Operation mode and structure of a heat circulation heat pump drying device

A technology of heat pump drying and drying equipment, which is applied in the direction of drying, drying machine, and drying gas arrangement, etc., which can solve the problems of poor water removal effect, lower energy efficiency ratio of the heat pump system, and slow temperature rise of the air in the oven. Effects of improved SMER, high COP value, and shortened drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

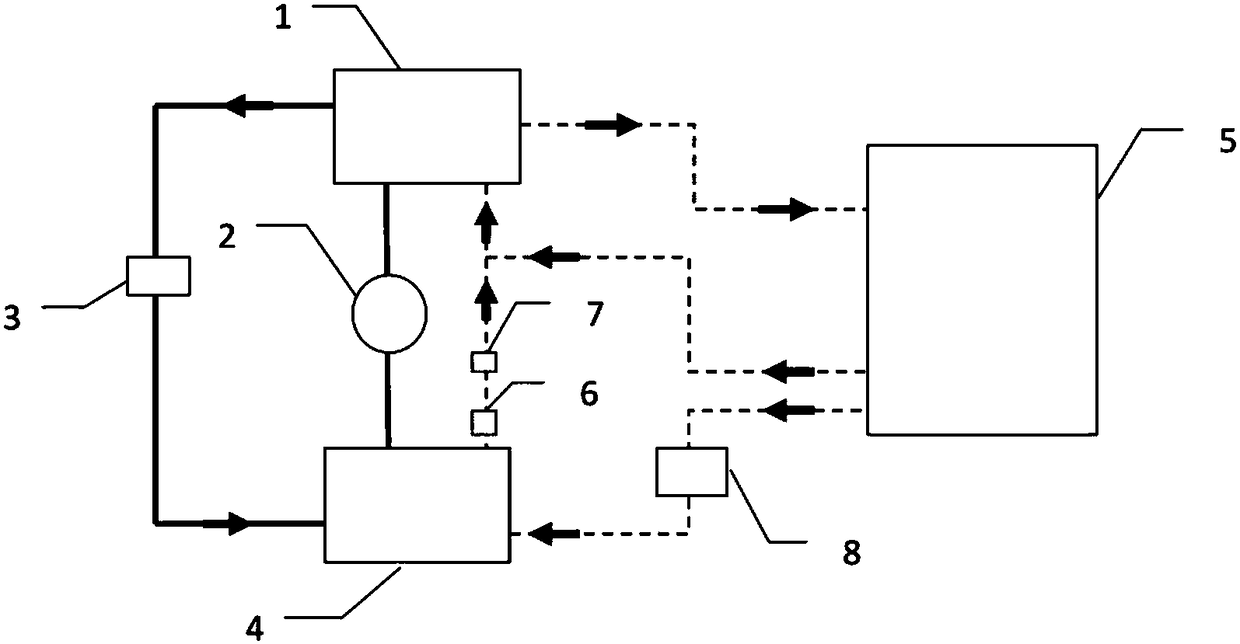

[0032] Embodiment 1: Frequency conversion heat pump clothes dryer.

[0033] The heat pump system of this embodiment is a frequency conversion heat pump system, including a heat pump system composed of a compressor 2, a throttle valve 3, a condenser 1, an evaporator 4, a fan, etc., and an oven box, etc. An adjustable damper 8 is installed on the heat recovery air duct in the device, and an exhaust pipe 6 and an air suction pipe 7 are also included. In the initial stage of device operation, it is in the heating mode. The damper can be adjusted so that the inlet and outlet of the heat recovery air duct are connected to the atmosphere and isolated from the inner cavity of the oven. There is a fan to make the atmospheric air flow in from the inlet of the air duct and flow through it. After the evaporator is emptied into the atmosphere from the air outlet of the air duct, the heat absorbed by the evaporator is released by the condenser 1 and the condensing fan to the inner cavity of...

Embodiment 2

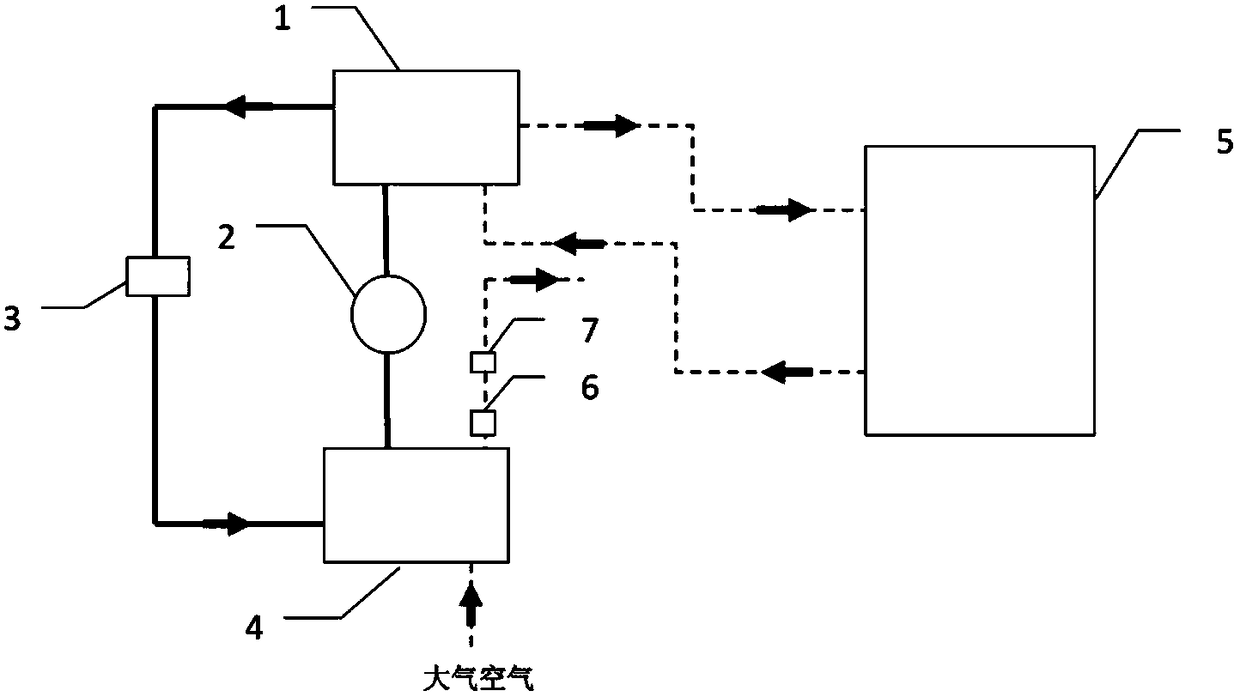

[0034] Embodiment 2. Drying device for dual heat pump system

[0035] The structure of this embodiment is similar to that of Embodiment 1, the difference is: A. There are two independent heat pump systems, and the evaporators of the two heat pump systems are installed in series upstream and downstream of the heat recovery air duct. B. The device is equipped with an exhaust port leading to the atmosphere with a fan and an air intake pipe leading to the atmosphere, and the exhaust port is upstream of the air intake pipe. C. A sensible heat exchanger is installed in the device.

[0036] In the initial stage of device operation, the adjustable damper is controlled so that the inlet and outlet of the heat recovery air duct are connected to the atmosphere and isolated from the inner cavity of the oven, and there is a fan to allow atmospheric air to flow in from the inlet of the air duct and flow through the evaporator Afterwards, it is emptied from the air outlet of the air duct in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com