Novel aging treatment heat energy recycling device

A technology of heat energy recovery and aging treatment, which is applied in waste heat treatment, lighting and heating equipment, furnaces, etc., can solve the problems of heat transfer efficiency limitation of heat exchangers, long return on investment period, and impact on product quality, and achieve return on investment period Short, reduced power, high heat energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention will be described in detail below.

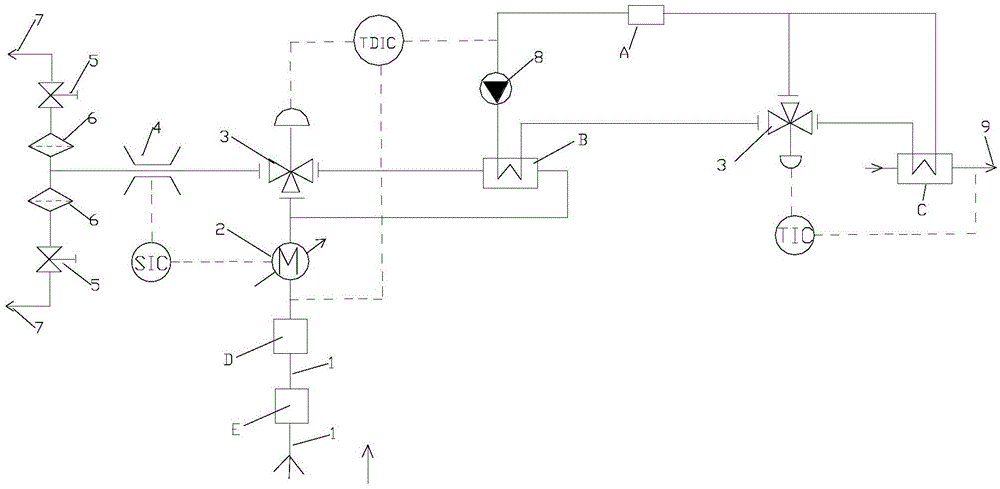

[0020] Such as figure 1 As shown, the present invention discloses a new type of heat recovery device for aging treatment, including a heat collection module, a frequency conversion motor 2, a heat preservation pipe 1, a heat pump 8, an electric three-way regulating valve 3, a manual regulating valve 5, and a multi-stage air filter 6. TDIC temperature difference control module, FIC flow control module 4. TIC temperature control module and SIC speed control module. The heat collection module includes a heat recovery module and a heat absorption and exchange module. The heat absorption and exchange module includes a heat absorption and exchange module B and a heat absorption and exchange module. Module C, the thermal energy recovery module includes thermal energy recovery module A, thermal energy recovery module D and thermal energy recovery module E. One end of the thermal energy recovery module E ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com