Positive/negative electrode material for high-performance asymmetric capacitor and preparation method for positive/negative electrode material

An asymmetric capacitor technology, applied in the field of nanocomposite preparation, can solve the problems of low utilization rate of energy storage materials, narrow capacitor operating voltage, sacrificing power density, etc., and achieve excellent electrochemical performance, reliable adsorption, and easy reagents. the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

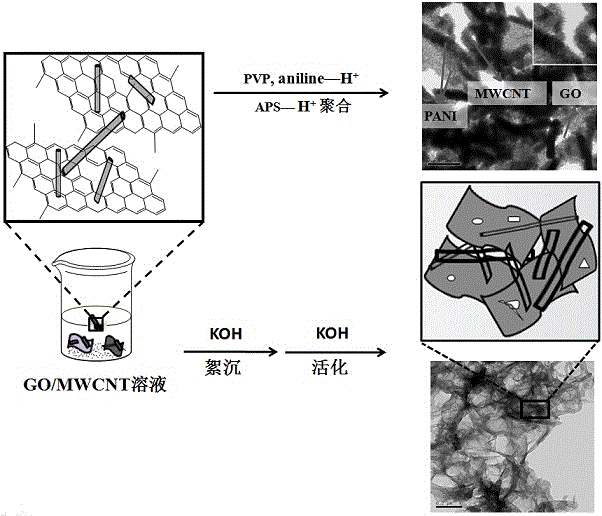

[0030] (1) Preparation of GO / MWCNT mixed solution: Disperse 50 mg of GO / MWCNT mixture with a mass ratio of 3:2 in 50 mL of deionized water, stir for 12 hours, then gently sonicate for 10 minutes to promote uniform dispersion and prevent GO fragmentation, and then 2000r / min low-speed centrifugation to obtain the clarified solution to obtain a GO / MWCNT mixed solution;

[0031] (2) Preparation of positive electrode material—PANI / GO / MWCNT ternary composite material: Add 0.1 g of nonionic surfactant PVP (polyvinylpyrrolidone (polyvinylpyrrolidone) PVP for short) or OP to the mixed solution obtained in step (1). -10, stir to dissolve to obtain the base solution; then dissolve 0.5mL of aniline monomer in 25mL of 1M sulfuric acid, slowly add to the base solution to obtain a growth solution; weigh 1.25g of ammonium persulfate and dissolve in 25mL of 1M sulfuric acid, transfer to In a liquid funnel, add 2-4 drops per second to the growth solution while maintaining the temperature at 0-...

Embodiment 2

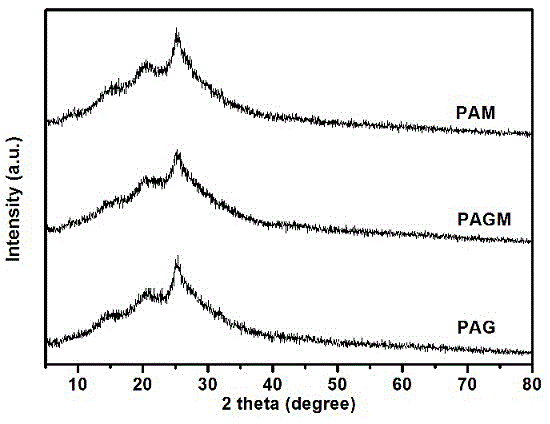

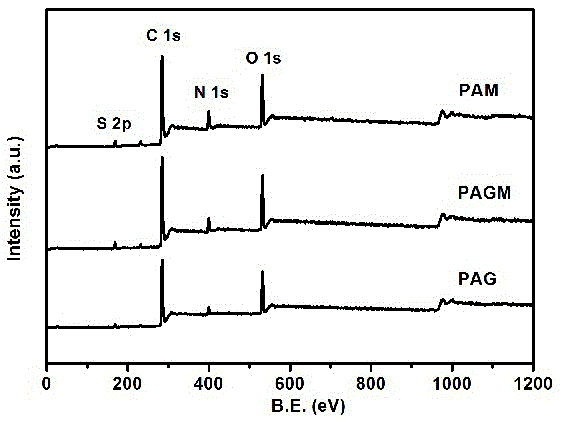

[0034] According to the reaction steps and process of Example 1, only the mixed solution of GO / MWCNT was changed to pure GO solution to obtain the composite material PAG. The XRD and XPS of the positive electrode material PAG obtained in this example are as follows: figure 2 , as shown in 3, is not much different from PAGM, indicating a similar structure and elemental composition. Its electrochemical characterization as Figure 4 ,5,6 shows that it exhibits a similar curve structure with PAGM, which proves the above, but because of the lack of MWCNT to provide better conductivity, its electrochemical performance is worse than that of PAGM.

Embodiment 3

[0036] According to the reaction steps and process of Example 1, only the mixed solution of GO / MWCNT was changed to pure MWCNT solution to obtain the composite material PAM. The XRD and XPS of the positive electrode material PAG obtained in this example are as follows: figure 2 , as shown in 3, is not much different from PAGM, indicating a similar structure and elemental composition. Its electrochemical characterization as Figure 4 ,5,6 shows that it exhibits a similar curve structure with PAGM, which proves the above, but because of the lack of GO to provide a large specific surface area, its electrochemical performance is worse than that of PAGM.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com