Polishing method for surface of metal plate

A metal plate and particle technology, used in metal processing equipment, abrasives, manufacturing tools, etc., can solve the problems of cumbersome operation, great harm to human body and environment, unsuitable for irregular parts, etc. The effect of reducing immersion and impact on people and the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This embodiment is used to illustrate the method for polishing the metal plate surface provided by the present invention

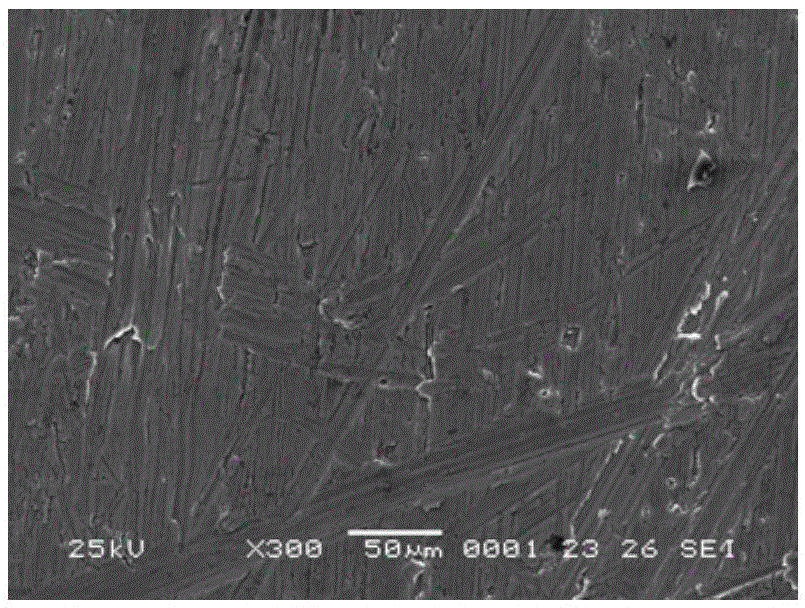

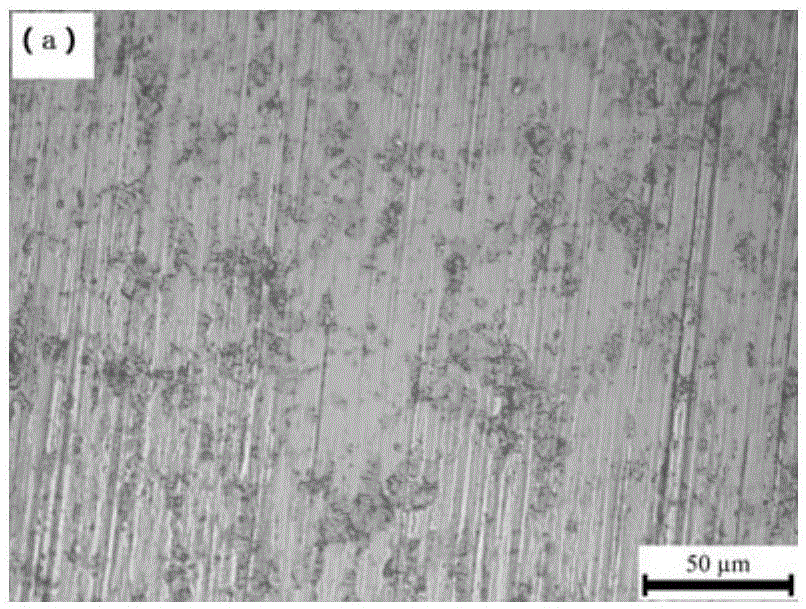

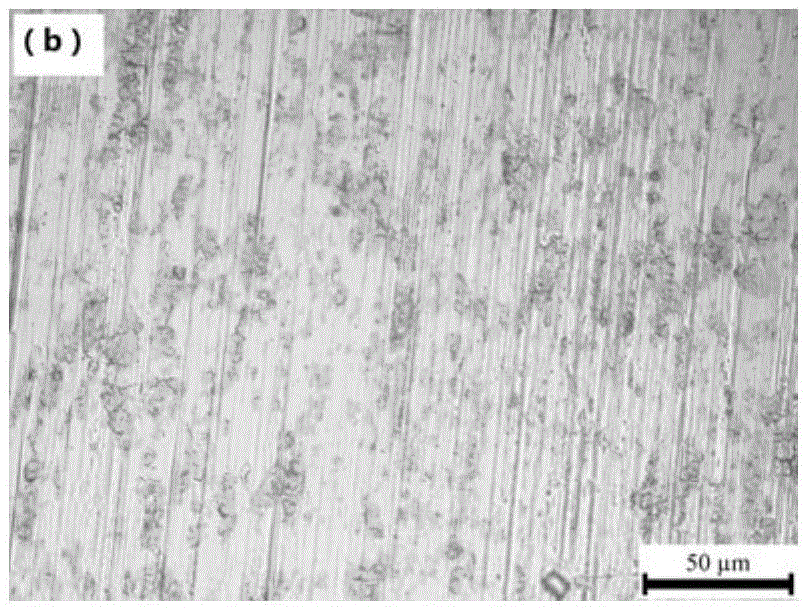

[0047] (1) Spray treatment

[0048] Put the irregular titanium plate with a thickness of 5mm into the shot blasting machine for shot blasting treatment, fill the shot blasting machine with 15% steel balls with a particle size of 0.8mm, 75% of pellets with a particle size of 0.3mm, and 10% The pellets with a particle size of 0.1mm, wherein, relative to each square meter of metal plate, the shot blasting pressure is 2MPa, and the particle density is 70kg. Among them, the blasting treatment of large-sized particles is carried out first, and then the spraying treatment of medium-sized and small-sized particles is carried out. The surface roughness of the titanium plate after treatment is determined to be between 1.0-0.8 μm.

[0049] (2) Purification treatment 1

[0050] The titanium plate after the treatment in step (1) was washed with water for 3 ti...

Embodiment 2

[0057] This embodiment is used to illustrate the method for polishing the metal plate surface provided by the present invention

[0058] (1) Spray treatment

[0059] Put the irregular titanium plate with a thickness of 8mm into the shot blasting machine for shot blasting treatment, fill the shot blasting machine with 17% steel balls with a particle size of 0.6mm, 68% with pellets with a particle size of 0.4mm, and 15% The pellets with a particle size of 0.15mm, wherein, relative to each square meter of metal plate, the shot blasting pressure is 3MPa, and the particle density is 65kg. Among them, the blasting treatment of large-sized particles is carried out first, and then the spraying treatment of medium-sized and small-sized particles is carried out. The surface roughness of the titanium plate after treatment is determined to be between 1.2-1.0 μm.

[0060] (2) Purification treatment 1

[0061] The titanium plate after step (1) was washed with water for 3 times, wherein t...

Embodiment 3

[0066] This embodiment is used to illustrate the method for polishing the metal plate surface provided by the present invention

[0067] (1) Spray treatment

[0068] Put the irregular titanium plate with a thickness of 2mm into the shot blasting machine for shot blasting treatment, fill the shot blasting machine with 15% steel balls with a particle size of 0.65mm, 70% of pellets with a particle size of 0.2mm, and 15% The pellets with a particle size of 0.1mm, the shot blasting pressure is 1.5MPa, and the particle density is 70kg per square meter of metal plate. Among them, the blasting treatment of large-sized particles is carried out first, and then the spraying treatment of medium-sized and small-sized particles is carried out. The surface roughness of the titanium plate after treatment is determined to be between 1.3-1.1 μm.

[0069] (2) Purification treatment 1

[0070] The titanium plate after step (1) was washed with water for 3 times, wherein the first and third time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com