Vapor deposition source for vacuum vapor deposition apparatus

An evaporation source and evaporation technology, applied in vacuum evaporation coating, lighting devices, light sources, etc., can solve the problems of low evaporation rate, small sublimation amount, and low productivity of the evaporated material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

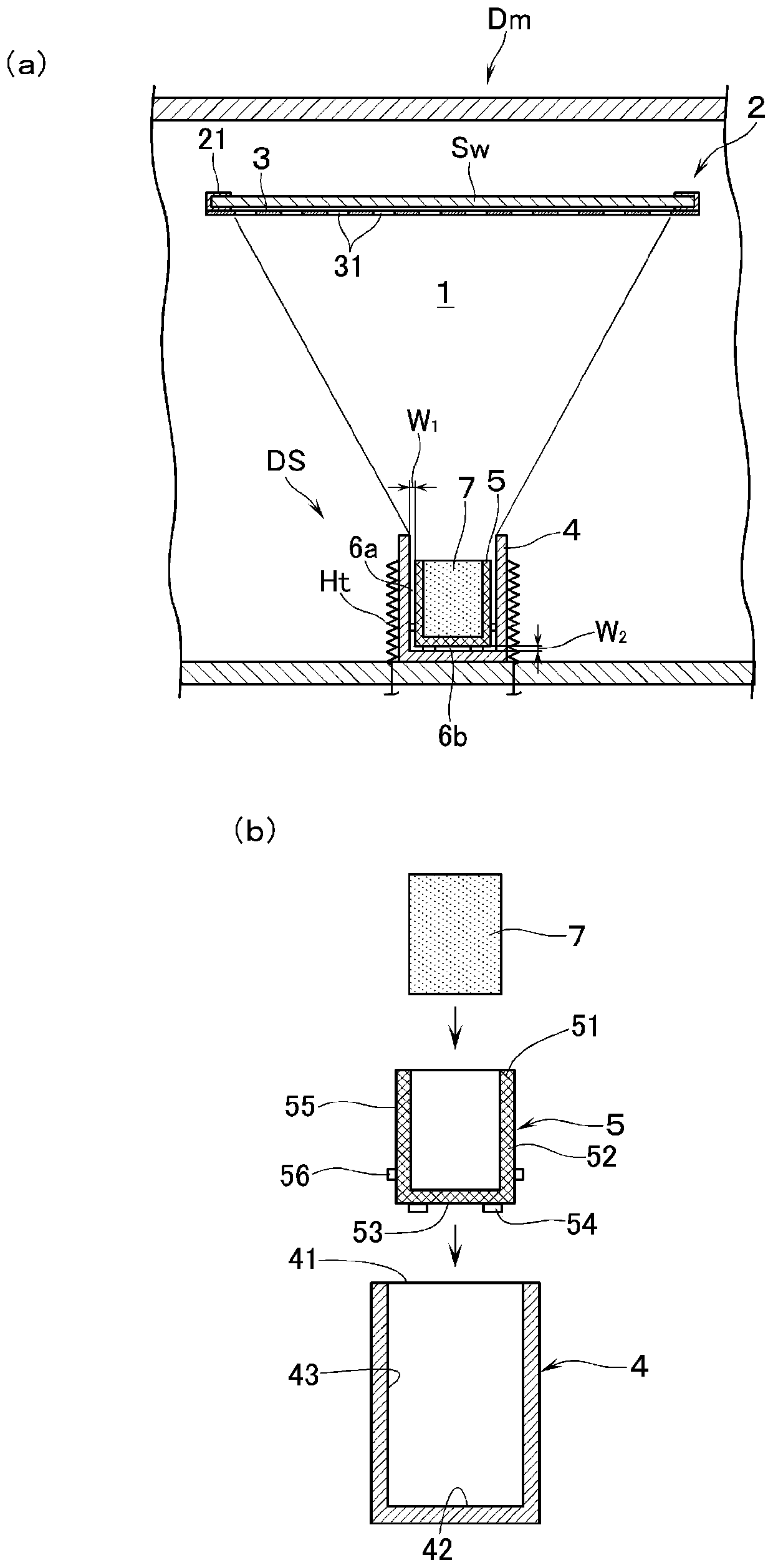

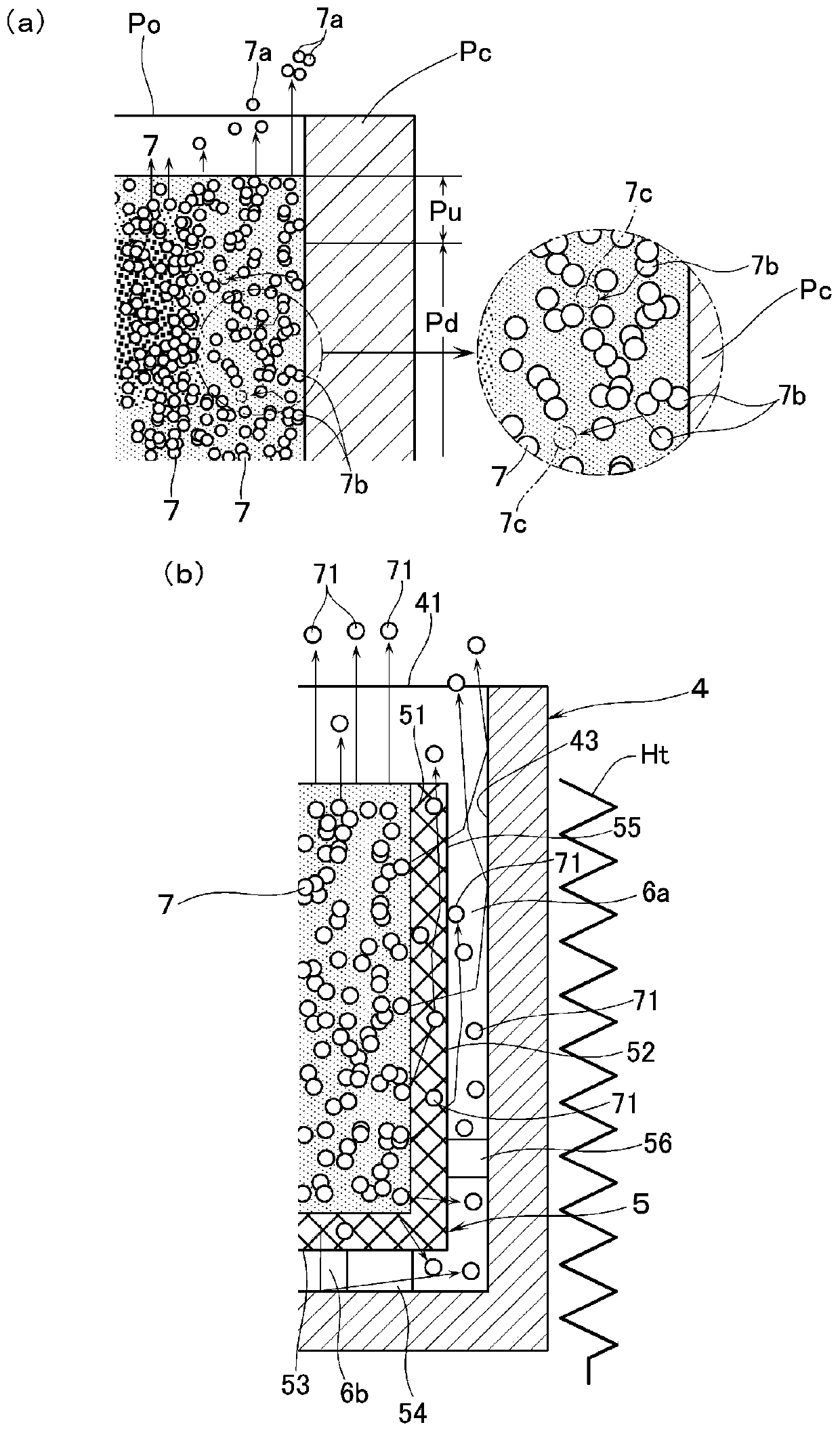

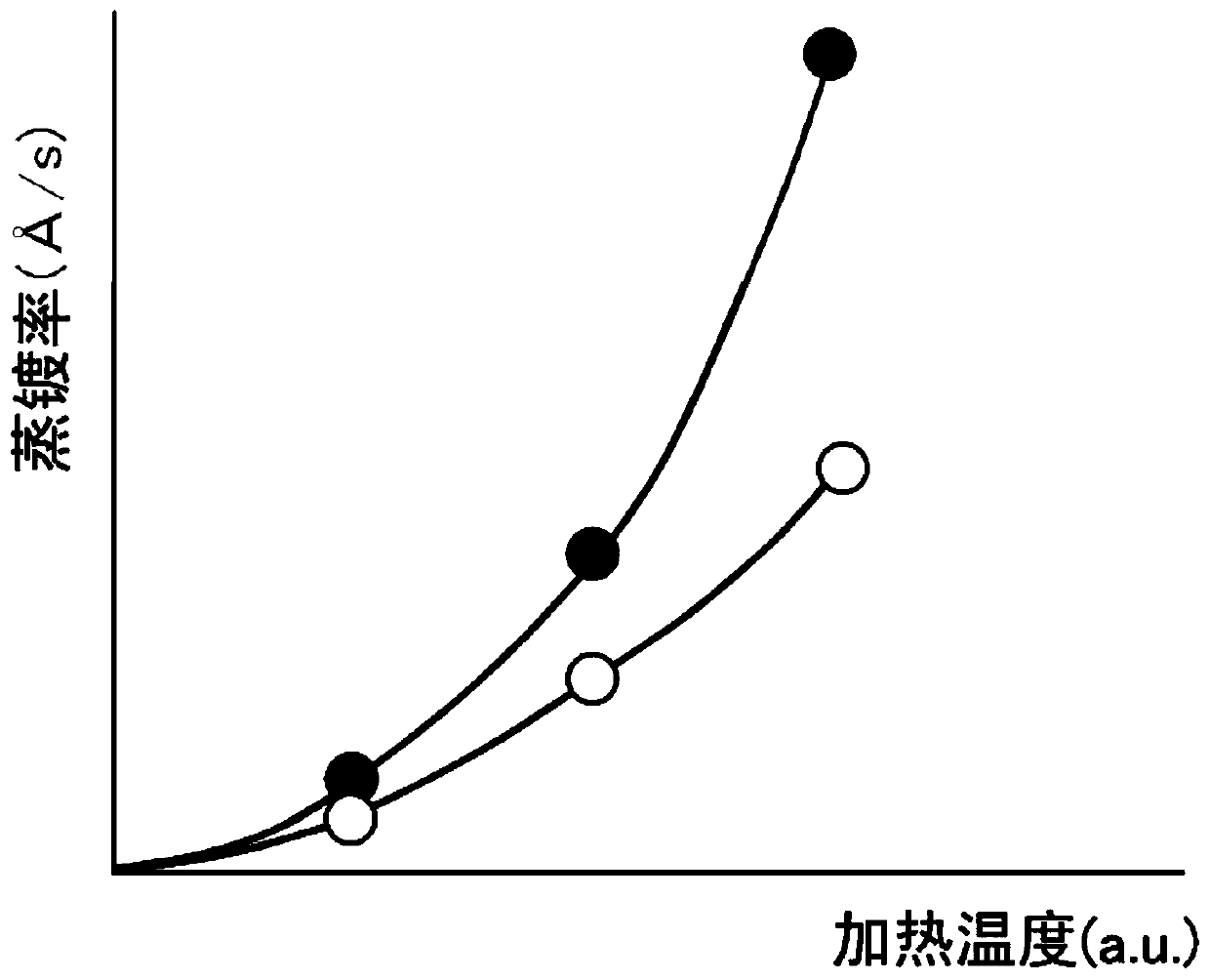

[0017] Referring to the accompanying drawings, a glass substrate with a predetermined thickness having a rectangular outline (hereinafter referred to as "substrate Sw") is used as the vapor-deposited object, and a sublimable organic material is used as the vapor-deposited substance to vapor-deposit a predetermined film on one side of the substrate Sw. Taking the case of the present invention as an example, an embodiment of the vapor deposition source for a vacuum vapor deposition device according to the present invention will be described. The following words such as "up" and "down" indicating directions are used to show the setting posture of the vacuum evaporation device. figure 1 as the benchmark.

[0018] refer to figure 1 , Dm is a vacuum vapor deposition device having the vapor deposition source DS of this embodiment. The vacuum evaporation device Dm has a vacuum chamber 1, although not illustrated in particular, but the vacuum chamber 1 is connected to a vacuum pump t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com