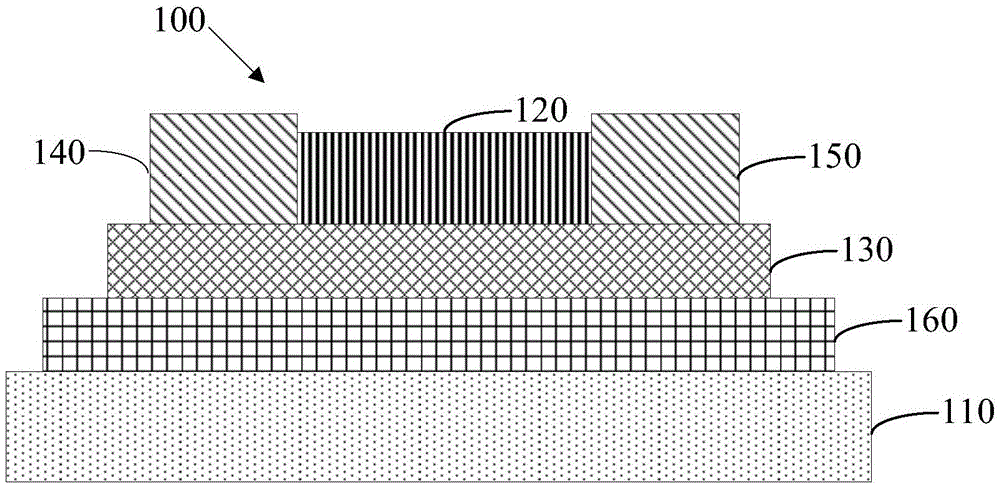

[0046] Specifically, the structure of the Mott transistor of the present invention can be either a top-gate structure or a bottom-gate structure. Therefore, the Mott transistor preparation method provided by the present invention specifically includes the following steps:

[0047] First, through step S100, the gate electrode 160 is prepared on the surface of the substrate 110 by a coating process, and then the gate dielectric layer 130 and the channel layer 120 are sequentially prepared on the surface of the gate electrode 160, and then through step S200, A source electrode 140 and a drain electrode 150 are prepared on the surface of the gate dielectric layer 130 covered by the gate dielectric layer 120 . In this way, the preparation of the bottom-gate Mott transistor 100 can be completed.

[0048] Or, first, through step S100', the channel layer 120 and the gate dielectric layer 130 are sequentially prepared on the surface of the substrate 110 by using a coating process, and...

Embodiment 1

[0054] This example provides figure 1 A fabrication method of an all-solid-state metal-insulator transition Mott (Mott) transistor 100 with a top-gate structure is shown. Wherein, the substrate 110 is thermal silicon oxide, and the gate dielectric layer 130 is silicon dioxide (SiO 2 ) film, the channel layer 120 is vanadium dioxide (VO 2 ) film, the gate 160, the source 140 and the drain 150 are Ti / Au composite films.

[0055] The manufacturing method of the all-solid-state metal-insulator transition Mott (Mott) transistor 100 of the top gate structure of the present embodiment includes the following steps:

[0056] Step 1: Clean thermal silica by ultrasonic cleaning with acetone, absolute ethanol and deionized water.

[0057] Step 2: Deposit a layer of vanadium dioxide (VO 2 ) film as the channel layer 120. Wherein, the process condition when adopting the magnetron sputtering technology to deposit the channel layer 120 is: the vacuum degree of the vacuum chamber of the m...

Embodiment 2

[0063] This embodiment also provides figure 1 A fabrication method of an all-solid-state metal-insulator transition Mott (Mott) transistor 100 with a top-gate structure is shown. Wherein, in this embodiment, the substrate 110 in the Mott transistor 100 is sapphire, and the gate dielectric layer 130 is aluminum oxide (Al 2 o 3 ) film, the channel layer 120 is a cobalt oxide (CoO) film, and the gate 160, source 140 and drain 150 are Ti / Au composite films.

[0064] The manufacturing method of the all-solid-state metal-insulator transition Mott (Mott) transistor 100 of the top gate structure of the present embodiment includes the following steps:

[0065] Step 1: Ultrasonic cleaning of clean sapphire with acetone, absolute ethanol and deionized water.

[0066] Step 2: Deposit a cobalt oxide (CoO) thin film on the sapphire as the channel layer 120 by magnetron sputtering technology.

[0067] Step 3: Deposit a Ti / Au composite film on the cobalt oxide (CoO) film as the source ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com