Air-conveying type ultrasonic wave micron-grade dry fog dust suppression system and method

An ultrasonic, micron-scale technology, applied in separation methods, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve problems such as non-flammability, short service life, and inability to ensure efficient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

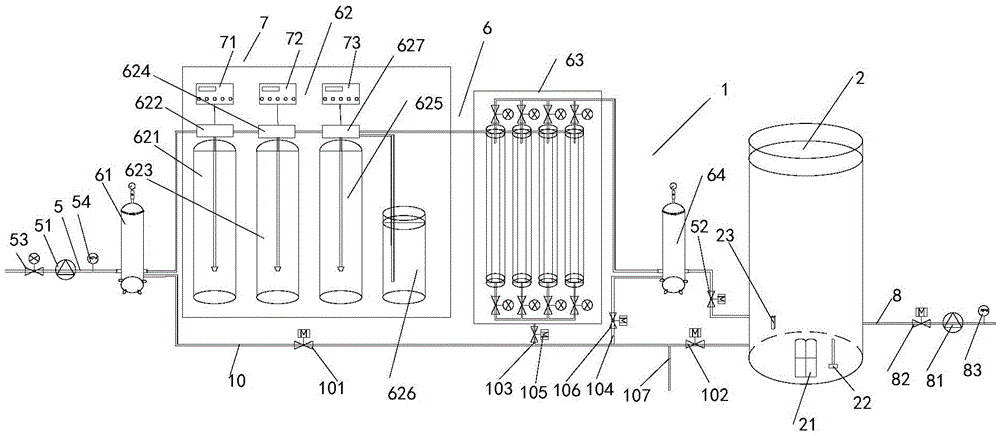

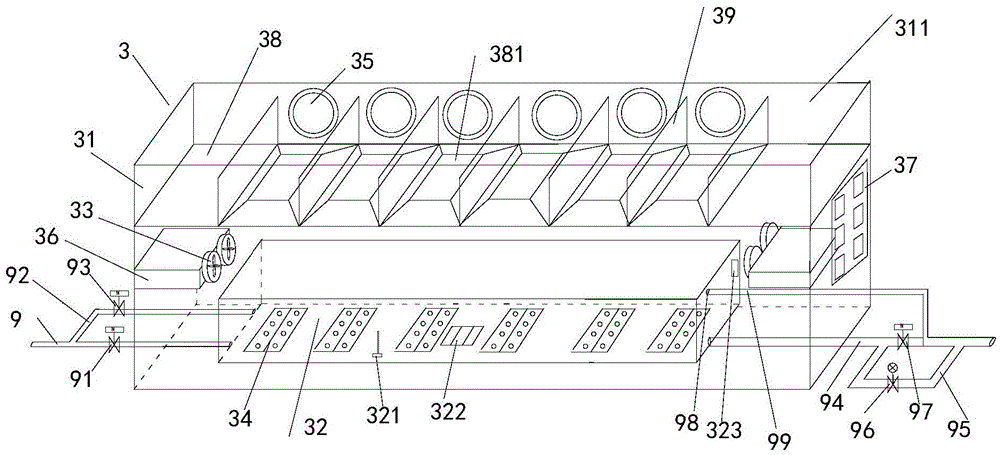

[0053] Embodiment 1. An air-driven ultrasonic micron-level dry fog dust suppression system. Combine below Figure 1 to Figure 3 The system provided in this embodiment will be described in detail.

[0054] see Figure 1 to Figure 3 , an air-driven ultrasonic micron-scale dry fog and dust suppression system provided in this embodiment includes a water filtering and softening device 1, a water storage tank 2, at least one dry fog and dust suppressing device 3, and a local controller 4; the water filtering and softening The device 1 includes a tap water inlet pipe 5, a filtering and softening device 6, and a filtering and softening device controller 7. The tap water inlet pipe 5 communicates with one side of the lower end of the water storage tank 2 through the filtering and softening device 6, and the tap water The water inlet of the water inlet pipe 5 is provided with a tap water booster pump 51, and one end connected with the water storage tank 2 is provided with a filtered w...

Embodiment 2

[0080] Embodiment 2. An air-driven ultrasonic micron-level dry fog dust suppression method. Combine below Figure 1 to Figure 3 The method provided in this embodiment will be described in detail.

[0081] see Figure 1 to Figure 3 , a kind of air-driven ultrasonic micron-scale dry fog dust suppression method provided by the present embodiment, said method comprises the following steps:

[0082] S1. When the water storage level gauge 23 detects that the height of the water in the water storage tank 2 is lower than the set lower limit value of the water storage tank water level, it sends a signal to the local controller 4, and the local control The device 4 controls the opening of the filtered water inlet solenoid valve 52, and at the same time controls the filter softening device controller 7 to start working, tap water enters the tap water inlet pipeline 5 passing through the filter softening device 6, and the filter softening device The device 6 filters and softens the tap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com