Raw material for high-speed growth of silicon carbide crystals and silicon carbide crystal growing method

A technology of silicon carbide and raw materials, applied in crystal growth, single crystal growth, single crystal growth, etc., can solve problems such as unfavorable high-speed growth of silicon carbide crystals, and achieve the effect of increasing the amount of sublimation, increasing the speed of sublimation, and increasing the concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

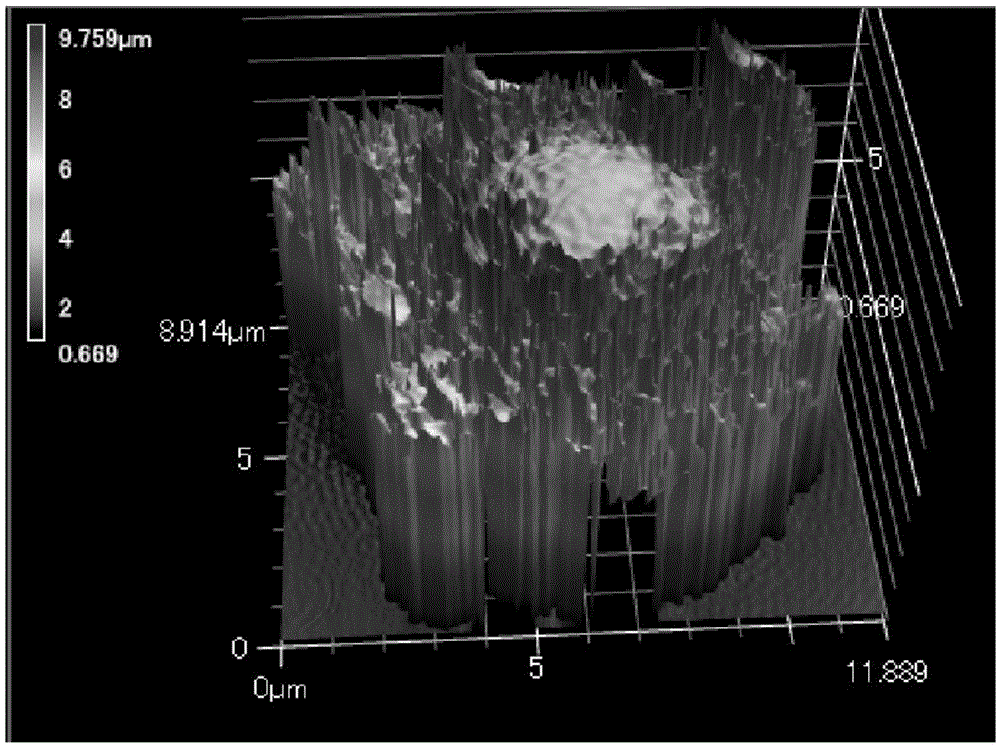

[0042] Metal silicon powder with a size of 1-10μm is supplied to the furnace at a temperature of 2500°C at a rate of 200g per minute, and carbon source gas and argon are also supplied to the furnace at a rate of 200L per minute, and the furnace is controlled The pressure is maintained at 10000Pa. After sufficient reaction, the corresponding silicon carbide powder is obtained. The obtained silicon carbide powder is treated with a mixture of hydrofluoric acid and nitric acid to remove the remaining silicon components. After drying, the corresponding silicon carbide powder is obtained. Among them, the reaction efficiency of silicon carbide is 20%, the particle size of silicon carbide can be adjusted according to actual needs, and the surface morphology of silicon carbide powder is as follows: figure 1 shown.

Embodiment 2

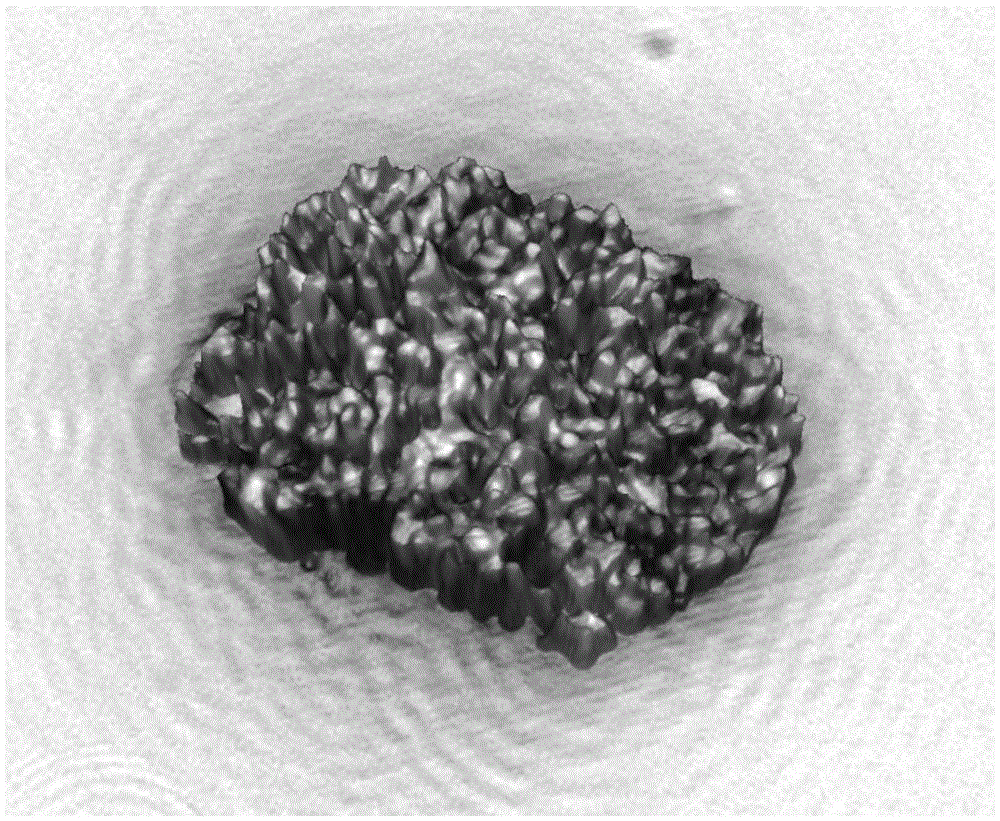

[0044] Supply metal silicon powder with a size of 1-10 μm into the furnace at a temperature of 2500 ° C at a rate of 5 g per minute, and supply carbon source gas and argon gas into the furnace at a rate of 10 L per minute, and control the temperature of the furnace. The pressure is maintained at 1000Pa. After sufficient reaction, the corresponding silicon carbide powder is obtained. The obtained silicon carbide powder is treated with a mixture of hydrofluoric acid and nitric acid to remove the remaining silicon components. After drying, the corresponding silicon carbide powder is obtained. Among them, the reaction efficiency of silicon carbide is 90%, the particle size of silicon carbide can be adjusted according to the actual situation, and the surface morphology of silicon carbide powder is as follows: figure 2 shown.

Embodiment 3

[0046] Supply metal silicon powder with a size of 1-10μm into the furnace at a temperature of 2500°C at a rate of 10g per minute, and supply carbon source gas and argon gas into the furnace at a rate of 50L per minute, and control the furnace The pressure is maintained at 2000Pa. After sufficient reaction, the corresponding silicon carbide powder is obtained. The obtained silicon carbide powder is treated with a mixture of hydrofluoric acid and nitric acid to remove the remaining silicon components. After drying, the corresponding silicon carbide powder is obtained. Among them, the reaction efficiency of silicon carbide is 70%. The particle size of silicon carbide can be adjusted according to the actual situation. The surface morphology of silicon carbide powder is as follows: image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com